Can we grasp the large demand for the application of cooperative robots in business scenarios?

From B to C, the market prospect is broad.

Cooperative robots, from B to C, have broad market prospects. Finally, to a large extent, the application stage of intelligent cooperative robots is still based on the B-end industry market.

Man machine cooperation is the general trend.

With the development and maturity of artificial intelligence, robots will become more and more intelligent, assume more responsibilities in many fields, and become important assistants and tools for human beings. Humans and robots will be interdependent, but this is a long-term gradual process.

The Internet is mainly to solve the problem of connection, including the connection between people, people and information

The next era, that is, the era of artificial intelligence, is mainly to solve the processing problems after connection and information processing

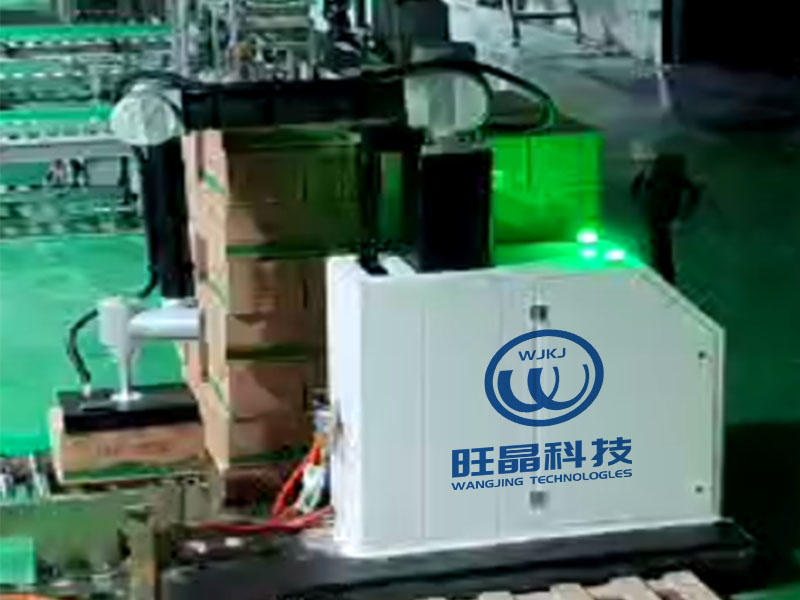

Man machine cooperation is the inevitable choice of robot evolution and the general trend. It is characterized by safety, ease of use, low cost, and ordinary workers can operate like electrical appliances.

Advantages:

1. Maximum flexibility in the production process.

2. Reduce the risk of injury and infection (for example, use special human-computer cooperative gripper)

3. Complete the repeatable process with high quality.

4. Built in sensing system is adopted to improve productivity and equipment complexity.

In the man-machine cooperation mode, robots are human assistants, helping people to do hard work (such as handling, loading and unloading, etc.) A major feature of human-computer cooperation is the absence of isolation and guardrails.

Although there are still many challenges for development, we believe that human-computer cooperation will be the general trend.