Market pattern analysis, artificial intelligence technology development and application of cooperati

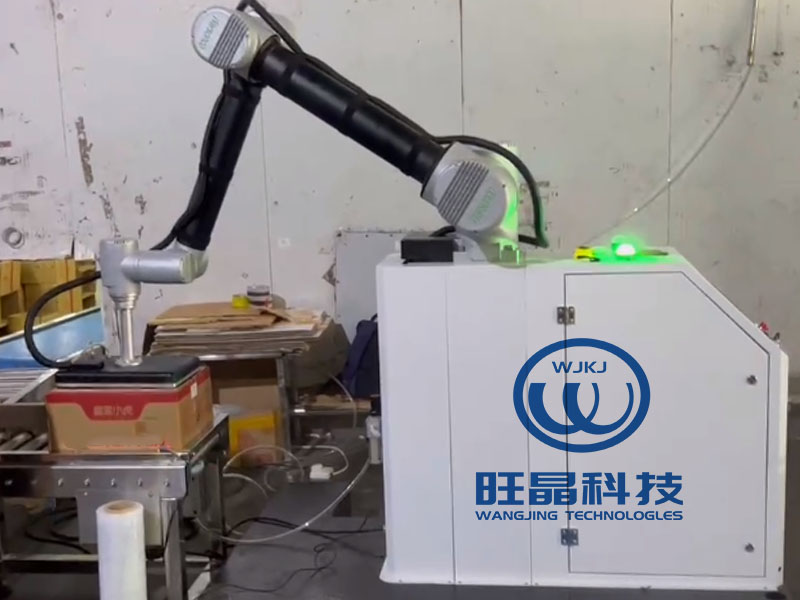

Cooperative robot is an important branch of industrial robot. The cooperative robot is mainly lightweight, and its structure is relatively simple, so the whole robot lacks rigidity. Therefore, the load of cooperative robot is generally lower than that of traditional industrial robot, and its working range is only similar to that of human arm. The application of cooperative robot products meets the requirements of precision assembly, inspection and man-machine joint operation.

Market outlook 2022-10-07

In this case, we can solve this problem by using the full automatic stacker.

Now, more and more enterprises use automatic stackers. It is worth noting that there are many skills to understand and master in the process of using automatic stackers.

Market outlook 2022-09-23

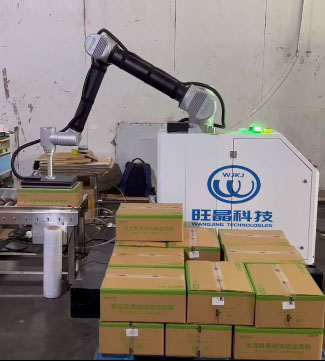

Equipment Performance and Selection of Cooperative Stacking Robot

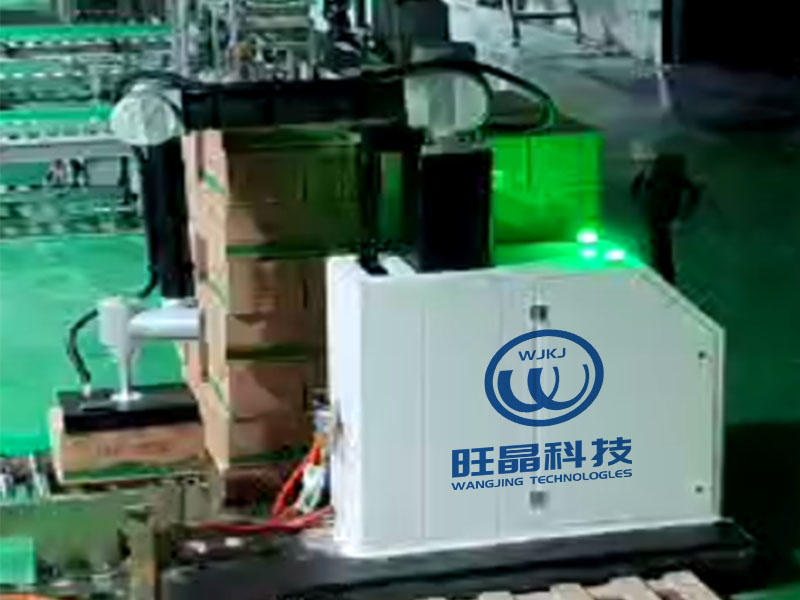

Because manual handling and palletizing cannot meet the needs of industrial production, the R&D and production of full-automatic and full-automatic handling and palletizing machines continue to accelerate. The structure of the fully automatic handling and palletizing machine is mainly composed of the power distribution cabinet, the main stacking behavior, the bag shaping and beautification, the bag body transmission, the pallet collection, the filling, handling and palletizing.

