How to improve production efficiency What are the problems faced by the palletizing robot

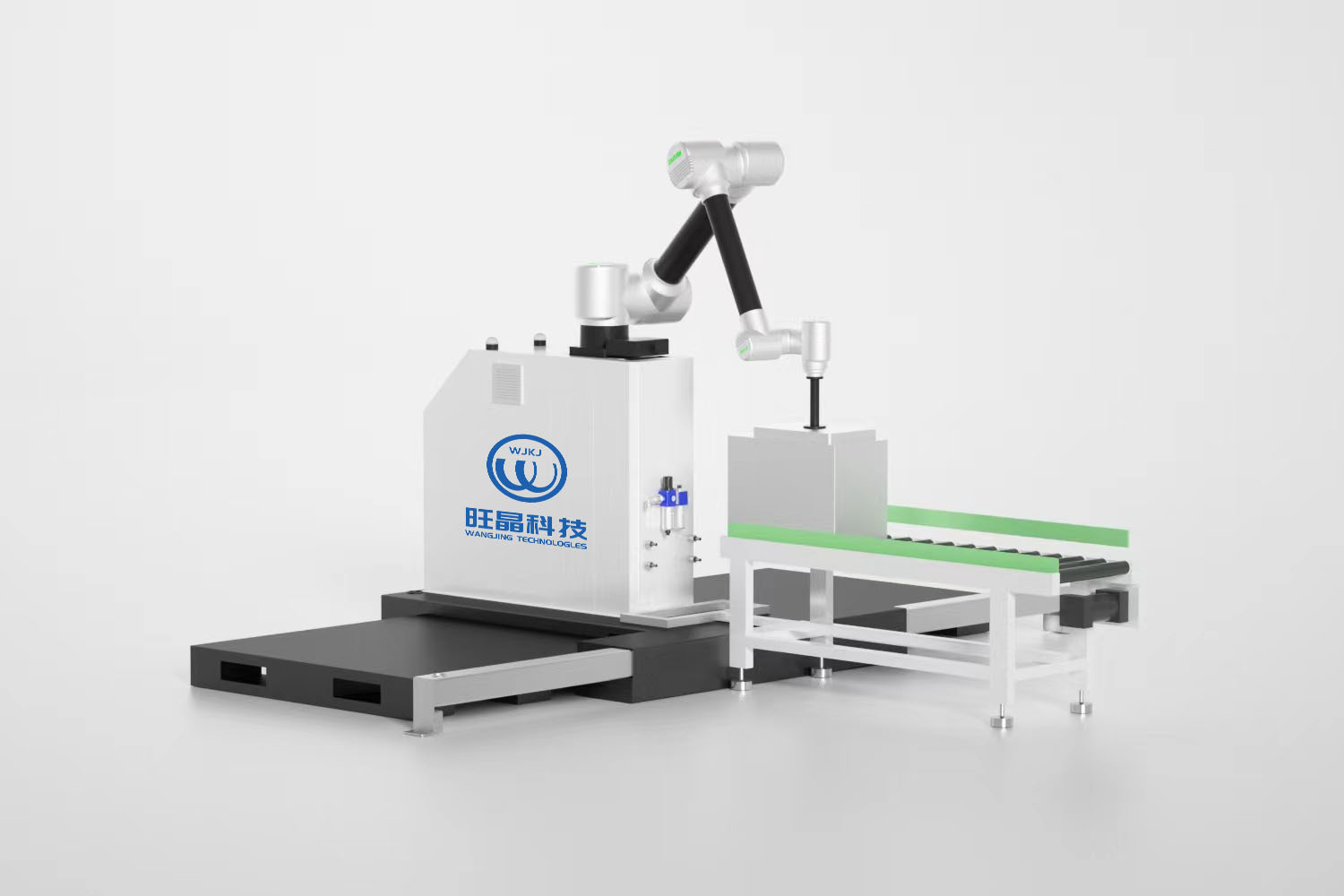

Stacking robot is a kind of industrial robot, which is widely used at present. With the decline of labor rate and the rise of labor cost, palletizing robots are used more and more. Stackers and porters are manufactured in manufacturing enterprises to replace manual post packaging operations. It can improve product quality and output, and reduce labor costs. The stacking robot has a simple and durable structure. It can work with high intensity for a long time in various environments, reduce the occurrence of industrial accidents, and integrate into various production lines. The palletizing robot has many advantages, so what are the problems it faces?

Market outlook 2022-09-27

At present, robots have been successfully applied in many industries, including the working efficien

