Advantages of industrial palletizing robot

The cooperative palletizing robot has developed rapidly in many fields with its own advantages, and it often appears in many industries. The palletizing robot has the characteristics of complete models and specifications, stable operation, low energy consumption, simple operation, and high automation level, which improves the automation level of palletizing and is beneficial to easing the labor force.

Market outlook 2022-09-19

Our palletizing robot has many advantages

The operation of the palletizing robot is very simple, just set the picking position and tray position, and then design the running track to place the operation robot. The stacking position adjustment is also very simple, and can be directly operated on the touch screen. If you want to change another product, just input the specifications of the new product into the system.

Market outlook 2022-09-23

The advantage of this robot is that it can automatically identify what is a cooperative palletizing

The stacking work is completed in the form of a mechanical arm. Stacking is one of the most promising cooperative robot applications, but before introducing in detail, let's start with a simple definition. Palletizing or palletizing refers to the act of placing products on pallets for shipment or storage in the logistics supply chain. Ideally, products should be stacked in a way that maximizes the weight and volume of products under load, and they should be stable enough to prevent products from moving, dumping or squeezing each other.

Market outlook 2022-10-06

Innovation leads technology enabling/technology leads "intelligence" to build the future

With the continuous development and change of society, more and more enterprises have clearly realized that science and technology and innovation have become the most strategic key variables in the development of countries around the world. Who has mastered advanced science and technology can have greater voice in the market. Especially in the face of the severe reality that "Made in China" has been suppressed and contained in the international market, the power of science and technology and innovation is more important.

Market outlook 2022-09-22

With the development of Internet technology, Internet technology is also making continuous progress.

The birth of the palletizing robot has affected the traditional handling mode, freeing workers from high-intensity and monotonous operations.

Market outlook 2022-11-03

Main application industries of cooperative stacker

In recent years, with the rapid development of food, beverage and health care industries, the intensity of manual stacking is high, and the rate of staff turnover is high, which has seriously affected the production management of food, medicine and other industries. With the development of science and technology, the emergence of automatic palletizing machine saves the time of product palletizing and helps enterprises to complete the transportation task better. Now let's take a look at the main application fields of automatic stacker

Market outlook 2022-09-29

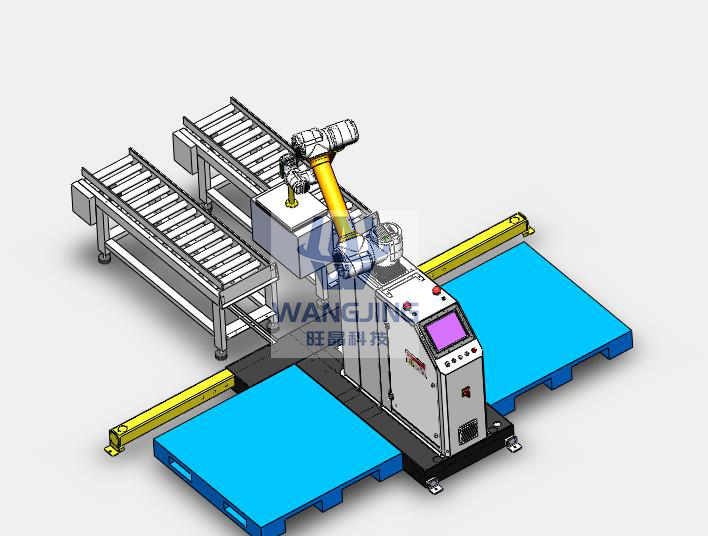

Equipment characteristics of cooperative palletizing robot production line

It is applicable to the collaborative palletizing robot production line, chemical plants, pharmaceutical industry, grain crops, fertilizer, food, decorative building materials, beverages, metallurgical industry, fire-resistant insulation materials and other fields, and can be used for fully automatic packaging and palletizing of bags, full boxes, barrels, cans, and boards. The palletizing robot production line is one of the indispensable packaging equipment in today's production line. Its basic function is to stack products and package and transport them normally.

Market outlook 2022-09-18

What are the benefits of using the fully automatic stacker

With the emergence of automatic stackers, stackers are more and more widely used in our lives. Do you know the advantages of using automatic stackers?

Market outlook 2022-09-29