With the continuous development of intelligence and informatization, the future development directio

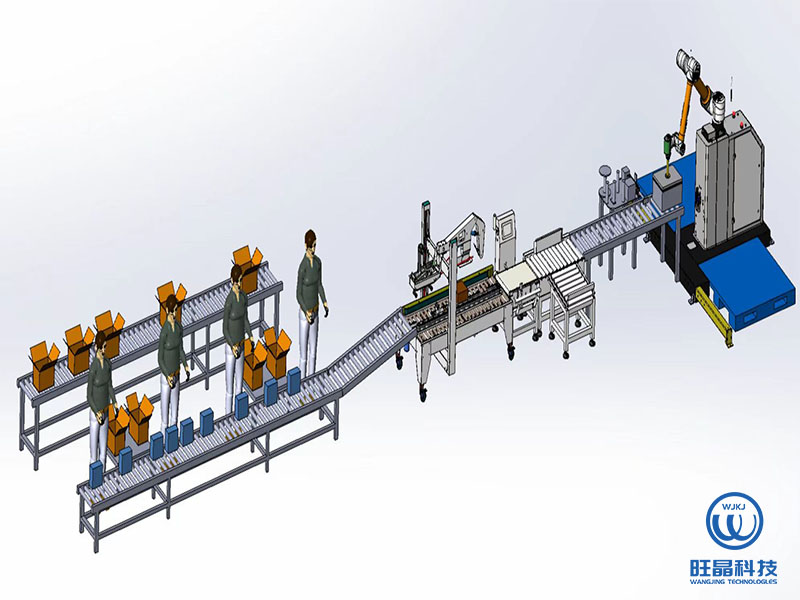

The stacking manipulator has a material stacking sequence and arrangement setter, which simulates some action functions of the hand and arm. According to fixed procedures, it can automatically and neatly stack packaged goods of different sizes on pallets or production lines. Stacking manipulator can replace manual labor, realize mechanization and automation of production, operate in dangerous environment, and protect personal safety.

Therefore, it is widely used in feed, flour, cement, starch, fertilizer, automobile, logistics, household appliances, medicine and other industries. Today we will discuss with you the future development direction of palletizing robot.

1. Improve automation

Stacking manipulator is the product of the combination of mechanical and electronic technology, and the automation part mainly depends on the development of computer technology. The development direction of modern industrial technology is automation, intelligence and unmanned. Therefore, the automation and intelligence of the stacking manipulator is an important indicator to measure whether the equipment of the stacking manipulator is advanced or not. The automation of the stacking manipulator is mainly embodied in two aspects: automatic control and automatic detection. The rapid improvement of the automation degree of the stacking robot mainly depends on the application of microelectronics, infrared, sensors and other technologies. The application of microcomputer in the stacking robot has greatly improved the efficiency and quality.

2. High speed stacking manipulator

On the basis of high-speed single machine, improve the overall high-speed operation of the stacking manipulator system. High speed stacking manipulator shall be based on the improvement of automation and optimization of manipulator structure, so as to improve the operation and production efficiency of the entire stacking system.

3. Diversified functions of stacking manipulator

With the continuous development of various products and small batch commodity markets, as well as the increase of small and medium-sized users, the utilization rate of palletizing robots that can only be used for fixed batches and fixed sizes is greatly reduced. Therefore, palletizing robots are gradually developing and innovating in the direction that they can be applied to various environments and commodities.

With the progress of science and technology, automation technology is also constantly developing and updating. The main development direction of future stacking manipulator is to improve automation, stacking efficiency and function diversification.