We believe that AI can help palletizing robots to complete high-risk tasks instead of humans

Stacking robot is a common automation equipment to improve the production efficiency of enterprises. In recent years, the aging problem of China's population is serious, and the development of manufacturing enterprises is faced with the problems of difficult recruitment and high cost of employment management. Therefore, more and more enterprises begin to turn their attention to robots, hoping to use industrial robots to solve the production problems of Chinese enterprises. It used to take more than ten people to complete the stacking work, but now only one stacking robot can complete it.

Market outlook 2022-10-06

In the field of industrial robots, what are the application scenarios of intelligent manufacturing a

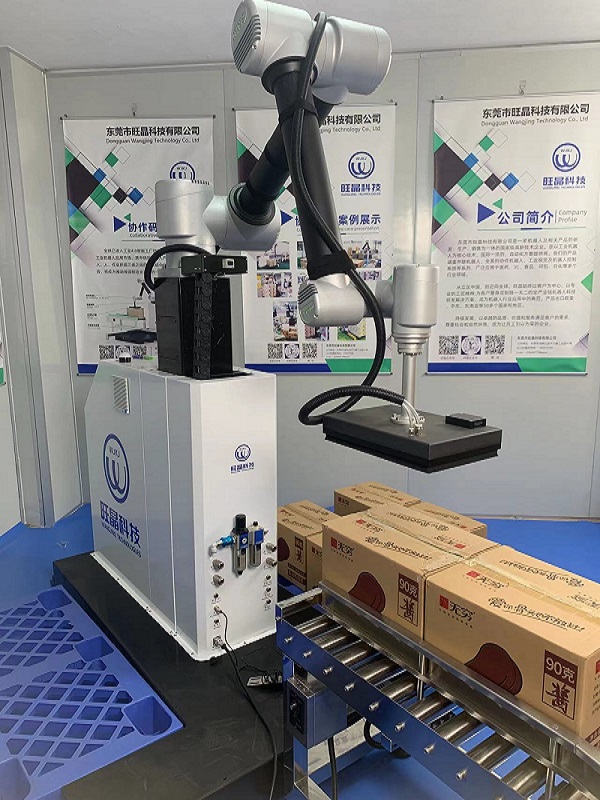

The important role of cooperative palletizing robot is to reduce the cost of manual logistics and facilitate the grabbing, handling and placing of goods.

People often find them in various express collection points, factories and other industrial scenes.

In recent years, with the cooperative mobile palletizing robot system becoming more efficient, fast and accurate software, cooperative mobile palletizing robot has been gradually applied in many companies.

Market outlook 2022-10-31

What are the specifications and standards of our carton opener for cartons

As we all know, in the product packaging design of enterprises, the use of the unpacking machine can further improve the production efficiency of the outer packaging process of enterprises, and is one of the indispensable mechanical equipment for mass production. Although the unpacking machine should be an automatic packaging mechanical equipment for unpacking cartons, many cartons on the market cannot use the unpacking machine at present. Therefore, there are relevant specifications and standards for cartons.

Market outlook 2022-11-03

With the continuous development of intelligence and informatization, the future development directio

The stacking manipulator has a material stacking sequence and arrangement setter, which simulates some action functions of the hand and arm. According to fixed procedures, it can automatically and neatly stack packaged goods of different sizes on pallets or production lines. Stacking manipulator can replace manual labor, realize mechanization and automation of production, operate in dangerous environment, and protect personal safety.

Market outlook 2022-09-23

Our palletizing robot has many advantages

The operation of the palletizing robot is very simple, just set the picking position and tray position, and then design the running track to place the operation robot. The stacking position adjustment is also very simple, and can be directly operated on the touch screen. If you want to change another product, just input the specifications of the new product into the system.

Market outlook 2022-09-23

This 3D destacking robot realizes hybrid destacking automation and can realize multiple processes

In recent years, a variety of warehouse automation machines and equipment have appeared in China. How to use automated machines to improve the efficiency of warehousing operations and reduce labor seems to be the concern of the warehousing industry at this stage. From process planning to software and hardware design, the specific conditions of the construction site should be fully considered. The invention can improve the limit under complex scenes and achieve efficient operation

Market outlook 2022-11-01

These problems are the key to the normal and stable operation of the automatic stacker

The capability of fully automatic palletizing can be easily demonstrated. Just put the weighed raw materials on the tray orderly according to the required sorting method. It only needs to be stacked neatly, not packed, not stacked upside down, indicating that the stacker meets the requirements. Naturally, in order to achieve this, the stacker must meet the preconditions of its own work, namely, switching power supply and pneumatic valve.

Market outlook 2022-10-12

With the development of Internet technology, Internet technology is also making continuous progress.

The birth of the palletizing robot has affected the traditional handling mode, freeing workers from high-intensity and monotonous operations.

Market outlook 2022-11-03