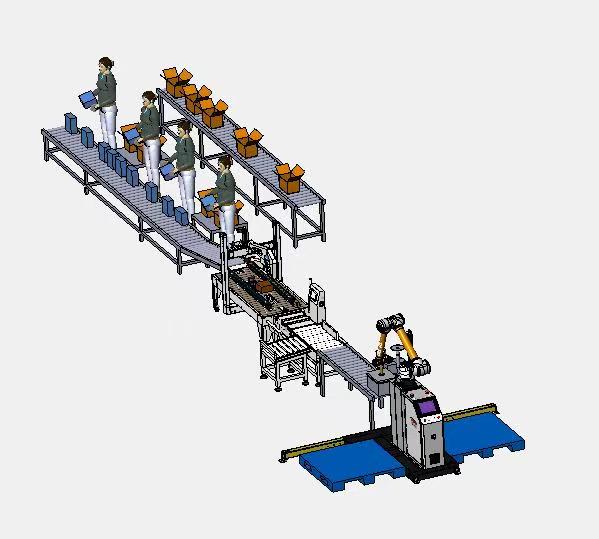

At present, the company has formed a whole industrial chain automatic production line process layout

The advantages of the automatic production line are very obvious, but if the overall planning of the initial overall processing process layout is not good, the advantages of the automatic production line will be discounted. The automatic production line process layout is generally divided into linear layout, zigzag layout, and T-shaped layout,I think that the process layout of the automatic production line needs to be prepared as follows

1. In the automatic production line, it is necessary to do a good job in the layout of the processing technology, to do a good job in investigation and study, to collect the information data of the automatic production line stations with scientific methods, to use the collected information to make the layout of the processing technology, to make a reasonable layout of the stations in the automatic production line through effective and efficient analysis of the information, and to pay attention to the overall perspective, and to attach great importance to the unification, standardization, systematization Rationalization.

2. In terms of the phenomenon of processing process layout, it is also necessary to consider the wiring method of the wire controller, switching power circuit and other factors. The wiring of the wire controller is important to conduct the wiring on the land surface and in the air. Under the premise of the actual wiring, the experienced staff must take into account the factors such as control lines and trunking, try to avoid the harm of Internet resources, control costs, and attach great importance to improving efficiency.

3. When designing the control scheme, pay attention to the factors such as lifting and rotating of the station. In the automatic production line, when designing the pneumatic circuit design diagram, the operation form of the operating platform should be used. Fully consider that if the system stops due to the interaction force or other factors under the control of the pneumatic control valve, the treatment must be given by adding the control overflow valve to avoid more difficulties, Prevent the occurrence of adverse effects that the enterprise cannot bear, and reduce the adverse effects of the enterprise.

4. When analyzing the circuit design drawing, attention should be paid to the factors such as lifting and rotation of the station. In the automatic production line, when designing the pneumatic circuit design drawing, the operation form of the working platform should be used. Under the control of the control valve, if the system stops due to the interaction force or other factors, the solution given is to add the control overflow valve, This kind of method can avoid the situation that is difficult to control and make the automatic production line run normally, reliably and stably.