So why are palletizing robots so popular?

With the emergence of palletizing robots, palletizing robots are widely used in various industries. Do you know why palletizing robots are so popular?

The following is a detailed introduction.

With the accelerated development of industry, intelligent devices represented by industrial robots are facing unprecedented development opportunities. For many years, China has been the main consumer market of intelligent robots.

In the industrial manufacturing industry, there is a lot of room for the robot industry to transform and upgrade to intelligence. For a long time to come, the robot industry will be very prosperous.

Why are palletizing robots so popular?

With the continuous progress of technology, the application scope of palletizing robot is also expanding and has been applied to various fields, bringing convenience to many production enterprises. More and more people have a deeper understanding of it and realize the benefits of palletizing robot, so this product is more and more popular and loved by people.

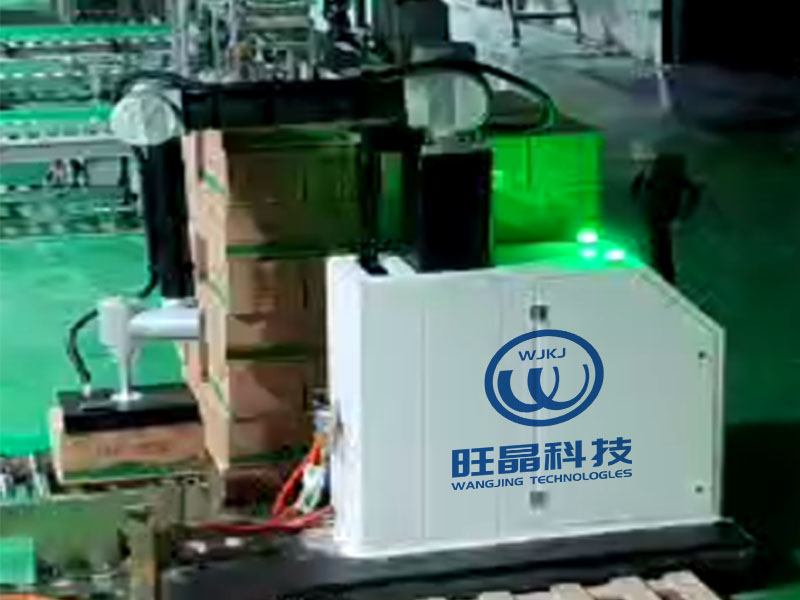

Stacking robot is a high-tech product of mechatronics. Medium and low grade stackers can meet the production demand of medium and low output, while automatic stackers are more suitable for batch production.

The automatic stacker can stack bags, plastic blocks, boxes and other products. Optimize the design according to the required grouping mode and number of layers to make the stacking shape compact and neat.

Stacking robot can greatly reduce the number of workers and labor intensity. It is a high-tech product developed in modern industrial society, which is of great significance to improve productivity and reduce costs.