The market scale of industrial robots in China has reached 17.3 trillion yuan, and stacking robots h

The disadvantages of manual palletizing of cooperative palletizing robot are pointed out: the palletizing form is irregular, the palletizing is often reversed, and there are potential safety hazards. In the loading process, due to the irregular stacking form, the loading capacity is low and the transportation cost is high. Low stacking efficiency and high labor cost.

Market outlook 2022-09-21

In this way, automatic packing can meet the needs of various enterprises.

In the automatic packaging machine, it is the core of the entire packaging line system. Although packaging machinery is not a machine for directly producing products, it is necessary for production activities.

Market outlook 2022-11-08

How to realize the role of this technology in automated production lines?

With the development of automation technology, people pay more and more attention to the automatic and efficient production mode.

Market outlook 2022-09-22

At present, what functions does the intelligent robot stacker have?

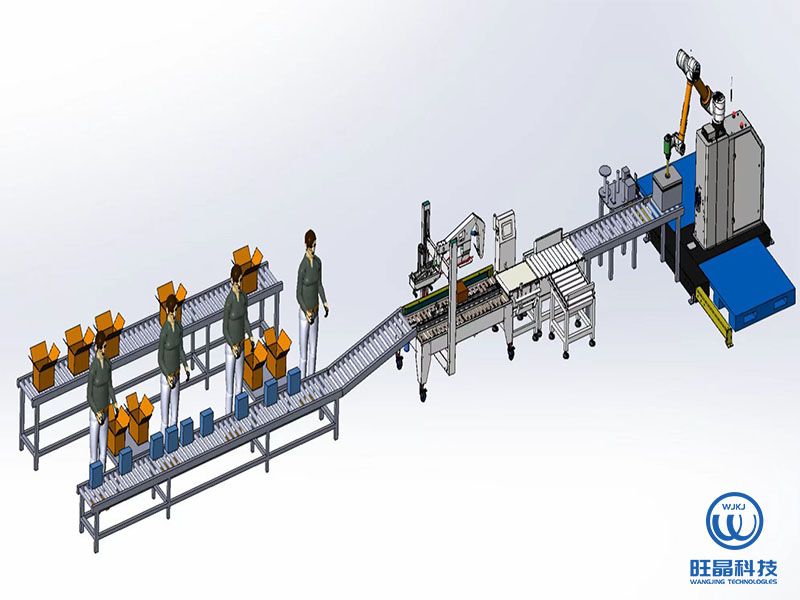

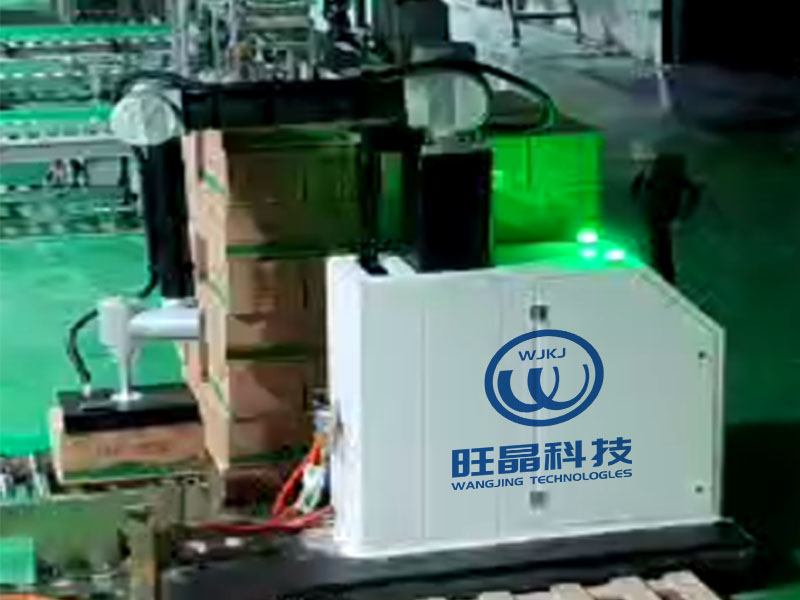

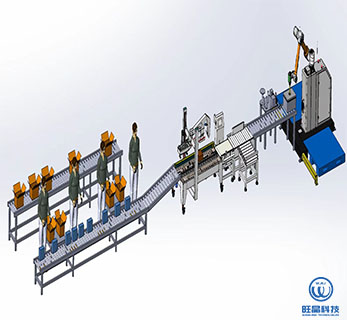

Robot palletizing opportunities greatly reduce human capital and labor efficiency. The stacker is used to automatically stack the packaging bags, cartons or other packaging products sent by the belt conveyor according to the working mode of the customer's process standards, and then transport the stacked raw materials to the designated location through the electric forklift mechanical equipment.

Market outlook 2022-10-27

Characteristics of cooperative palletizing robot

Cooperative palletizing robot has brought fundamental changes to the future industrial production and factory manufacturing, and cooperative palletizing robot has decisive and important advantages

Market outlook 2022-09-18

What is the basis for the normal and stable operation of our automatic stacker

Collaborative mobile has fully played the role of many industries to improve the whole process. Packaging robots are generally used for light practical operations to put objects or services into small boxes or pallets. The software of the cooperative stacking robot system has a compact and streamlined design, which can provide the stacking of small precision and speed boxes, water bottles, packaging bags, trays and cartons from medium to large payloads to super heavy payloads.

Market outlook 2022-10-27

How to optimize the workflow and how to use these cooperative mobile palletizing robots

Collaboration brings into full play the role of many industries to improve the whole process. Packaging robots are generally used for light practical operations to put objects or services into small boxes or pallets. The software of the cooperative stacking robot system has a compact and streamlined design, which can provide the stacking of small precision and speed boxes, water bottles, packaging bags, trays and cartons from medium to large payloads to super heavy payloads

Market outlook 2022-10-12

Correct operation method of automatic production line

In the period of continuous development of modern science and technology, automated production has entered most of the sales markets, and manual production and manufacturing has gradually been replaced by automated assembly lines of artificial intelligence technology. Now, I would like to introduce the appropriate operating steps of belt transportation production lines in automated assembly lines.

Market outlook 2022-09-20