These problems are the key to the normal and stable operation of the automatic stacker

The capability of fully automatic palletizing can be easily demonstrated. Just put the weighed raw materials on the tray orderly according to the required sorting method. It only needs to be stacked neatly, not packed, not stacked upside down, indicating that the stacker meets the requirements. Naturally, in order to achieve this, the stacker must meet the preconditions of its own work, namely, switching power supply and pneumatic valve.

Market outlook 2022-10-12

Collaborative robots guide future factory changes! Compared with traditional industrial robots, it h

The future intelligent factory is created by the harmonious coexistence of people and machines. It requires robots to cooperate with humans and complete different tasks with humans. This includes not only the traditional tasks of "people can't do it, people don't want to do it, and people can't do it well", but also complex tasks that can reduce human labor intensity and improve the quality of human life

Market outlook 2022-09-18

With the development of automatic stackers, automatic stackers are used more and more widely, and mo

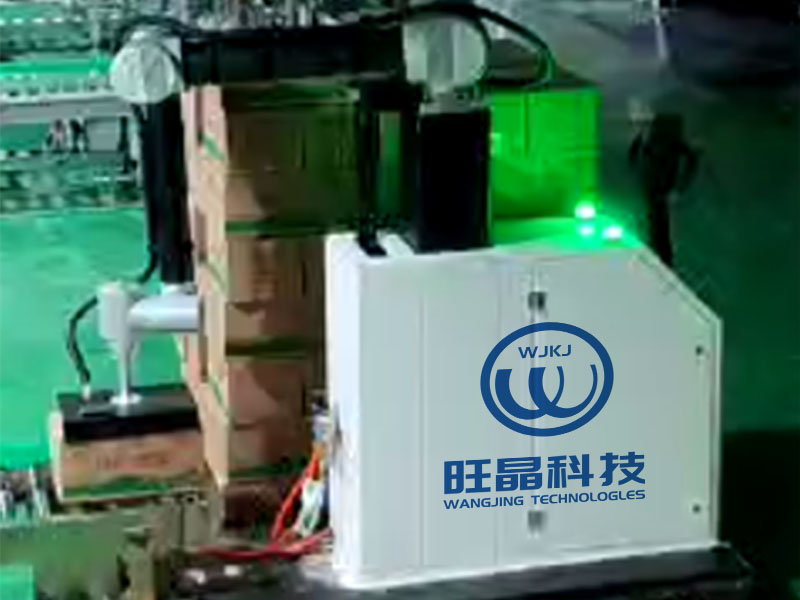

The labor intensity of manual stacking is high, and the turnover rate of post labor is high, which has a serious impact on production management. With the development of science and technology, the appearance of automatic stacker saves time and energy for product stacking, and can better help enterprises to complete transportation tasks.

Market outlook 2022-09-29

At present, what are the factors we need to consider in selecting industrial cooperative robots? How

For an old bird in the automation industry, a senior mechanic, and an electrician, selecting a suitable "robot" may be a simple task. But for those designers or factories who are ready to purchase and import robots for the first time, there may be some confusion.

Market outlook 2022-10-08

So, what is the significance of this technology's automatic palletizer?

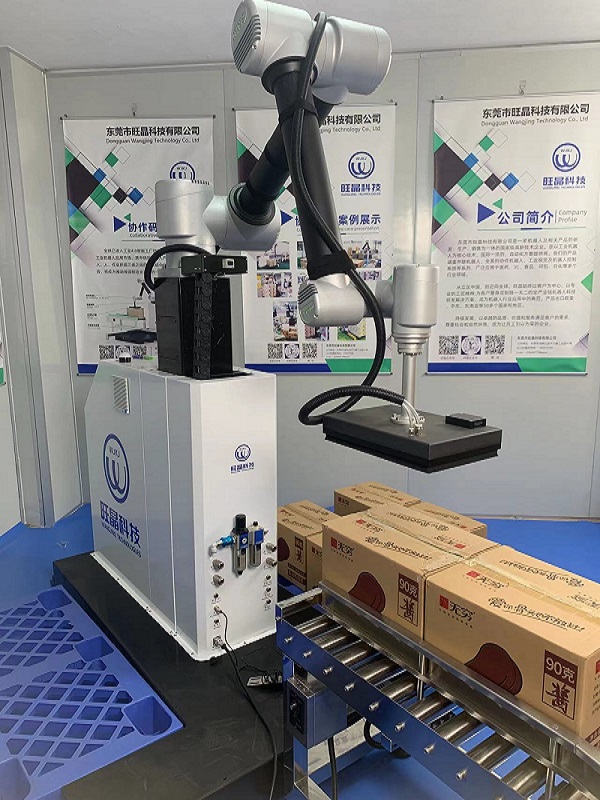

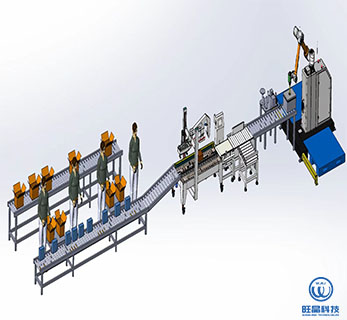

Automatic stacker is an industrial machine which has been widely used in recent years. It consists of three parts: chassis, stacker main body and conveyor. The position of the equipment can be adjusted freely according to the user's site conditions, from the initial step of the product to the offline. The appearance of automatic stacker represents a great progress in industrial automation, and also provides a great opportunity for social development and labor liberation. As an important auxiliary equipment for industrial assembly line production, its existence can reduce the total number of workers needed on the assembly line and improve industrial efficiency.

Market outlook 2022-09-22

At present, the main application scope of domestic stacking manipulator is as follows

Among all the stacking equipment, the automatic stacking manipulator is a fully functional equipment. Stacking manipulator can completely replace manual work, and is widely used in dozens of industries such as feed, fertilizer, flour, cement, etc. Stacking manipulator can be used to carry goods and load and unload goods, and can even completely replace people to complete high-precision work. It can be said that these automatic equipment are essential for enterprise production and logistics transportation.

Market outlook 2022-09-23

We are now studying the problems faced by palletizing robots

Stacking robot is a kind of industrial robot, which is widely used at present. With the decline of labor rate and the rise of labor cost, palletizing robots are used more and more. Stackers and porters are manufactured in manufacturing enterprises to replace manual post packaging operations.

Market outlook 2022-09-28

What are the benefits of using the fully automatic stacker

With the emergence of automatic stackers, stackers are more and more widely used in our lives. Do you know the advantages of using automatic stackers?

Market outlook 2022-09-29