These problems are the key to the normal and stable operation of the automatic stacker

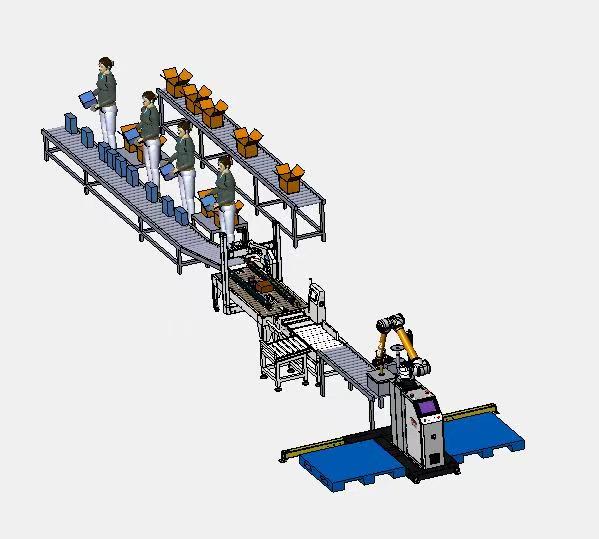

The capability of fully automatic palletizing can be easily demonstrated. Just put the weighed raw materials on the tray orderly according to the required sorting method. It only needs to be stacked neatly, not packed, not stacked upside down, indicating that the stacker meets the requirements. Naturally, in order to achieve this, the stacker must meet the preconditions of its own work, namely, switching power supply and pneumatic valve.

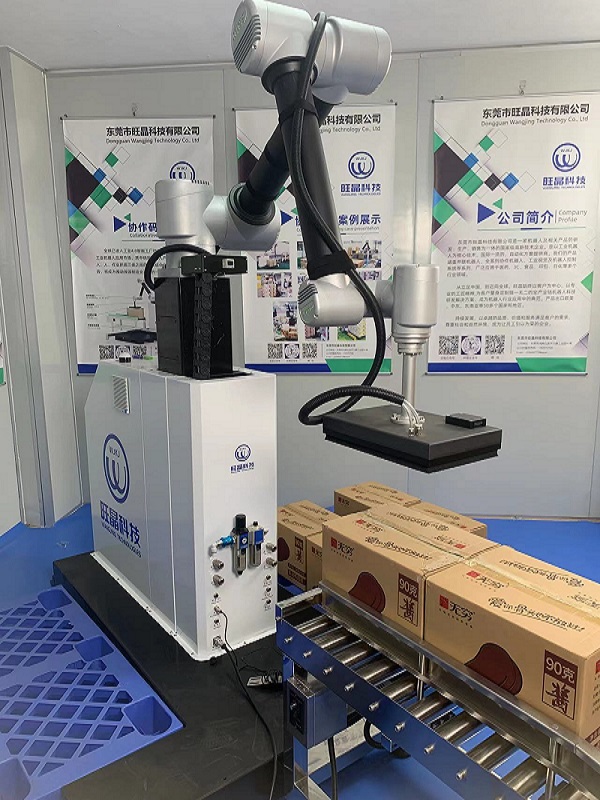

After connecting the main power supply of the stacker, it is necessary to connect the compressed air to the air source of the machine, and discharge the condensed water in the air filter screen immediately to detect and remove the dirt in the filter device; Check and adjust the air pressure of the barometer indicator, the oil leakage of the pneumatic triplet of the barometer and the capacity of the oil cup.

If everything is normal, you can go to the stacker In this process, it will go through three links: shaping, plate supply and package grabbing software. Any problem in any process indicates that there is a common fault in the stacker, which requires standardized and orderly analysis and treatment.

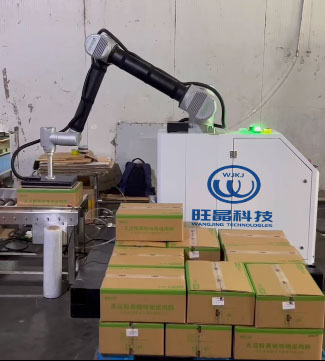

In addition to some basic components, many intelligent sensors are cross assembled in the automatic stacker. Together with the other, they also play an important role in achieving the goal of palletizing system software. As long as any sensor works abnormally, it may lead to abnormal operation of the automatic stacking system software.

In addition, the mechanical equipment is the key to the normal operation of the automatic stacker. In other words, without the normal operation of mechanical equipment, the automatic stacker may have many problems, such as the confusion of packet capturing software, the unavailability of disks, and the inability to move after completion. Electrical equipment is the key point. Without electricity and compressed air, the stacker cannot operate normally.

It is not difficult to see that the focus of the daily maintenance of the automatic stacker is the mechanical equipment and its power and compressed air, which is related to whether the mechanical equipment can work orderly, reliably and stably.