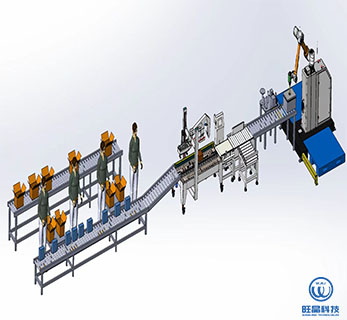

Equipment characteristics of palletizing robot production line

It is applicable to the palletizing robot production line, chemical plants, pharmaceutical industry, grain crops, fertilizer, food, decorative building materials, beverages, metallurgical industry, refractory insulation materials and other fields, and can be used for fully automatic packaging and palletizing of bags, whole boxes, barrels, cans, and boards. The palletizing robot production line is one of the indispensable packaging equipment in today's production line. Its basic function is to stack products and package and transport them normally.

Equipment characteristics of palletizing robot production line:

1. Compact structure and few parts. Therefore, the equipment failure rate of spare parts is low, the maintenance and repair are simple, and the spare parts that need to be stored are few

2. The total floor area is small. It is conducive to the layout of production line equipment in the customer's industrial workshop, and can free up a relatively large total warehouse area. The palletizing robot can be set in a narrow indoor space for carrying.

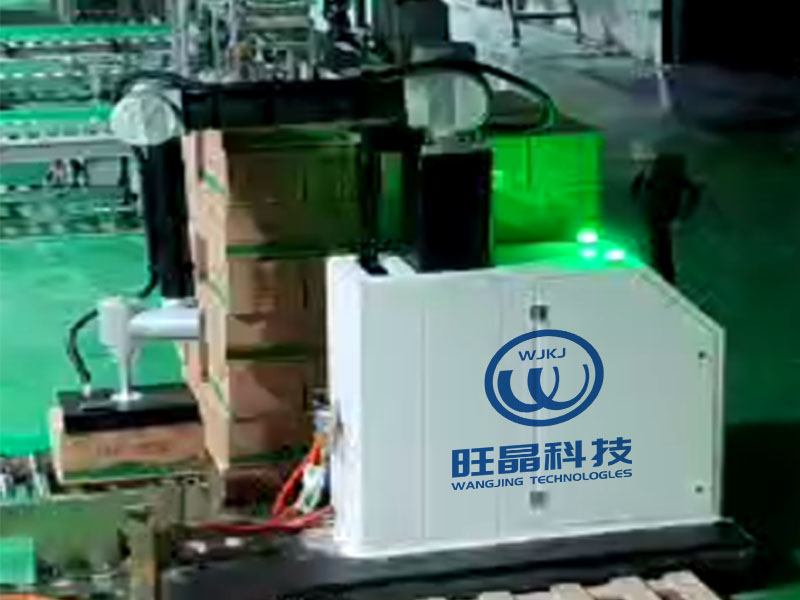

3. Strong scope of application. When the size, volume, appearance and pallet size of the customer's product change, just make a slight change on the touch screen, which will not affect the customer's normal production. But the replacement of mechanical stacker is very troublesome, even in the world.

4. Low energy consumption. The output power of the mechanical stacker is about 26KW, and the output power of the stacking robot is about 5KW. It can reduce the use cost of customers.

5. The weight operation can be completed on the control box screen, which is very convenient to use.

6. Just locate the starting point or landing point accurately, and the instructions are easy to understand.