The control technologies of the stacking robot based on artificial intelligence include

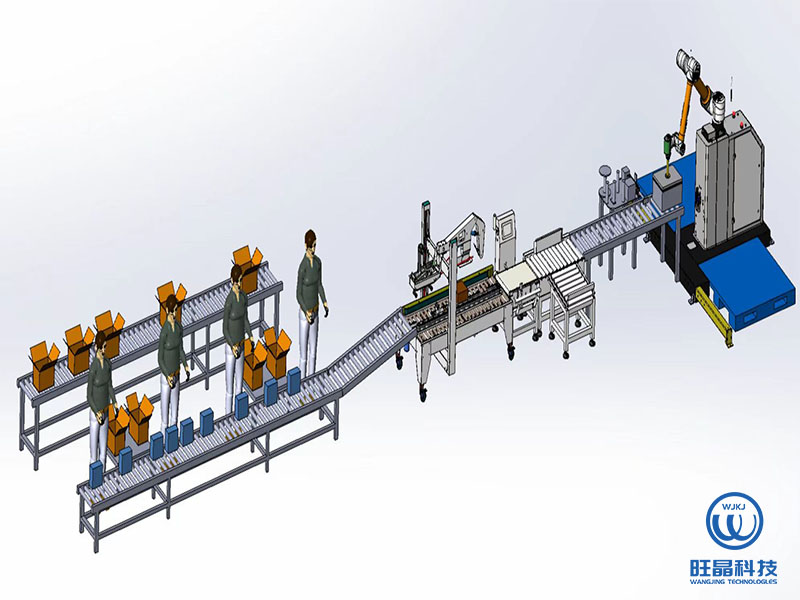

Compared with ordinary mechanical palletizer, the palletizing robot has the advantages of high efficiency, low failure rate and convenient maintenance, so it is widely used. The main task of palletizing robot control technology is to control the movement position, posture and trajectory, operation sequence and action time of industrial robot in the workspace. Now let's talk about the control technology of the stacking robot.

1. Networked robot control technology

At present, the application engineering of palletizing robot has developed from a single robot workstation to a robot production line, and the network technology of robot controller is becoming more and more important. The controller has the networking function of serial port, field bus and Ethernet.

2. Fault diagnosis and safety maintenance technology of stacking robot.

It is the key technology to ensure the safety of robot to diagnose and maintain the faults of robot through various information.

3. Modular hierarchical controller software system.

The software is built on Linux, a real-time multitask operating system based on open source, and adopts hierarchical and modular structure design to realize the openness of the software system. The whole controller software system is divided into hardware driver layer, core layer and application layer.

4. Open modular control system architecture of stacking robot.

Distributed CPU computer structure is adopted, which is divided into robot controller (RC), motion controller (MC), photoelectric isolation I/O control board, sensor processing board and programming teaching box. The robot controller (RC) communicates with the programming teaching box through the serial port/CAN bus.

The application of palletizing robot has formed a good market in China and has been recognized by most customers. In fact, the main task of the stacker control system is to control the spatial motion position, trajectory and posture of the robot in the working process. In addition to the control technology of the stacking robot, the design of the control system of the decoding stacker is also required. Only in this way can we better understand the palletizing robot.