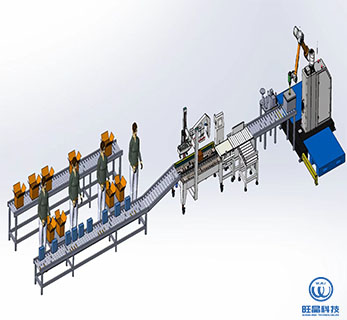

How to optimize the workflow and how to use these cooperative mobile palletizing robots

Collaboration brings into full play the role of many industries to improve the whole process. Packaging robots are generally used for light practical operations to put objects or services into small boxes or pallets. The software of the cooperative stacking robot system has a compact and streamlined design, which can provide the stacking of small precision and speed boxes, water bottles, packaging bags, trays and cartons from medium to large payloads to super heavy payloads

Market outlook 2022-10-12

In the field of industrial robots, what are the application scenarios of intelligent manufacturing a

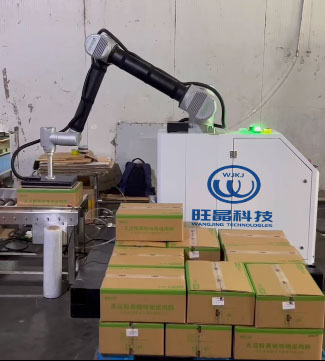

The important role of cooperative palletizing robot is to reduce the cost of manual logistics and facilitate the grabbing, handling and placing of goods.

People often find them in various express collection points, factories and other industrial scenes.

In recent years, with the cooperative mobile palletizing robot system becoming more efficient, fast and accurate software, cooperative mobile palletizing robot has been gradually applied in many companies.

Market outlook 2022-10-31

Digital transformation has become the inevitable trend of the development of the industrial Internet

Mass production of products in all industries is inseparable from palletizing In the past, we relied on manual palletizing. More than ten people completed the handling and stacking work together. High labor intensity, low stacking quality and high turnover rate are not conducive to health. With the rapid development of modern science and technology, labor shortage and rising labor costs, robot handling and palletizing production has been widely used, promoting the development of the industry.

Market outlook 2022-09-21

With the continuous development of artificial intelligence technology, enterprises will benefit more

The use of automated production lines for mass production in enterprises can improve labor productivity, stabilize and improve product quality, improve working conditions, reduce production floor space, reduce production costs, shorten production cycle, and ensure production balance, which has significant economic benefits.

Market outlook 2022-10-11

At present, what are the factors we need to consider in selecting industrial cooperative robots? How

For an old bird in the automation industry, a senior mechanic, and an electrician, selecting a suitable "robot" may be a simple task. But for those designers or factories who are ready to purchase and import robots for the first time, there may be some confusion.

Market outlook 2022-10-08

With the development of Internet technology, Internet technology is also making continuous progress.

The birth of the palletizing robot has affected the traditional handling mode, freeing workers from high-intensity and monotonous operations.

Market outlook 2022-11-03

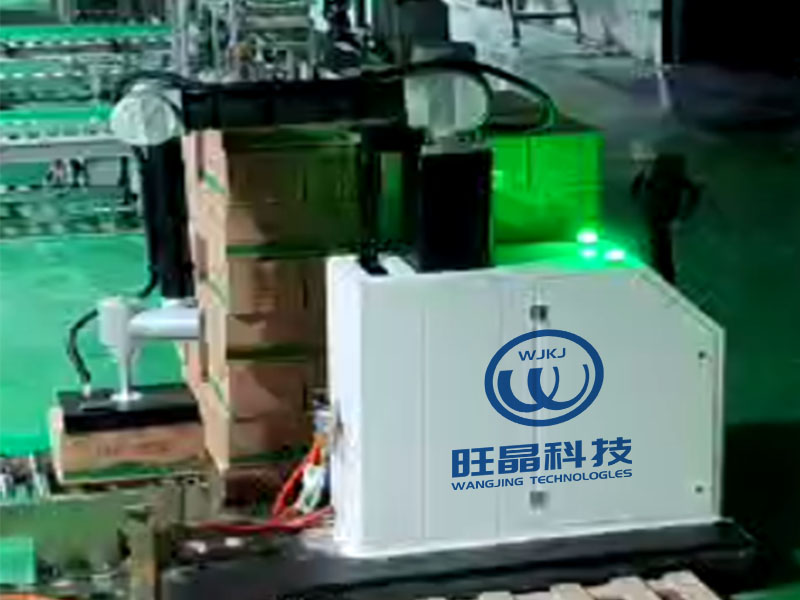

What is the working principle of palletizing robot

In our daily life, we often see or use palletizing robots. Just like when we go to the supermarket, many goods have to be put in high places. Some are manual and some are automatic. If manual operation is used, it is generally used in some small supermarkets, large malls, etc. However, in some large shopping malls or warehouses, it is not realistic to change the labor force. At this time, we need to set some programs to let the palletizing robot put in a specific position according to the set program.

Market outlook 2022-11-03

What are the characteristics of this automatic production line operation mode

The automatic packing machine can automatically arrange the products according to the packaging requirements. It is an intelligent automatic packing machine. What are the characteristics of automatic production lines? The combination of four-bar linkage, motion, landing and electrical control realizes automatic coordination and action

Market outlook 2022-10-11