Reasons why enterprises choose palletizing robots to replace traditional production lines

The continuous increase of labor costs has formed a development trend, and it is difficult for manufacturing enterprises to recruit people. In the face of difficulties, many enterprises are moving towards automation technology production lines. Among them, the automatic technology complete equipment production line of palletizing robot is more popular and has developed rapidly in recent years.

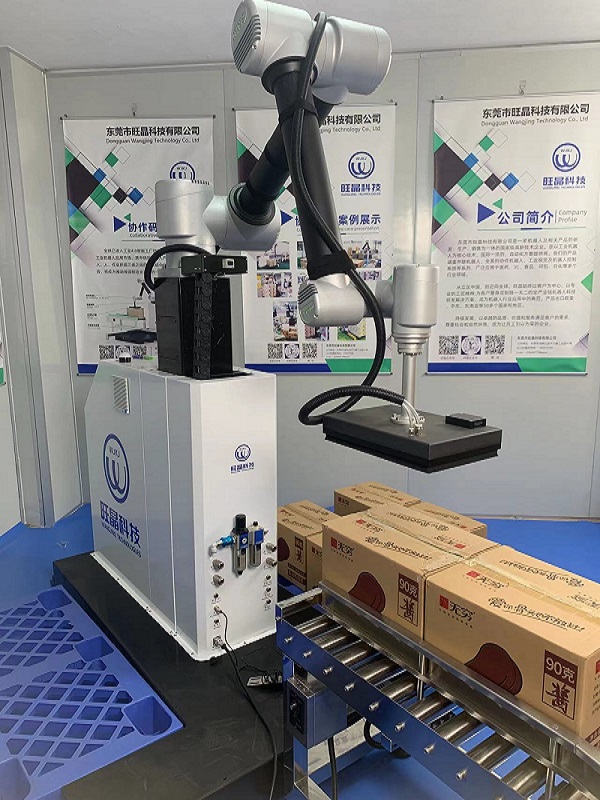

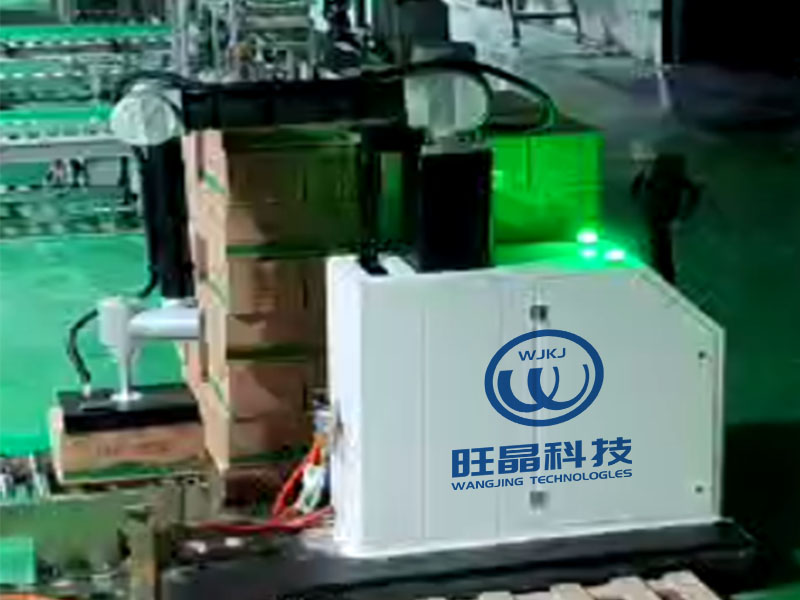

From the domestic market, the continuous increase of labor costs has formed a development trend, and it is difficult for manufacturing enterprises to recruit. In the face of difficulties, many enterprises are moving towards automated technology production lines, among which automated technology complete equipment production lines of cooperative palletizing robots are more popular and have developed rapidly in recent years. What are the obvious advantages of palletizing robot?

1. Strong scope of application: When the size, volume, appearance and pallet size of the products produced by the enterprise change, only minor changes are required on the touch screen, which will not affect the normal manufacturing of the enterprise. However, the replacement of the traditional pedal stacker is very troublesome, even impossible.

2. High reliability: the repetitive operation of the cooperative palletizing robot can keep the same situation all the time without the subjective influence of the same kind of people, so its control stability is high.

3. High technical level: the operation of the palletizing robot is controlled by the system, without manual participation. The technical level is high, saving a lot of human capital.

4. Good precision: the operation and control of the stacking robot are accurate, and the position error is basically below the mm level, so the precision is very good.

5. Low energy consumption: The output power of the pedal stacker is about 26KW, and the output power of the stacker robot is about 5KW, reducing the use cost of customers.

6. Wide application range: cooperative palletizing robot has a wide range of applications. It can complete climbing, transportation, loading and unloading, stacking and other operations.

7. High efficiency: the palletizing robot works faster without time interruption, so it is highly efficient.

8. Less total floor space: The stacker can be used when it is located in a narrow indoor space, which is conducive to the layout of the production line in the customer's industrial plant and can free up a larger total warehouse area.

The cooperative palletizing robot has improved the manufacturing efficiency, product quality, usage and workload of workers, and economic benefits of enterprises, which is the main reason why enterprises choose palletizing robots to replace traditional production lines.