Market pattern analysis, artificial intelligence technology development and application of cooperati

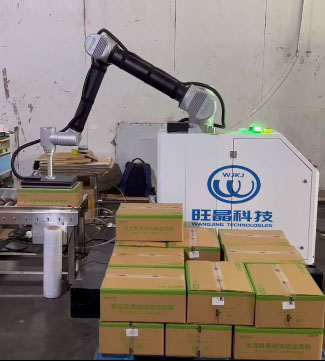

Cooperative robot is an important branch of industrial robot. The cooperative robot is mainly lightweight, and its structure is relatively simple, so the whole robot lacks rigidity. Therefore, the load of cooperative robot is generally lower than that of traditional industrial robot, and its working range is only similar to that of human arm. The application of cooperative robot products meets the requirements of precision assembly, inspection and man-machine joint operation.

Market outlook 2022-10-07

Stacking robot slowly replaces manpower

The palletizing robot presents a diversified development trend. It can replace the staff working in dangerous, continuous high temperature, toxic and harmful substances and other harsh environments, while ensuring product quality and improving work efficiency

Market outlook 2022-09-18

At present, what functions does the intelligent robot stacker have?

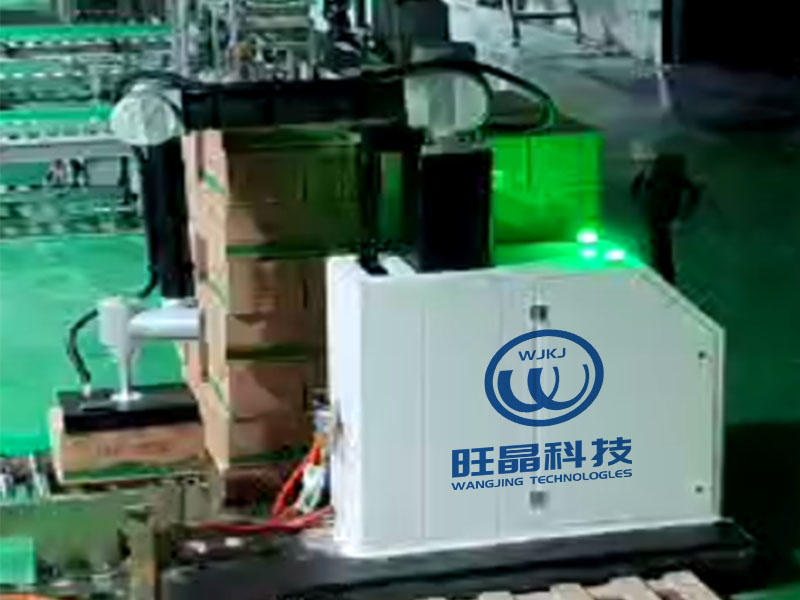

Robot palletizing opportunities greatly reduce human capital and labor efficiency. The stacker is used to automatically stack the packaging bags, cartons or other packaging products sent by the belt conveyor according to the working mode of the customer's process standards, and then transport the stacked raw materials to the designated location through the electric forklift mechanical equipment.

Market outlook 2022-10-27

Equipment Performance and Selection of Cooperative Stacking Robot

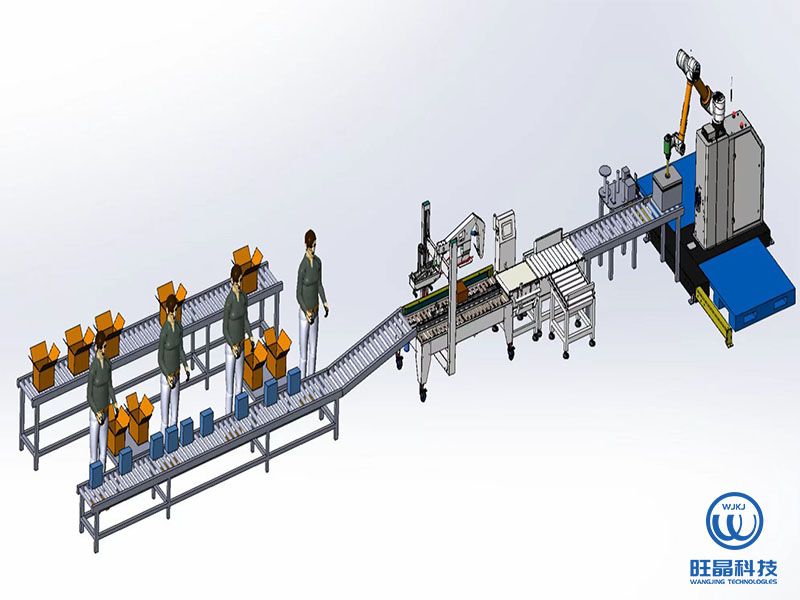

Because manual handling and palletizing cannot meet the needs of industrial production, the R&D and production of full-automatic and full-automatic handling and palletizing machines continue to accelerate. The structure of the fully automatic handling and palletizing machine is mainly composed of the power distribution cabinet, the main stacking behavior, the bag shaping and beautification, the bag body transmission, the pallet collection, the filling, handling and palletizing.

Market outlook 2022-09-20

With the rapid development of intelligent manufacturing, palletizing robot has become the mainstream

With the increasing popularity of automatic robot production, the cost of robots is also decreasing. In the past 30 years, the average price of robots has actually dropped by half, even exceeding the labor cost.

Market outlook 2022-10-06

Equipment characteristics of palletizing robot production line

It is applicable to the palletizing robot production line, chemical plants, pharmaceutical industry, grain crops, fertilizer, food, decorative building materials, beverages, metallurgical industry, refractory insulation materials and other fields, and can be used for fully automatic packaging and palletizing of bags, whole boxes, barrels, cans, and boards. The palletizing robot production line is one of the indispensable packaging equipment in today's production line. Its basic function is to stack products and package and transport them normally.

Market outlook 2022-09-19

In this case, we can solve this problem by using the full automatic stacker.

Now, more and more enterprises use automatic stackers. It is worth noting that there are many skills to understand and master in the process of using automatic stackers.

Market outlook 2022-09-23

Correct operation method of automatic production line

In the period of continuous development of modern science and technology, automated production has entered most of the sales markets, and manual production and manufacturing has gradually been replaced by automated assembly lines of artificial intelligence technology. Now, I would like to introduce the appropriate operating steps of belt transportation production lines in automated assembly lines.

Market outlook 2022-09-20