With the continuous development of artificial intelligence technology, enterprises will benefit more

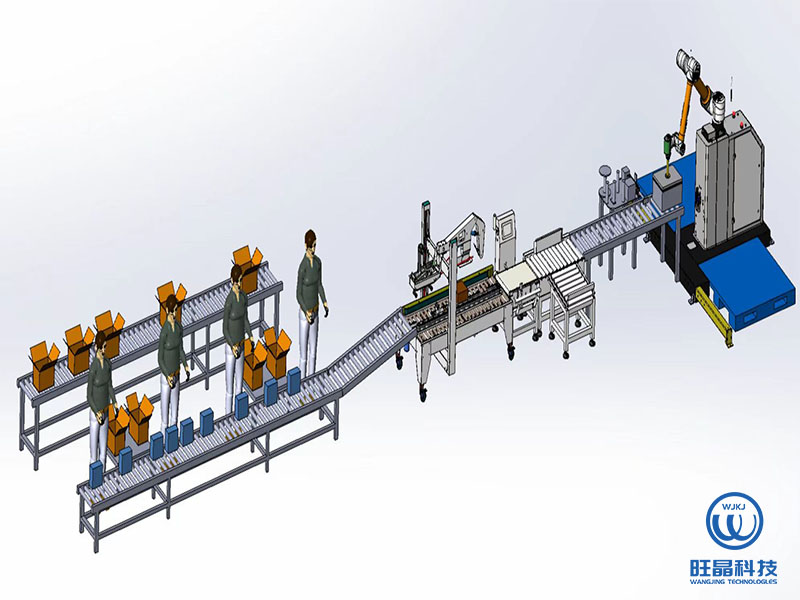

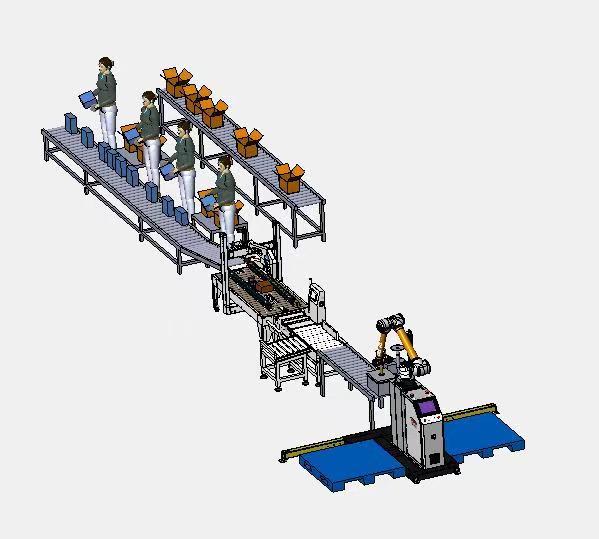

The use of automated production lines for mass production in enterprises can improve labor productivity, stabilize and improve product quality, improve working conditions, reduce production floor space, reduce production costs, shorten production cycle, and ensure production balance, which has significant economic benefits.

一、 The automatic production line is applicable to the following production enterprises

1. Finalized and mass produced products with a certain production cycle; Such as automatic packing machine production line, non-standard production line;

2. The product structure is convenient for transportation, automatic loading and unloading, positioning and clamping, automatic processing, assembly and testing;

3. The product structure is complex, there are many processing procedures, the process route is too long, the designed automation equipment subsystem is too complex, the structure is too complex, the body is too large, it is difficult to control, or even can not guarantee the product processing quantity and quality;

4. Production process based on packaging and assembly technology. Such as folding machine, sealing machine, inkjet printer, packaging machine;

5. Due to the influence of processing methods, means, environment and other factors, it is not suitable to use automatic equipment for production, but can be designed as an automatic production line.

二, automated production lines are suitable for mass production, reducing production costs and improving efficiency.

The output of automatic production line is much higher than that of manual production line. The use of automated production lines can significantly improve labor productivity and reduce costs. When the supply and demand are relatively large, we can work for a long time with high efficiency, so we can take it easy. When people put automation into some hard physical work or monotonous assembly line production, there is no tiredness and tiredness of human operators in the automated production line, which is the main factor to reduce the productivity of human operators in this production work. Automatic production lines liberate people from heavy physical labor and monotonous work, and greatly improve production efficiency.