What is the basis for the normal and stable operation of our automatic stacker

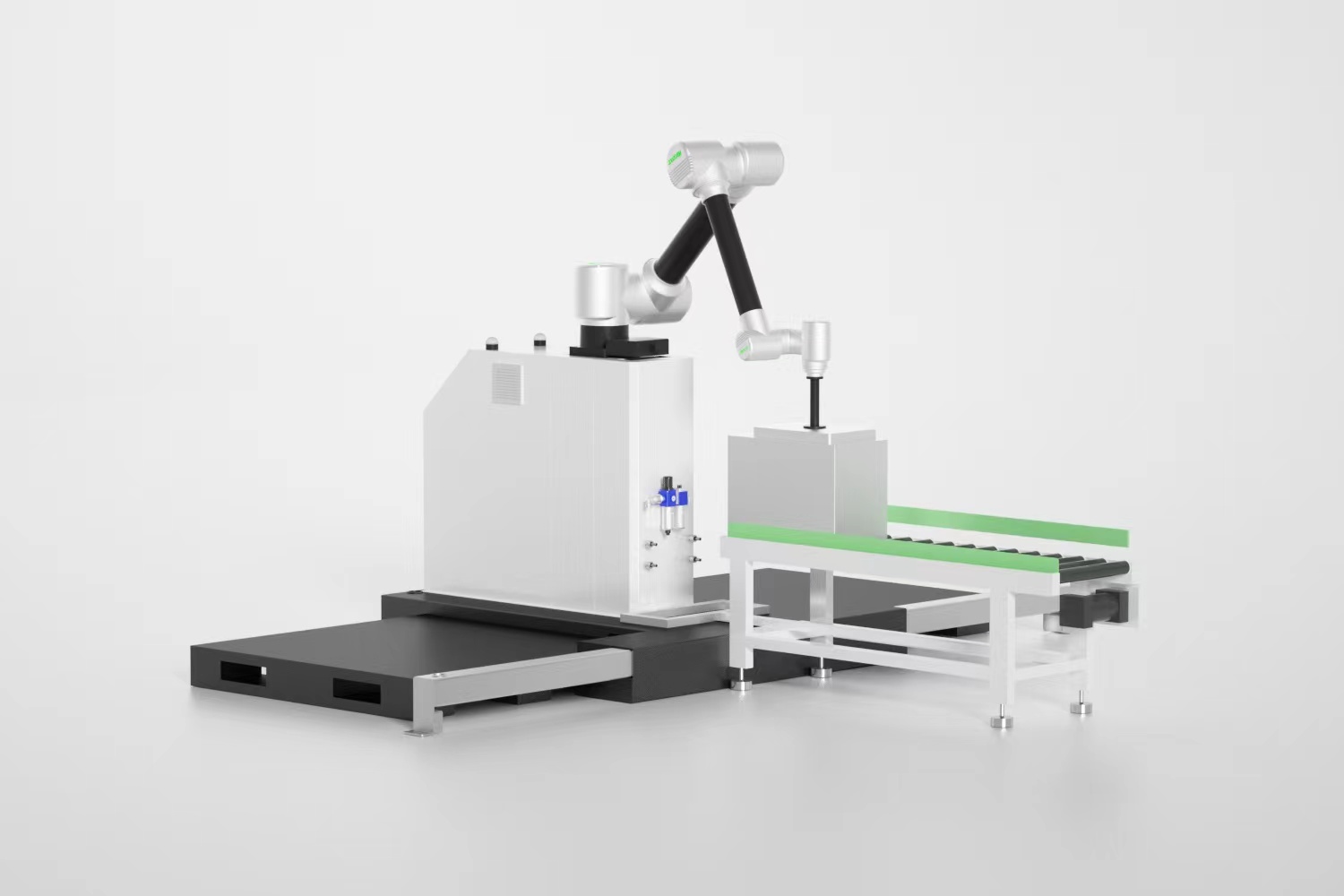

Collaborative mobile has fully played the role of many industries to improve the whole process. Packaging robots are generally used for light practical operations to put objects or services into small boxes or pallets. The software of the cooperative stacking robot system has a compact and streamlined design, which can provide the stacking of small precision and speed boxes, water bottles, packaging bags, trays and cartons from medium to large payloads to super heavy payloads.

Market outlook 2022-10-27

The robot adopts a fully automatic palletizing robot, automatic palletizing, automatic assembly line

