Market pattern analysis, artificial intelligence technology development and application of cooperati

Cooperative robot is an important branch of industrial robot. The cooperative robot is mainly lightweight, and its structure is relatively simple, so the whole robot lacks rigidity. Therefore, the load of cooperative robot is generally lower than that of traditional industrial robot, and its working range is only similar to that of human arm. The application of cooperative robot products meets the requirements of precision assembly, inspection and man-machine joint operation. At present, 3C has realized the application of semiconductors in the automotive medical field, involving complex processes such as welding, assembly, grinding and testing in the production of electronic products. Analysis of market scale trend of cooperative robots?

1. Is to cooperate with people and give full play to the advantages of people and robots

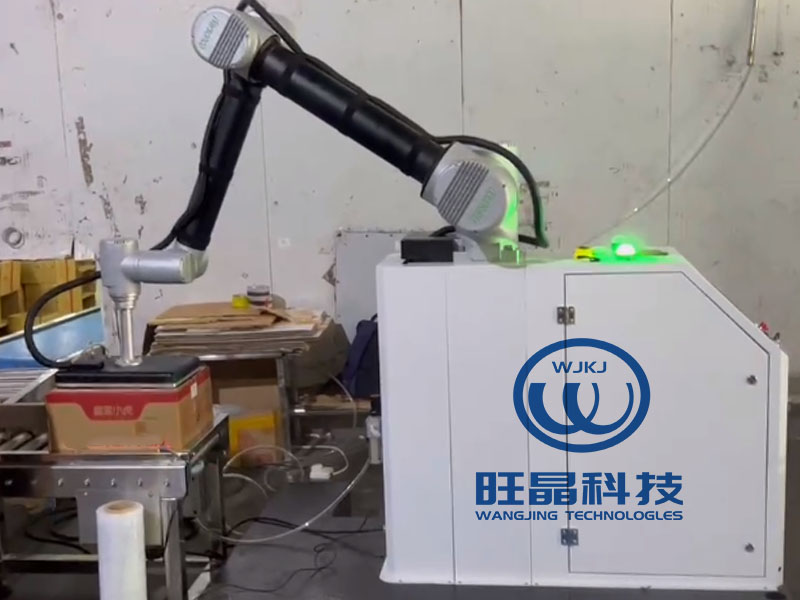

According to the 2020-2024 China Cooperative Robot Industry Deep Research and Investment Prospect Forecast Report issued by the China Investment Industry Research Institute, compared with industrial robots that have been developed for decades, the biggest breakthrough of cooperative robots is that they can directly cooperate with humans, without the need for isolation with a security fence. This method not only shortens the distance between humans and robots, but also greatly reduces the space station area. More importantly, it can fully combine the advantages of people and machines, learn from each other, and let robots help people complete those highly repetitive and high-precision tasks, while humans solve the problems of high flexibility and optimization. When assembling high-precision heavy parts, man-machine cooperation highlights the advantages of man-machine integration.

2. High security

High security is one of the basic characteristics of cooperative robots, which aims to provide security for human-computer interaction at the beginning of design. Therefore, in order to achieve the safety of human-computer cooperation, cooperative robots generally adopt lightweight design, such as lightweight body shape and internal skeleton design methods. Limiting running speed and motor power; This is a way to fundamentally avoid injury, such as joint torque sensor and safety controller technology for contact detection.

