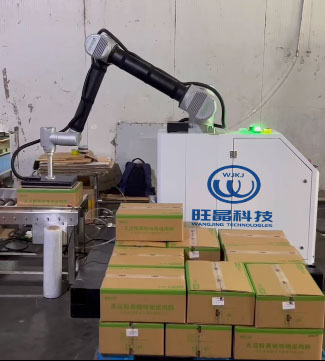

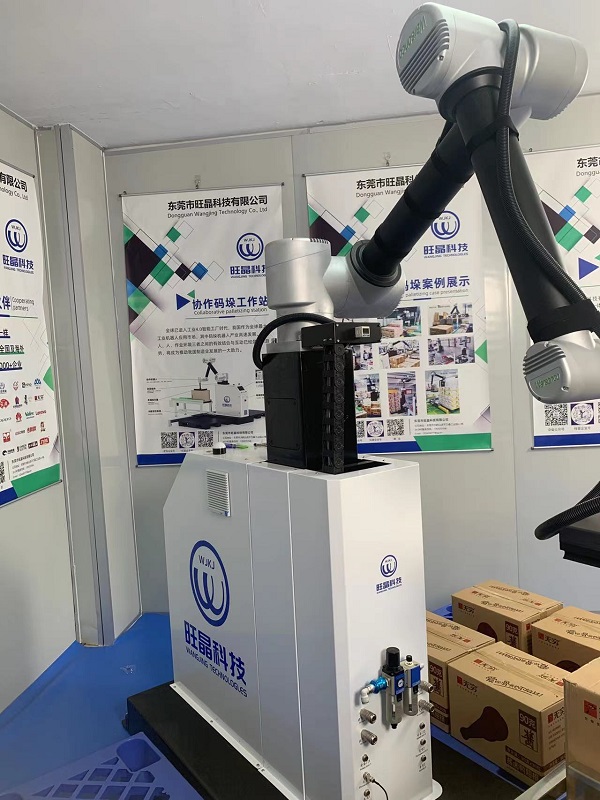

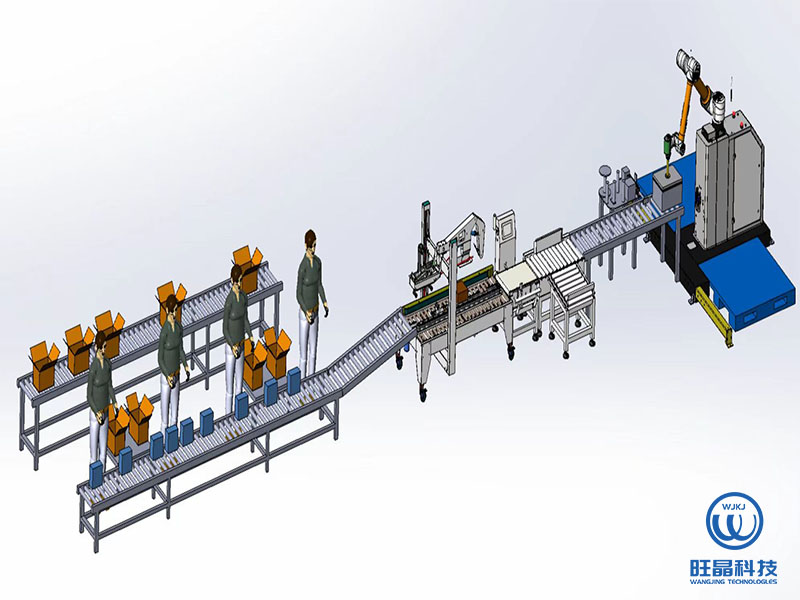

With the rapid development of intelligent manufacturing, palletizing robot has become the mainstream

With the increasing popularity of automatic robot production, the cost of robots is also decreasing. In the past 30 years, the average price of robots has actually dropped by half, even exceeding the labor cost.

As the demand of emerging economies is encouraged, the cooperative production of robots is transferred to low-cost areas, and its price may be further reduced. In addition, more and more talents are able to contact people who have the skills required to design, install, operate and maintain robot production systems. Robotic engineers used to be very rare experts, and their employment costs were very high. Today, robots are taught all over the world. They are either specialized courses in manufacturing technology or manufacturing engineering design, or part of general education.

The availability of software, such as simulation packages and offline programming systems for testable robot applications, reduces project time and risk. It also makes robot programming tasks simpler, more costly, and easier to integrate computing performance. With the development of software development technology and network technology, the speed of robot assembly, installation and maintenance has been improved, and the related costs have been reduced. For example, in the past, sensors and brakes had to be connected to robot controllers through terminal blocks, connectors and junction boxes respectively, but now plug and play technology can be used, so components can be connected through relatively simple network wiring. These components will automatically identify the control system, so the setup time can be greatly reduced.

These sensors and brakes can also monitor themselves and report their status to the control system to assist in process control, collect maintenance data, and achieve continuous improvement and troubleshooting. Other standards and network technologies also make it easier for robots to connect to a wider range of production systems, and robots with new functions become more intelligent. Early robots just blindly followed the same path.

Later versions of simultaneous interpretation systems use lasers or vision systems to detect the orientation of parts and materials. The new generation of cooperative palletizing robot can integrate information from different sensors and adjust its movement in real time. For example, this allows them to use force feedback to simulate mechanical operations in grinding, dressing, or polishing applications. They can also use more powerful computer technology and big data analysis. For example, they can check the welding quality through spectral analysis during welding, which greatly reduces the inspection work required after manufacturing.