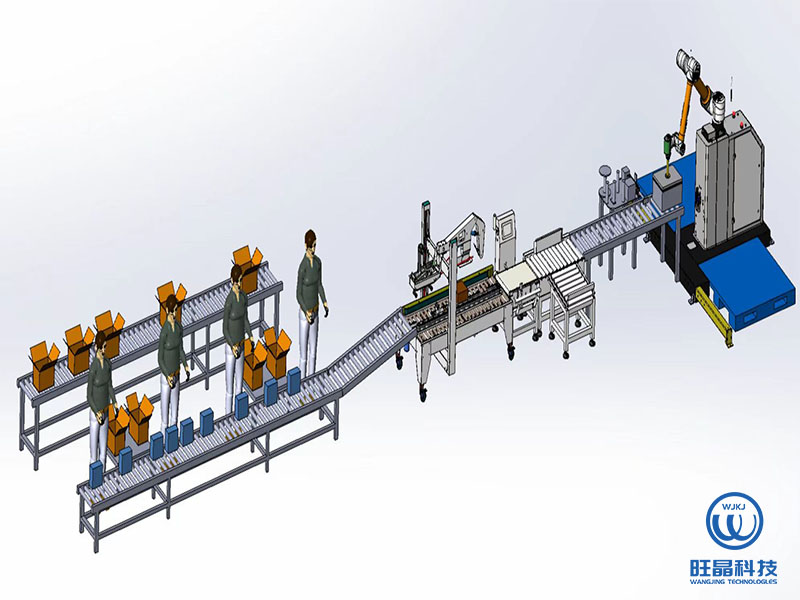

With the development of science and technology and the shortage of labor force, many factories and workshops choose unmanned full-automatic palletizer robot for automatic palletizing, which not only saves costs, but also improves production efficiency. The automatic palletizing robot usually palletizes the bags, boxes, barrels and other materials on the production line to the hauling line according to the instructions set at the end of the production line. Finally, it is stored in the warehouse with a forklift.

Market outlook 2022-09-29

With the development of Internet technology, Internet technology is also making continuous progress.

The birth of the palletizing robot has affected the traditional handling mode, freeing workers from high-intensity and monotonous operations.

Market outlook 2022-11-03

In this process, we should not only consider the characteristics of the automated production line, b

Automatic production line refers to the production line that connects the machines on the production line according to the technological process to realize automatic control, automatic measurement and automatic continuous production, including the whole p

Market outlook 2022-11-08

Robot is one of the important characteristics of palletizing robot in intelligent manufacturing

Stacking robot Mechatronic high-tech products can complete the high automation of the system and provide necessary maintenance for equipment and operators.

Market outlook 2022-09-23

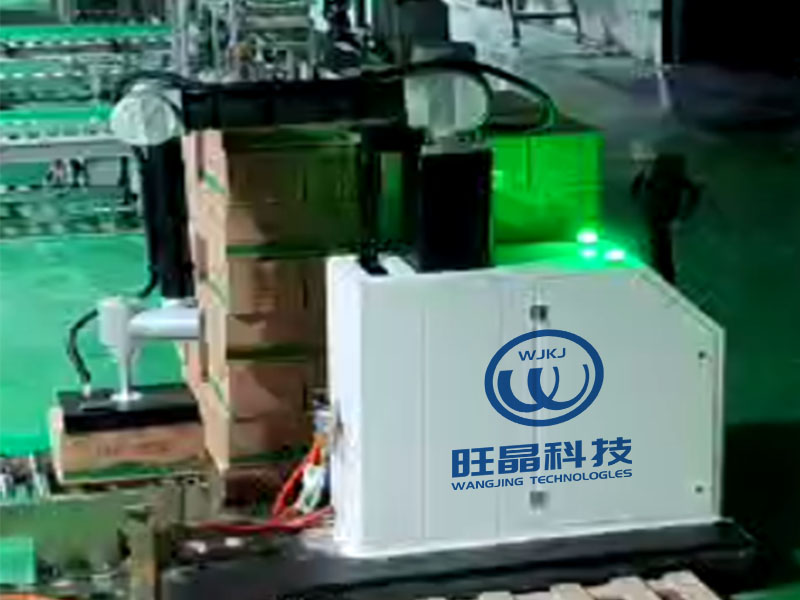

Advantages and Disadvantages of China's Artificial Intelligence Industrial Palletizing Robot

With the development trend of scientific and technological artificial intelligence, in industry, cooperative palletizing robots will undertake more and more tasks in industrial production, leading to industrial robots competing for jobs with people. At this stage, industrial palletizing robots and people have their own advantages. The palletizing robot is warmly welcomed by companies and enterprises for its advantages of reducing cost, strict management, high production efficiency, and high security. However, there are also some shortcomings and deficiencies on the premise, such as maintainability, lack of imagination, stability of safe operation, diversity of layout, etc.

Market outlook 2022-09-21

Therefore, we believe that it is self-evident that palletizing robots can reduce human costs and enh

Stacking robot can reduce labor cost and enhance enterprise competitiveness. Due to the high demand and dependence on labor in manufacturing, the labor cost in manufacturing is relatively high. Public data shows that the human cost of most manufacturing enterprises accounts for about 38% of the enterprise income, so how to reduce the human cost and improve the competitiveness of enterprises is very important for many manufacturing enterprises!

Market outlook 2022-09-22

We are now studying the problems faced by palletizing robots

Stacking robot is a kind of industrial robot, which is widely used at present. With the decline of labor rate and the rise of labor cost, palletizing robots are used more and more. Stackers and porters are manufactured in manufacturing enterprises to replace manual post packaging operations.

Market outlook 2022-09-28