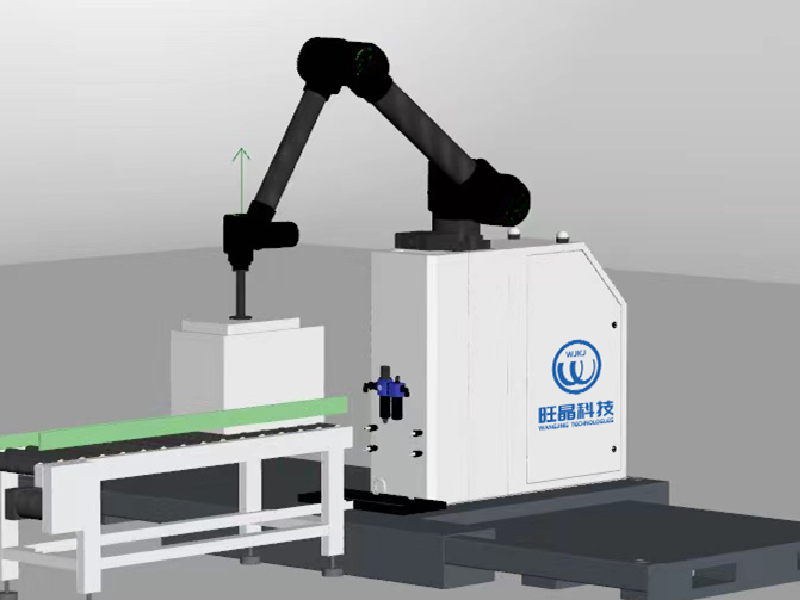

3. Simple, flexible, and easy to use deployment

Cooperative robots generally support drag teaching, and are equipped with intuitive user programming interfaces, simple integrated operations, easy to master software systems, modular encoders, etc. In most places, ordinary workers can complete a lot of deployment work through certain training, so deployment is very simple.

In addition, the optical collaboration robot can be installed on the desktop or device, which is very flexible.

4. Low cost

Industrial costs usually include the price and deployment of the robot itself. The price of cooperative robots is generally 10-20w. Because it is easy to program and install, deployment costs are usually low. In addition, the space requirements of light collaborative robots are greatly reduced, which can reduce a lot of installation and factory costs for enterprises.

According to different load capacities, the price range of industrial robots used in mainstream occasions is 10w-40w yuan, and the deployment cost is high, at least 2-3 times of the robot price.

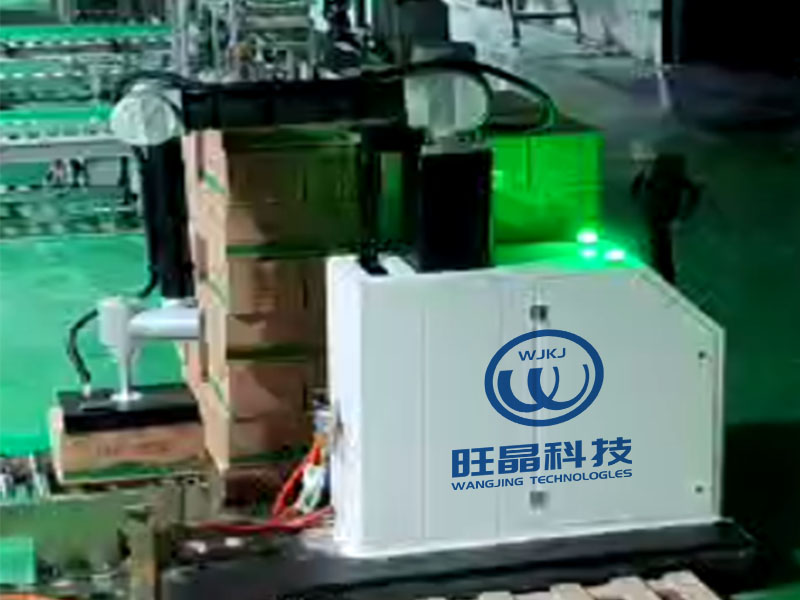

5. Support flexible production mode

Robot cooperation breaks through the limit of safety barrier and is not limited by fixed geographical location. On the contrary, it can quickly adapt to new off-site production tasks according to actual needs, and only requires simple programming and training, so as to better support the flexible production mode. Even if the robot breaks down, new robots can be quickly added.

summary

What is the scale trend of the collaborative robot market? Therefore, the prelude of the second half of the cooperative robot is slowly opening. GGII judges that in the future, the forms of cooperative robot products will be more abundant, the concept will be weakened, and the landing and application will be strengthened; The competition between manufacturers is no longer a single price competition, but more reflected in the comprehensive strength of technology, products, channels, funds, talents, management, strategy, etc. Downstream customers' recognition of collaborative robots has been greatly improved, and hundreds of large orders have appeared frequently in the industry.