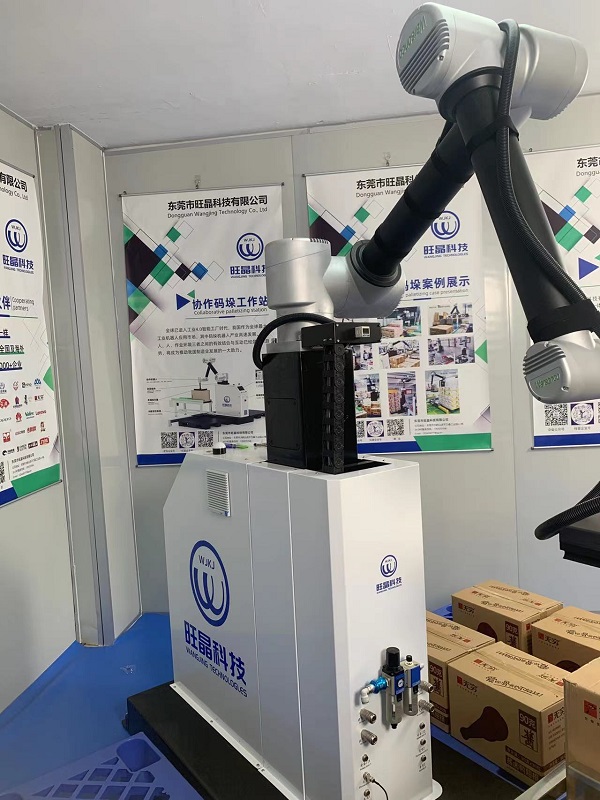

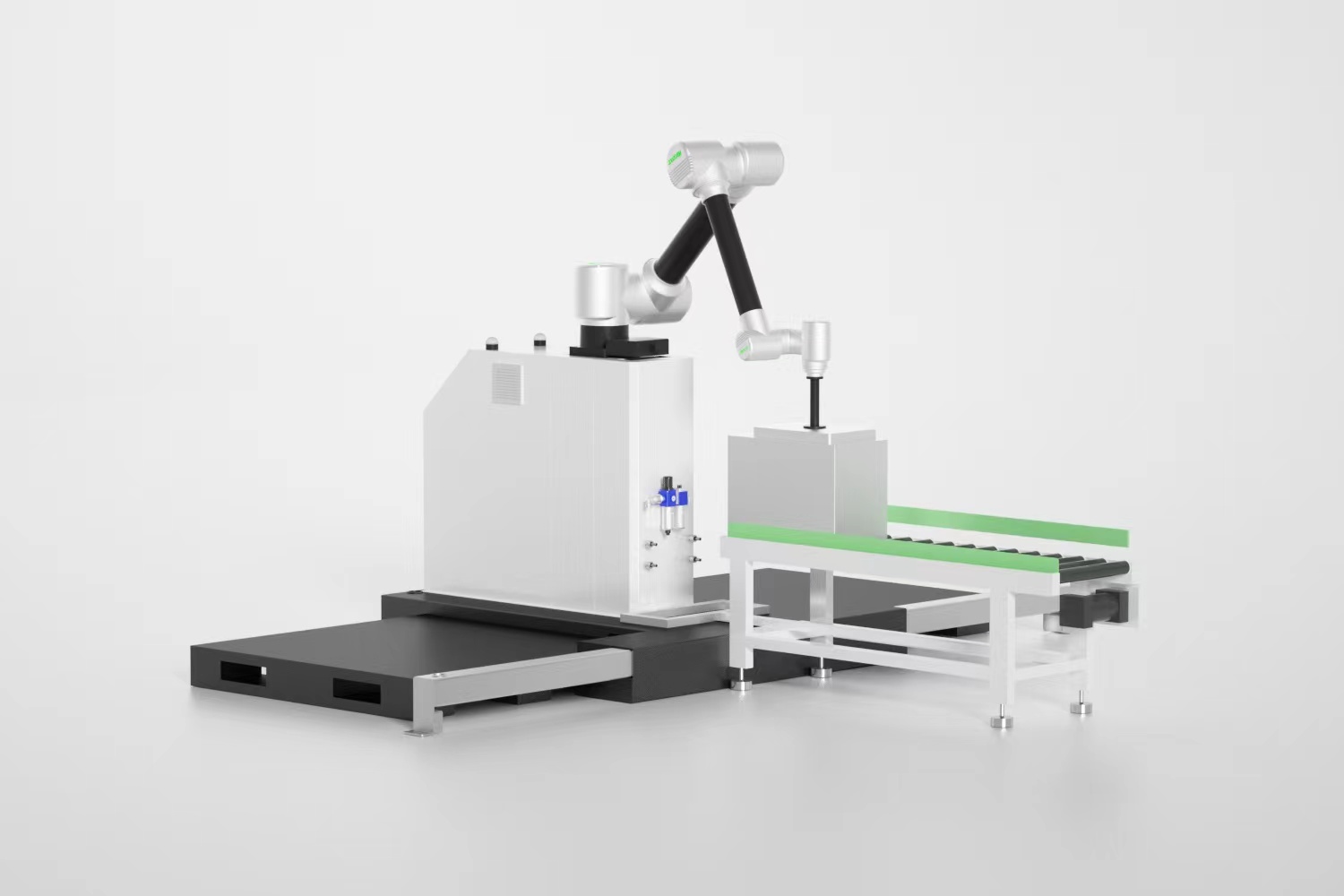

Work flow of automatic palletizer production line

The fully automatic cooperative stacker is mainly composed of leveling belt conveyor, slow stop belt conveyor, transfer belt conveyor, tray bin, tray belt conveyor, arranging machine, bag pushing machine, stacker machine and stacker belt conveyor. Its automatic design ensures stable, safe and reliable posture. The working process of the stacker is fully automatic, and there is no need for manual control during normal operation, so it has a universal application field.

Market outlook 2022-09-20

In the industrial field, the control technology of palletizing robot has these.

Compared with ordinary mechanical palletizer, the palletizing robot has the advantages of high efficiency, low failure rate and convenient maintenance, so it is widely used. The main task of palletizing robot control technology is to control the movement position, posture and trajectory, operation sequence and action time of industrial robot in the workspace. Now let's talk about the control technology of the stacking robot.

Market outlook 2022-09-27

Stacking robot slowly replaces manpower

The palletizing robot presents a diversified development trend. It can replace the staff working in dangerous, continuous high temperature, toxic and harmful substances and other harsh environments, while ensuring product quality and improving work efficiency

Market outlook 2022-09-18

We are now studying the problems faced by palletizing robots

Stacking robot is a kind of industrial robot, which is widely used at present. With the decline of labor rate and the rise of labor cost, palletizing robots are used more and more. Stackers and porters are manufactured in manufacturing enterprises to replace manual post packaging operations.

Market outlook 2022-09-28

