Six Advantages of Stacker Robot

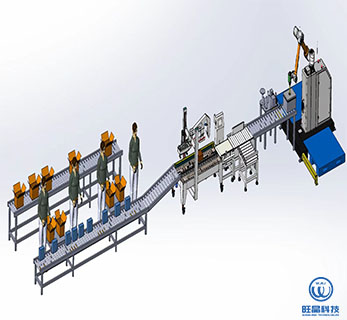

Stacking robot is an intelligent robot for stacking objects. According to different product categories and actual needs, collaborative palletizing robots can be programmed to improve palletizing productivity. At present, cooperative palletizing robot has been used in various fields for a long time. What are the advantages of robot palletizing compared with other methods

1. The cooperative palletizing robot has a large operating range, good safety factor, and only one motor in a straight line, which has a good palletizing effect.

2. The stacking robot operates in an open environment. It has an independent mechanical structure, and it uses parallel transport tracks, so it is very stable, and the transmission system efficiency is quite high.

3. The cooperative palletizing robot adopts straight slide rails, and the belt conveyors are all belt standard parts. If they are damaged, it is very convenient to purchase and disassemble them.

4. There are many kinds of goods for collaborative palletizing robots, ranging from low speed to high speed, so it is also common to choose categories.

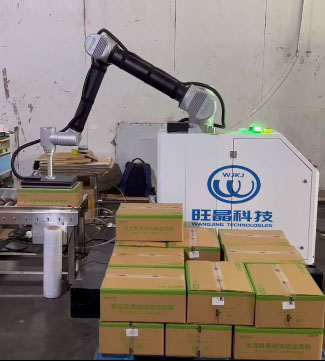

5. Most parts of the palletizing robot are at the bottom, and the arm is handy, with slow power consumption, energy conservation and environmental protection. And even in the high-speed operation environment, the stability is also high.

6. The palletizing robot has a wide range of types, specifications and models, which can be used in various conditions and a wide range of applications.

The application of the cooperative palletizing robot not only improves the working efficiency of the outer packaging, but also improves the working efficiency of the company and reduces the product cost, labor cost and capital investment of the company due to its simple operation mode and convenient maintenance in the middle and late stages. It is precisely because of these advantages that industrial robots are used by more and more enterprises, and continue to create use value for the development of enterprises.