In this way, enterprises can benefit from using automatic palletizer.

Why do enterprises need to purchase automatic stackers? Is it simply because the equipment can be automated, making handling and palletizing easier?

Of course not. If the automatic palletizing machine can only bring such benefits to enterprises, few enterprises are willing to pay a large price for these automatic palletizing machines, then what are the advantages of automatic palletizing machines for enterprises?

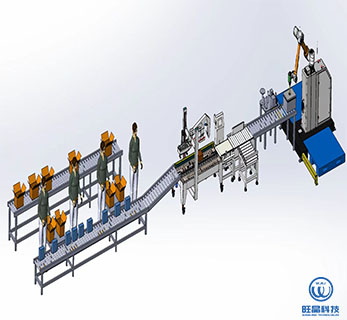

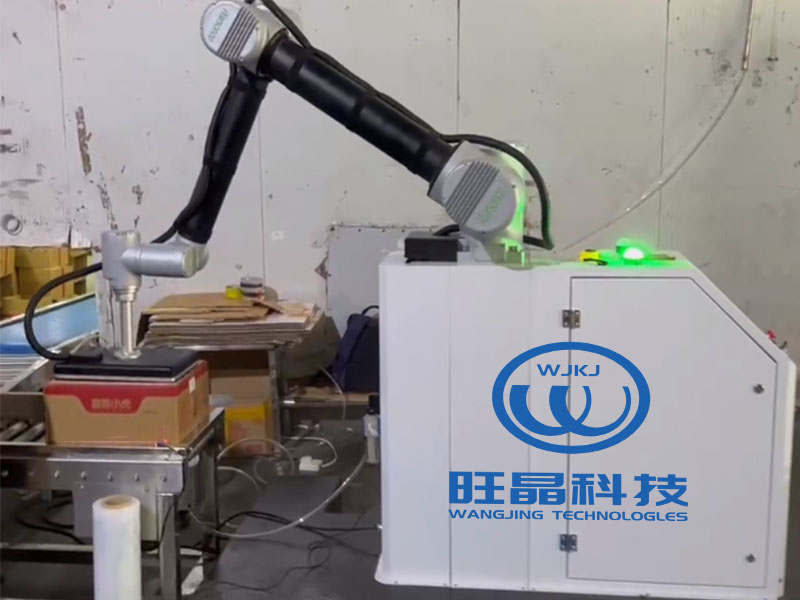

1. Improving stacking efficiency is the basic advantage of automatic palletizer. The automatic stacker can reasonably allocate the stacking quantity according to the actual stacking demand, and can improve the stacking speed and quality at the same time. It can complete a large number of palletizing in a short time.

2. In the process of stacking, a large amount of waste materials will be produced on the belt, which is often troublesome to be handled by traditional stacking equipment. However, the new automatic stacker is equipped with an automatic waste return system. Part of the waste generated on the belt of the stacker can be automatically separated from the belt and returned to the material return system to achieve automatic waste disposal.

3. Strong adaptability and changeable functions are also important advantages of automatic stacker. In the process of stacking, the stacker can automatically adjust various parameters according to different materials and stacking requirements, effectively grasp the number and spacing of stacking, and ensure that the product quality will not be damaged.