At present, robots have been successfully applied in many industries, including the working efficien

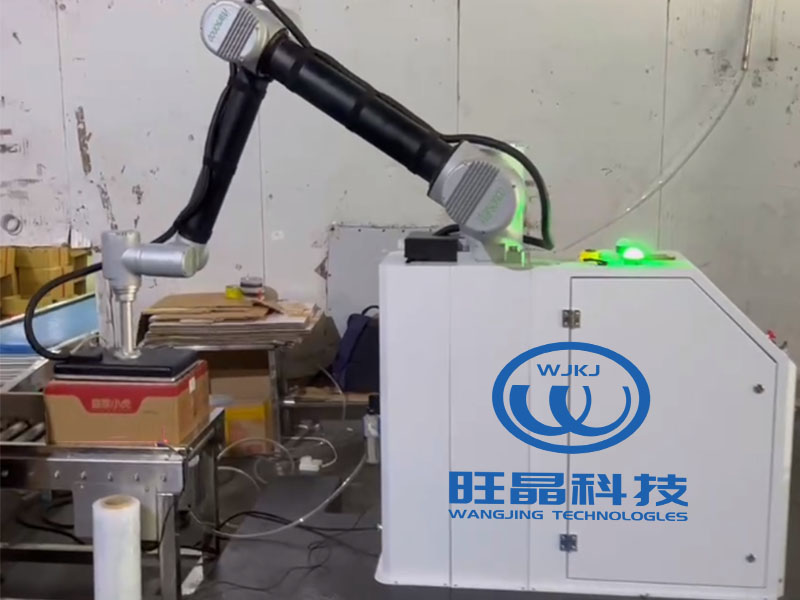

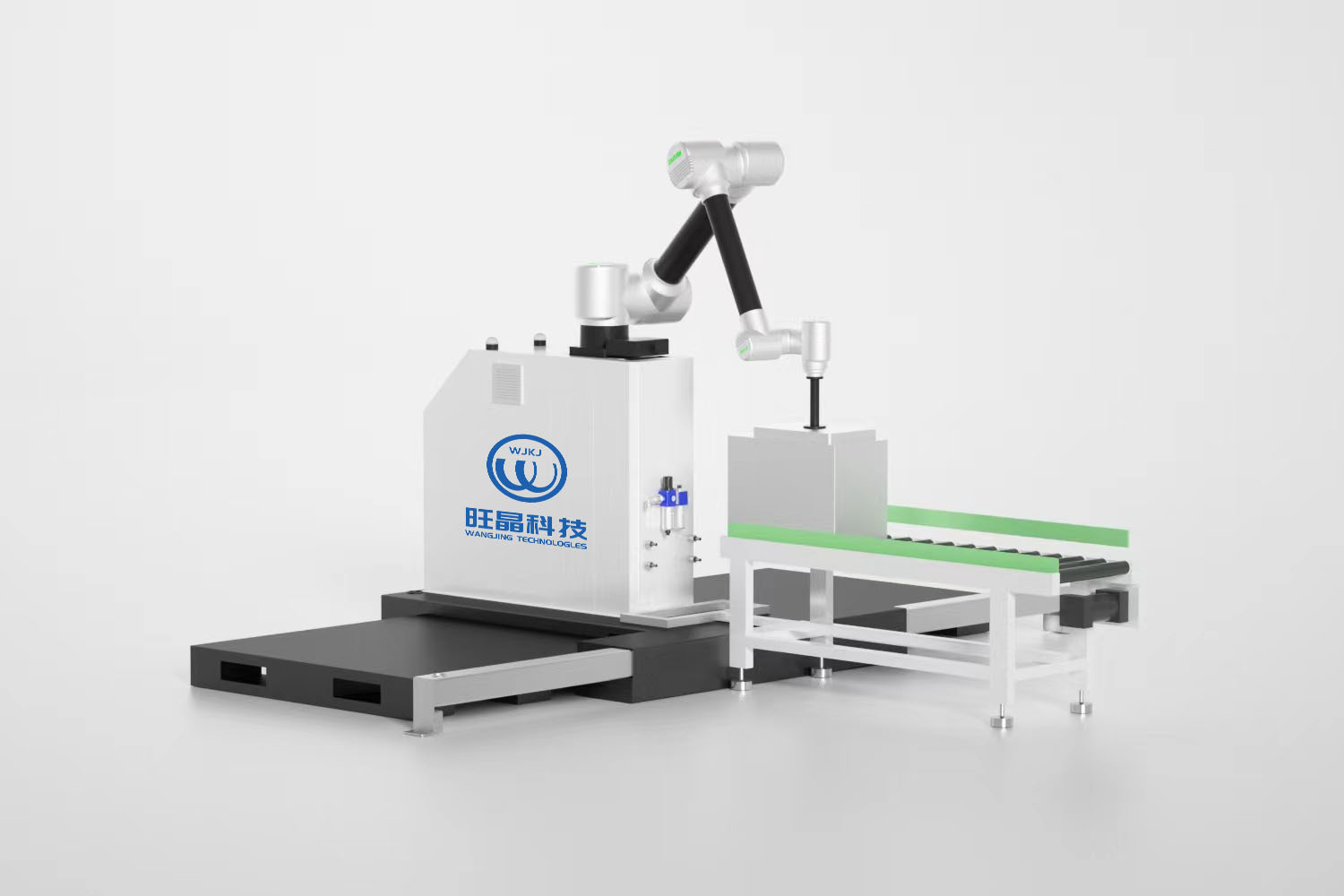

The definition of collaboration is more widely used in industrial scenarios. The cooperative mobile palletizing robot has replaced and improved the existing industrial robots, and has become the leading technology genre in the robot field with its higher safety factor, reliability and human coordination ability.

Under the definition of cooperative mobile palletizing robot, cooperative manipulator basically means that the concept of "cooperation" is not just a manipulator.

MiR clearly pointed out that man-machine combat cooperation and equipment cooperation are very meaningful concepts in the factory. As robots slowly enter a large number of places, the word "cooperation" begins to evolve in a larger scope. Now, cooperative mobile palletizing robots need to be interpreted as intelligent, fast, and close cooperation with people to jointly improve the efficiency of production lines, logistics, and warehousing in factories and other office places.

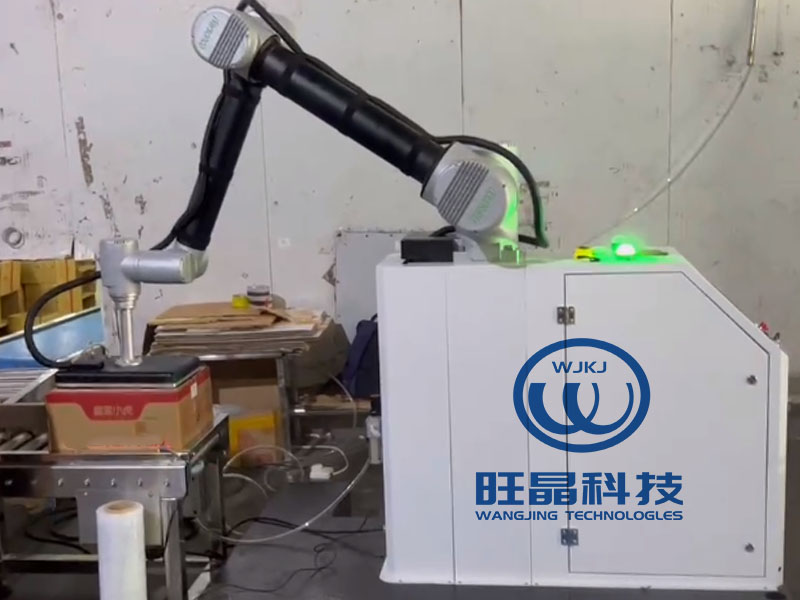

In the case of "cooperative mobile stacking robot", whether it is a mechanical arm or an independent mobile robot, the main goal is to establish the coexistence of man and machine to achieve more effective work efficiency, which challenges the convenience and safety coefficient of the robot itself.

"Whether in the vehicle, semiconductor materials, processing and manufacturing industries, or in the public service field, when considering the deployment of collaborative mobile palletizing robots, customers should first pay attention to the safety and reliability of the technology itself, especially in the living environment of mixed flow of people and vehicles such as industrial plants, or in the precise production space such as semiconductor equipment, to ensure that the robot operation has no impact risk.

Under the condition of safety, the company expects that the robot is intelligent enough to effectively boost the freight logistics of the production line and improve the work efficiency.

In addition, the openness of robot technology is also important. Only the cooperative mobile palletizing robot that can meet the requirements of intelligent production and expand its functions can be better integrated into the daily tasks of various production lines and freight logistics.