With the development of Internet technology, Internet technology is also making continuous progress.

The birth of the palletizing robot has affected the traditional handling mode, freeing workers from high-intensity and monotonous operations.

In recent years, the palletizing robot has shown a diversified development trend. It can replace the staff working in dangerous, continuous high temperature, toxic and harmful substances and other harsh environments, while ensuring product quality and improving work efficiency.

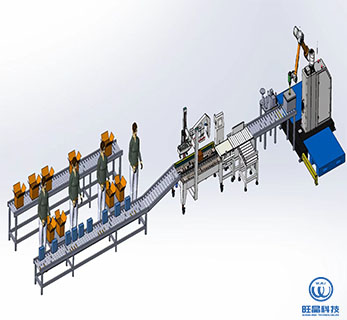

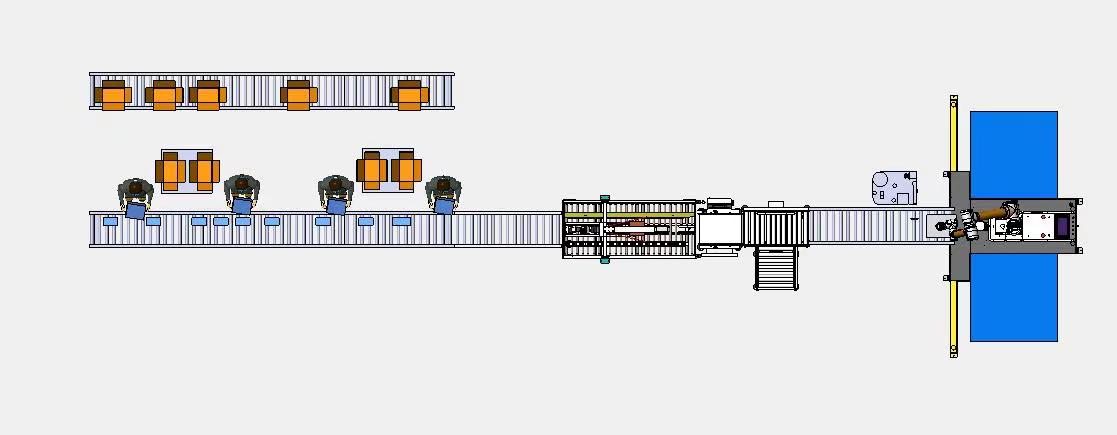

The automatic palletizing robot is applicable to chemical plants, pharmaceutical industry, grain crops, fertilizer, food, decorative building materials, beverages, metallurgical industry, fire-resistant and thermal insulation materials and other fields, and can be used for fully automatic packaging and palletizing of bags, whole boxes, barrels, cans and plates. The palletizing robot is one of the indispensable packaging equipment in today's production line. Its basic function is to stack equipment and carry goods normally.

As an indispensable part of the stacking robot, the working performance of the stacking manipulator includes high stability, compact and novel structure, small mass and other main parameters, which is of great significance to the overall working performance of the stacking robot.

According to different design products and different types of mechanical arms and claws, the palletizing robot has high efficiency, high cost performance, strong adaptability, low cost, and can perform palletizing well.

The palletizing robot can solve the problem of increasingly expensive labor costs. With the development of the times and the determination of the educational level of young people, many people are not easy to engage in single manual labor. Therefore, this kind of technical work of porters is likely to decline, and it is difficult to recruit people for enterprise development.