At present, what functions does the intelligent robot stacker have?

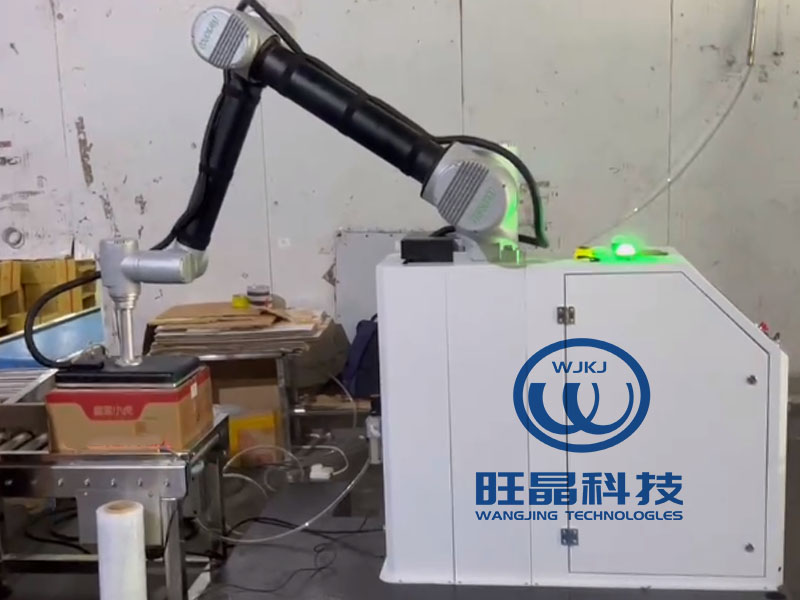

Robot palletizing opportunities greatly reduce human capital and labor efficiency. The stacker is used to automatically stack the packaging bags, cartons or other packaging products sent by the belt conveyor according to the working mode of the customer's process standards, and then transport the stacked raw materials to the designated location through the electric forklift mechanical equipment.

Most robotic palletizers will assist the pallet warehouse, and the removal and replacement of pallets do not require manual control. After palletizing, the electric forklift will remove the pallet, and then the pallet warehouse will transport a new pallet to the designated location. In order to ensure the stability of production, safety barriers are usually installed around the automatic stacker. When the stacker is working, personnel are not allowed to enter the working range of the stacker.

1. Today's robots have strong professional ability. Robot stackers have many functions, such as packaging, transportation, welding, stacking, etc. Robot stacker is mainly used in the warehouse of freight logistics companies or large companies, and has been trusted by more and more companies.

2. Stacker is a new technology industrial automation production line equipment. The birth of robot is an important branch of industrial robot. Its characteristic is that various daily tasks can be estimated through programming. It takes into account the characteristics of people and equipment in terms of structure and function, especially in terms of display convenience and applicability, and has broad market potential in China. According to the structural and technical data of the robot stacker, pallets of different shapes can also be customized as required, and the pallets can also rotate.

3. It can be extended to robot stacker to realize various functions. Automatic loading and unloading. Robot stacker is an automatic equipment that can crawl, carry and work according to the specified program flow, motion track and requirements. Especially in harsh environments and complex, simple and frequent operations, it can improve the productivity and uniformity of new products and save labor costs.

4. Users can prepare robot palletizers according to different product categories and requirements, so as to improve the production efficiency of palletizing. Improve production, quality and efficiency for enterprise development. All production lines are automated and intelligent. We should deal with the problem that it is difficult to recruit people for enterprise development.