Six Advantages of Stacker Robot

Stacking robot is an intelligent robot for stacking objects. According to different product categories and actual needs, collaborative palletizing robots can be programmed to improve palletizing productivity. At present, cooperative palletizing robot has been used in various fields for a long time. What are the advantages of robot palletizing compared with other methods

Market outlook 2022-09-20

This technology is fully automatic palletizer, which is a good helper for enterprise production

Many people have only a general understanding of stackers. They believe that the stacker is a simple mechanical equipment used for handling and stacking goods. In fact, the stacker is not just a simple mechanical equipment. Many production workshops have palletizing robots to load, unload and stack goods. The use of palletizing robots is several times more efficient than traditional labor, but it can also reduce the human cost of enterprises.

Market outlook 2022-09-23

In this way, enterprises can benefit from using automatic palletizer.

Why do enterprises need to purchase automatic stackers? Is it simply because the equipment can be automated, making handling and palletizing easier?

Market outlook 2022-09-22

Now we have begun to study the application of knowledge of cooperative palletizing robot

Palletizing robot, also known as robot palletizing, is used for palletizing instead of manual operation, which can greatly improve work efficiency. In addition, the robot stacker can run for a long time, reducing the labor cost. Working principle of the stacker: place a layer of workpieces that meet the pallet requirements on the flat plate. And the flat piece moves forward to the vertical plane of the pallet. The upper stop rod drops, another tee positioning stop rod begins to clamp, and then the sheet is reset. Each workpiece shall be lowered to the pallet plane, the distance between the pallet plane and the bottom of the plate shall be 10mm, and the pallet shall be lowered by one workpiece height. Repeat the above steps until the pallet stacking meets the setting requirements.

Market outlook 2022-10-06

Characteristics of cooperative palletizing robot

Cooperative palletizing robot has brought fundamental changes to the future industrial production and factory manufacturing, and cooperative palletizing robot has decisive and important advantages

Market outlook 2022-09-18

Equipment characteristics of cooperative palletizing robot production line

It is applicable to the collaborative palletizing robot production line, chemical plants, pharmaceutical industry, grain crops, fertilizer, food, decorative building materials, beverages, metallurgical industry, fire-resistant insulation materials and other fields, and can be used for fully automatic packaging and palletizing of bags, full boxes, barrels, cans, and boards. The palletizing robot production line is one of the indispensable packaging equipment in today's production line. Its basic function is to stack products and package and transport them normally.

Market outlook 2022-09-18

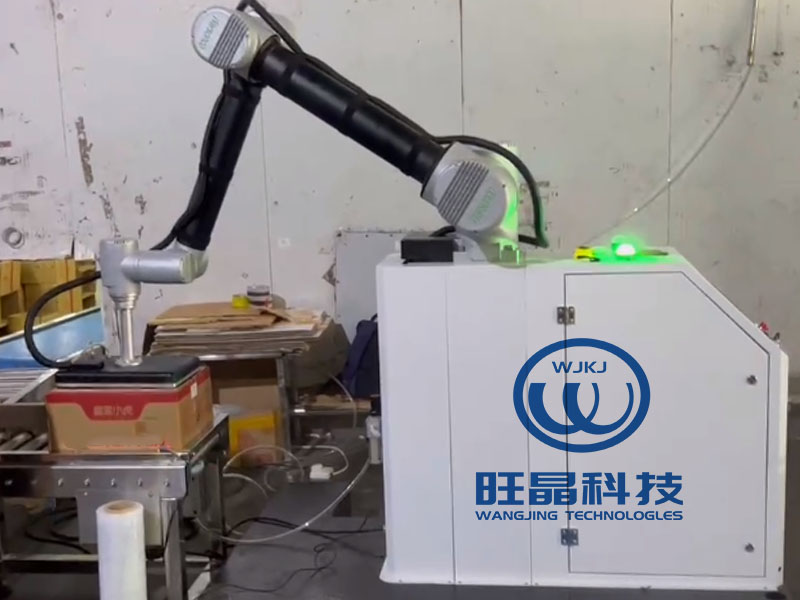

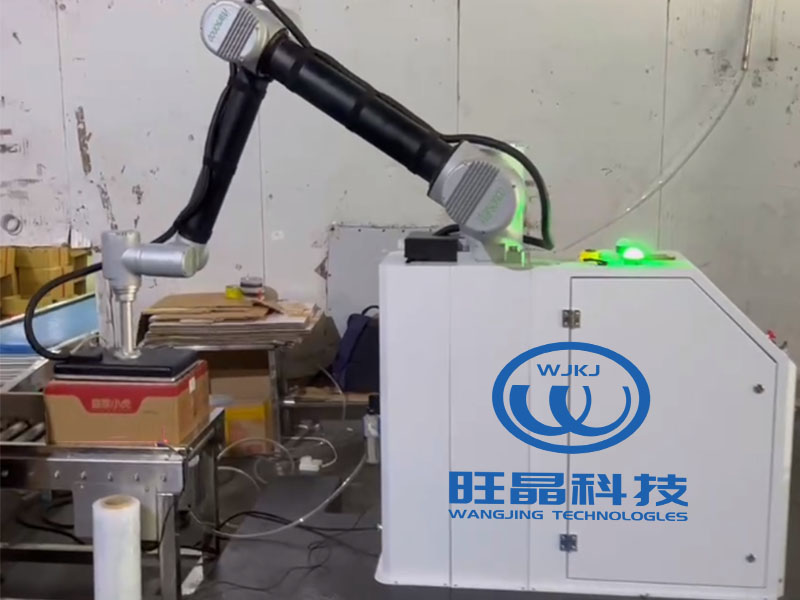

This 3D destacking robot realizes hybrid destacking automation and can realize multiple processes

In recent years, a variety of warehouse automation machines and equipment have appeared in China. How to use automated machines to improve the efficiency of warehousing operations and reduce labor seems to be the concern of the warehousing industry at this stage. From process planning to software and hardware design, the specific conditions of the construction site should be fully considered. The invention can improve the limit under complex scenes and achieve efficient operation

Market outlook 2022-11-01

As an industrial robot, palletizing robot is one of the key emerging industries for China to impleme

Cooperative palletizing robot, an industrial robot, is a key emerging industry in China's implementation of the manufacturing power strategy. The development level of robot industry is an important symbol to measure a country's innovation ability and industrial development level.

Market outlook 2022-09-21