Market outlook 2022-09-20

What should we pay attention to when small and medium-sized enterprises choose cooperative robots?

Collaborative robots are used in the process of sorting out enterprise related emergencies, and can complete collaborative work that can only be completed by multiple people at a faster speed. This kind of robot is suitable for enterprises with gradual development of industrialization and scale, and can solve many difficult and complex problems. So what should enterprises pay attention to in the early stage of selecting cooperative robots?

Market outlook 2022-09-22

How to improve production efficiency What are the problems faced by the palletizing robot

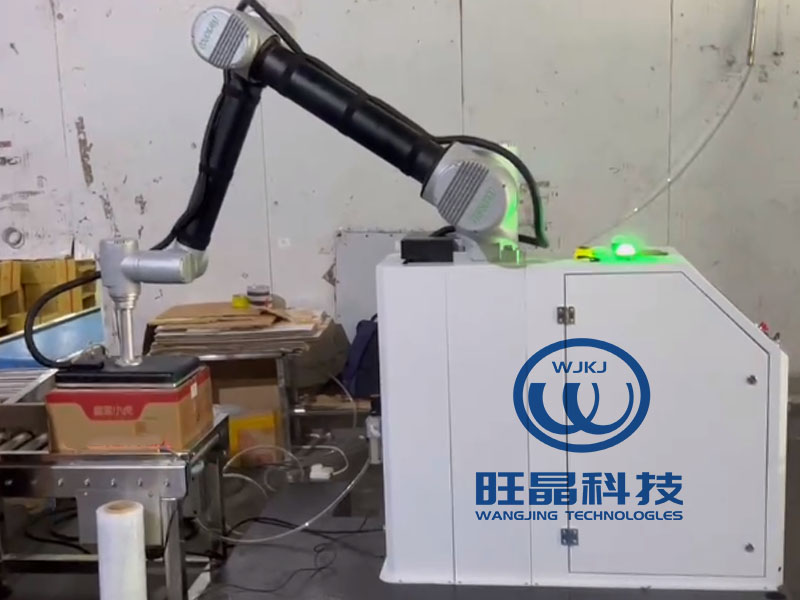

Stacking robot is a kind of industrial robot, which is widely used at present. With the decline of labor rate and the rise of labor cost, palletizing robots are used more and more. Stackers and porters are manufactured in manufacturing enterprises to replace manual post packaging operations. It can improve product quality and output, and reduce labor costs. The stacking robot has a simple and durable structure. It can work with high intensity for a long time in various environments, reduce the occurrence of industrial accidents, and integrate into various production lines. The palletizing robot has many advantages, so what are the problems it faces?

Market outlook 2022-09-27

As an industrial robot, palletizing robot is one of the key emerging industries for China to impleme

Cooperative palletizing robot, an industrial robot, is a key emerging industry in China's implementation of the manufacturing power strategy. The development level of robot industry is an important symbol to measure a country's innovation ability and industrial development level.

Market outlook 2022-09-21

With the continuous development of intelligence and informatization, the future development directio

The stacking manipulator has a material stacking sequence and arrangement setter, which simulates some action functions of the hand and arm. According to fixed procedures, it can automatically and neatly stack packaged goods of different sizes on pallets or production lines. Stacking manipulator can replace manual labor, realize mechanization and automation of production, operate in dangerous environment, and protect personal safety.

Market outlook 2022-09-23

Therefore, we believe that it is self-evident that palletizing robots can reduce human costs and enh

Stacking robot can reduce labor cost and enhance enterprise competitiveness. Due to the high demand and dependence on labor in manufacturing, the labor cost in manufacturing is relatively high. Public data shows that the human cost of most manufacturing enterprises accounts for about 38% of the enterprise income, so how to reduce the human cost and improve the competitiveness of enterprises is very important for many manufacturing enterprises!

Market outlook 2022-09-22