At present, the main application scope of domestic stacking manipulator is as follows

Among all the stacking equipment, the automatic stacking manipulator is a fully functional equipment. Stacking manipulator can completely replace manual work, and is widely used in dozens of industries such as feed, fertilizer, flour, cement, etc. Stacking manipulator can be used to carry goods and load and unload goods, and can even completely replace people to complete high-precision work. It can be said that these automatic equipment are essential for enterprise production and logistics transportation.

Main application scope of stacking manipulator:

1. Conditions for the carriage of goods. In order to adapt to the work of the stacker, the articles to be transported shall be packed in boxes and bags. In this way, the stacker can carry the goods onto the conveyor. In addition, manually loaded goods shall not be replaced after parking.

2. The shape of the object to be carried. One of the working conditions of the stacker is that the shape of the goods to be handled should be regular to facilitate packing. Cylinders, cans, rods, tubes and rings made of glass, iron, aluminum and other materials are not convenient for packaging due to their irregular shapes. The articles suitable for the operation of the stacker include cartons, wooden cases, paper bags, gunny bags and cloth bags.

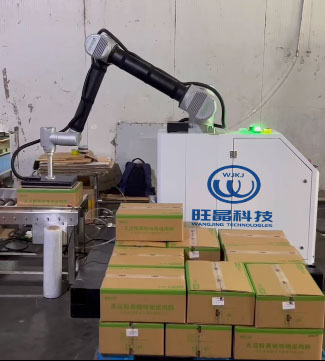

The automatic stacking manipulator is an information integration system on the enterprise production line, including the industrial stacking manipulator body, controller, programmer, robot gripper, pallet conveying positioning technology equipment and stacking mode software. They are connected with the production control system to form a complete integrated production line. The equipment can replace manual work continuously and stably for 24 hours. There is no human involvement in the work process. To some extent, this is an unmanned factory. Automatic palletizing manipulator automatic handling and palletizing workstation can be used in feed, fertilizer, flour, cement, starch and other industries.

With the rapid development of intelligent automation technology, palletizing manipulators with various functional characteristics continue to emerge. With its powerful functional advantages, the automatic stacker has won the market and the trust and praise of users. Since the advent of various stackers with different functions, they have gradually replaced the traditional manual operation. The use of these intelligent devices not only greatly improves the production efficiency of enterprises, but also increases the benefits of enterprises!