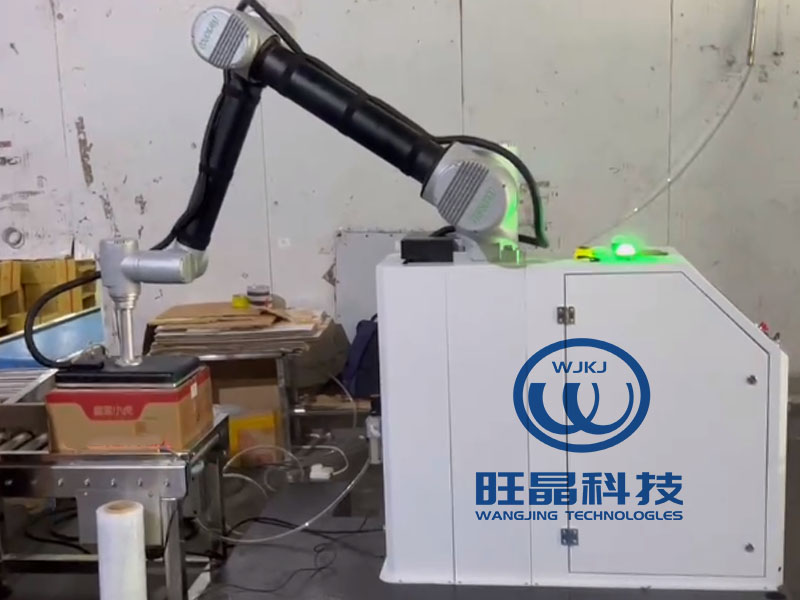

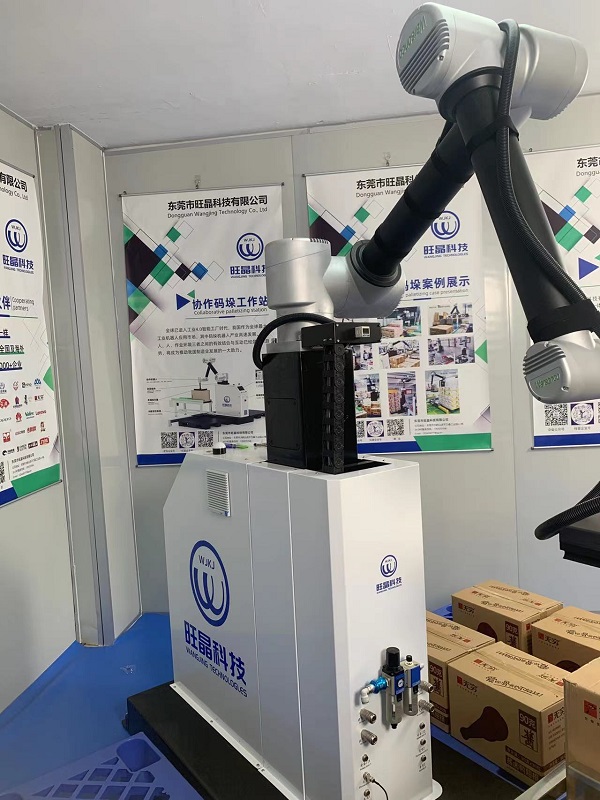

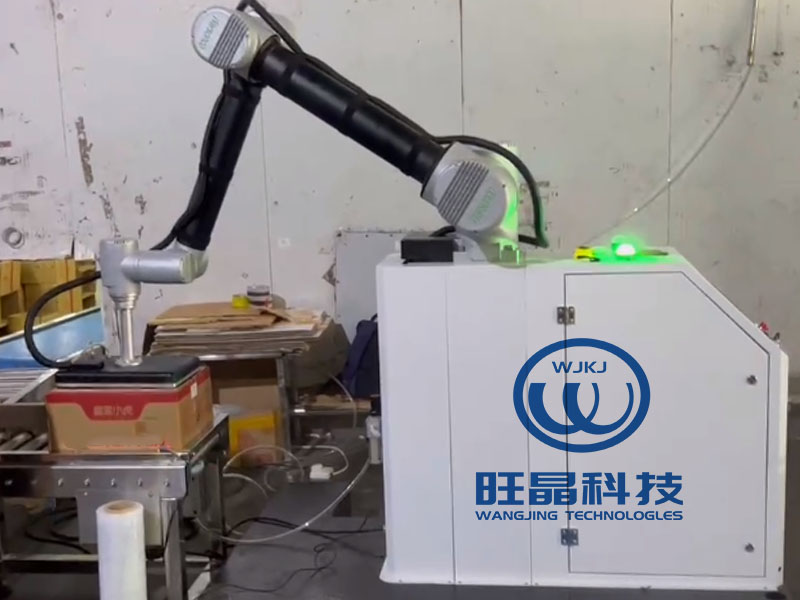

The definition of collaboration is more widely used in industrial scenarios. The cooperative mobile palletizing robot has replaced and improved the existing industrial robots, and has become the leading technology genre in the robot field with its higher safety factor, reliability and human coordination ability.

Market outlook 2022-11-01

Therefore, we believe that it is self-evident that palletizing robots can reduce human costs and enh

Stacking robot can reduce labor cost and enhance enterprise competitiveness. Due to the high demand and dependence on labor in manufacturing, the labor cost in manufacturing is relatively high. Public data shows that the human cost of most manufacturing enterprises accounts for about 38% of the enterprise income, so how to reduce the human cost and improve the competitiveness of enterprises is very important for many manufacturing enterprises!

Market outlook 2022-09-22

As an industrial robot, palletizing robot is one of the key emerging industries for China to impleme

Cooperative palletizing robot, an industrial robot, is a key emerging industry in China's implementation of the manufacturing power strategy. The development level of robot industry is an important symbol to measure a country's innovation ability and industrial development level.

Market outlook 2022-09-21

Our goal is to reduce labor costs and improve enterprise competitiveness through palletizing robots

Stacking robot can reduce labor cost and enhance enterprise competitiveness. Due to the high demand and dependence on labor in manufacturing, the labor cost in manufacturing is relatively high. Public data shows that the human cost of most manufacturing enterprises accounts for about 38% of the enterprise income, so how to reduce the human cost and improve the competitiveness of enterprises is very important for many manufacturing enterprises!

Market outlook 2022-09-23

So why are palletizing robots so popular?

With the accelerated development of industry, intelligent devices represented by industrial robots are facing unprecedented development opportunities. For many years, China has been the main consumer market of intelligent robots.

Market outlook 2022-11-08

The main application industry of automatic palletizer in this industry is automatic palletizer

In recent years, with the rapid development of food, beverage and health care industries, the intensity of manual stacking is high, and the rate of staff turnover is high, which has seriously affected the production management of food, medicine and other

Market outlook 2022-11-08

Stacker realizes unmanned factory landing in food industry

Industrial robots are the main force for "unmanned factory" to achieve production development, and also the key point for intelligent upgrading of manufacturing enterprises.

Market outlook 2022-09-15