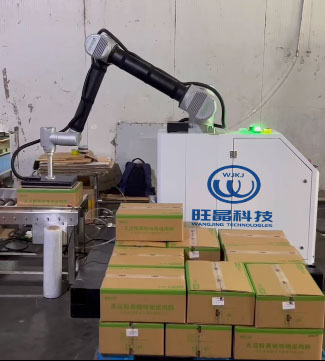

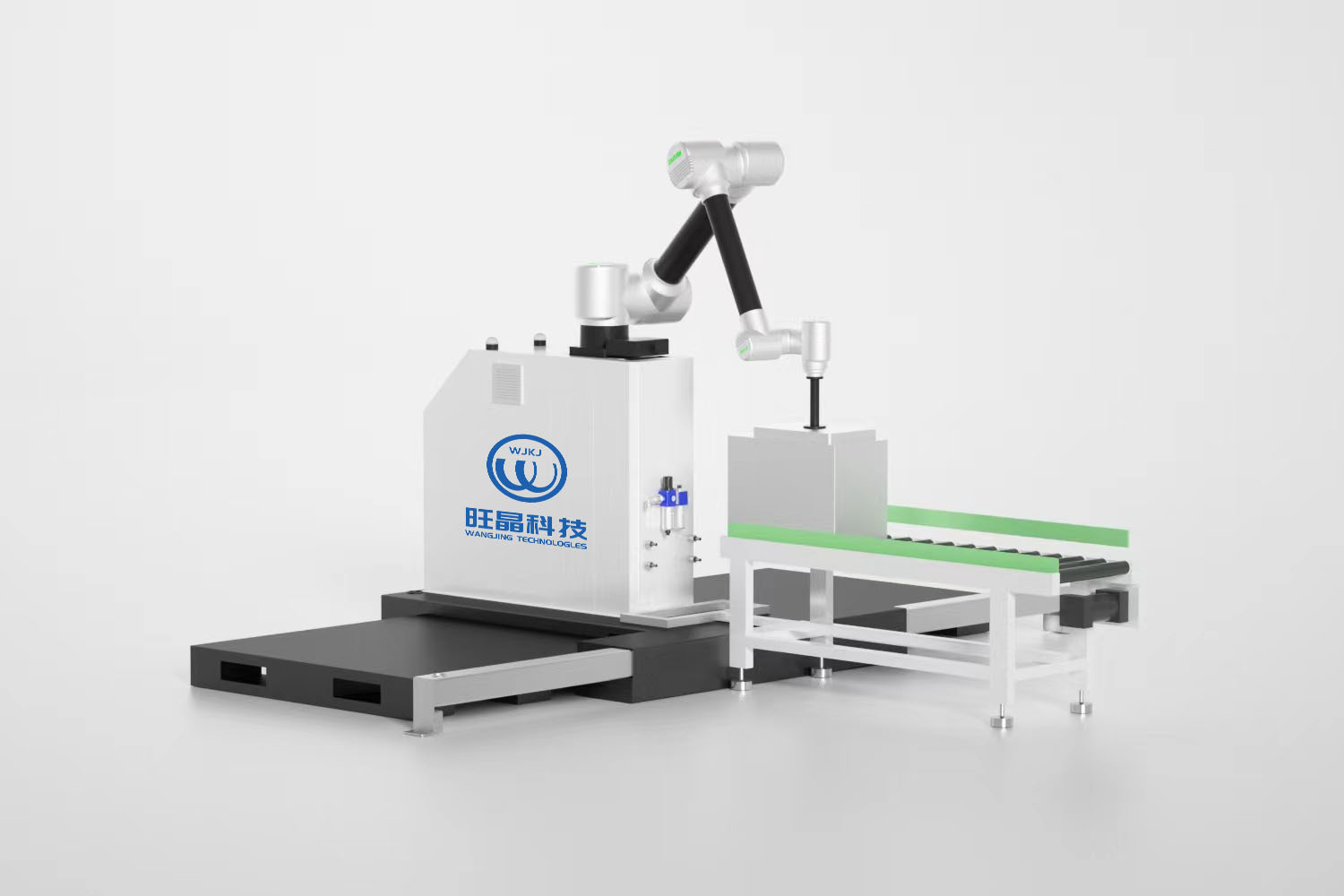

Work flow of automatic palletizer production line

The fully automatic cooperative stacker is mainly composed of leveling belt conveyor, slow stop belt conveyor, transfer belt conveyor, tray bin, tray belt conveyor, arranging machine, bag pushing machine, stacker machine and stacker belt conveyor. Its automatic design ensures stable, safe and reliable posture. The working process of the stacker is fully automatic, and there is no need for manual control during normal operation, so it has a universal application field.

The workflow of the collaborative palletizer production line is as follows

Quantitative packaging scale - portable sewing machine - vertical inverted bag transport - uphill transport - horizontal type - belt conveyor to be climbed - uphill stacker - forklift outbound - warehousing

In order to unify the standard stacker, give full play to the high efficiency of the stacker handling robot and the working capacity of the stacker, increase the lifting line, and lift the packaging bag with reversed lines to a unified standard relative height.

The fully automatic cooperative stacker has the advantages of compact structure, high working capacity, high speed and large bearing capacity. It is widely used in various production lines, such as chemical plants, grain crops, concentrated feed, etc.

The A axis of the palletizing robot is horizontal, the B axis is vertical, the C axis is its own rotation axis, and the D axis is the hand-held transmission axis.

The mechanical equipment of the stacking robot can complete the random adjustment of three lines and one machine, multiple lines and one machine, packaging, random disassembly and replacement of packaged products, random adjustment of product size, pallet position and size, stacking type of the stacking machine and other parameters according to the design scheme of the control module, flexible production, program flow and mobile phone software intelligent system of the mechanical equipment. It can be set through simple operation of the touch screen, and the robot can calculate the state of the stacker by itself.

The working efficiency of the stacker is greatly improved after being transported by the invention. It can directly save a lot of labor and greatly reduce labor costs. Under the routine system maintenance, the robot has been operating normally for more than ten years. In recent years, with the rise of automatic stacking machine production line for mass production, this kind of stacking machine system will have a more general industry prospect and development!