At present, robots have been successfully applied in many industries, including the working efficien

The definition of collaboration is more widely used in industrial scenarios. The cooperative mobile palletizing robot has replaced and improved the existing industrial robots, and has become the leading technology genre in the robot field with its higher safety factor, reliability and human coordination ability.

Market outlook 2022-11-01

The robot adopts a fully automatic palletizing robot, automatic palletizing, automatic assembly line

With the development of science and technology and the shortage of labor force, many factories and workshops choose unmanned full-automatic palletizer robot for automatic palletizing, which not only saves costs, but also improves production efficiency. The automatic palletizing robot usually palletizes the bags, boxes, barrels and other materials on the production line to the hauling line according to the instructions set at the end of the production line. Finally, it is stored in the warehouse with a forklift.

Market outlook 2022-09-29

This technology is fully automatic palletizer, which is a good helper for enterprise production

Many people have only a general understanding of stackers. They believe that the stacker is a simple mechanical equipment used for handling and stacking goods. In fact, the stacker is not just a simple mechanical equipment. Many production workshops have palletizing robots to load, unload and stack goods. The use of palletizing robots is several times more efficient than traditional labor, but it can also reduce the human cost of enterprises.

Market outlook 2022-09-23

Stacker realizes unmanned factory landing in food industry

Industrial robots are the main force for "unmanned factory" to achieve production development, and also the key point for intelligent upgrading of manufacturing enterprises.

Market outlook 2022-09-15