Main application industries of cooperative stacker

In recent years, with the rapid development of food, beverage and health care industries, the intensity of manual stacking is high, and the rate of staff turnover is high, which has seriously affected the production management of food, medicine and other industries. With the development of science and technology, the emergence of automatic palletizing machine saves the time of product palletizing and helps enterprises to complete the transportation task better. Now let's take a look at the main application fields of automatic stacker

Market outlook 2022-09-29

The equipment manufacturing enterprises in the countries and regions along the "the Belt and Ro

The robotic production line for packing and palletizing helps manufacturing enterprises reduce staff and increase efficiency. In the production of many products, it is often necessary to count and package the products. If the traditional form of manpower is not only inconvenient, but also inefficient, high labor efficiency, it is not suitable for large-scale production.

Market outlook 2022-10-27

At present, robots have been successfully applied in many industries, including the working efficien

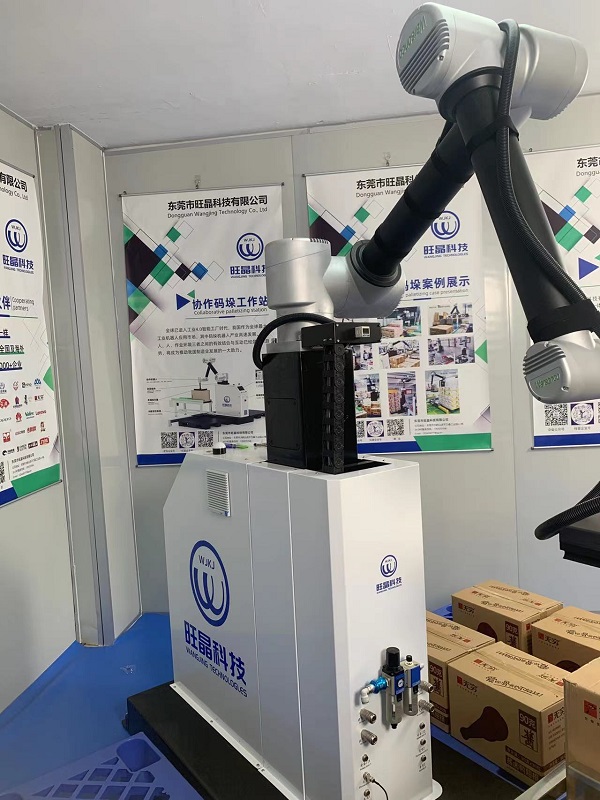

The definition of collaboration is more widely used in industrial scenarios. The cooperative mobile palletizing robot has replaced and improved the existing industrial robots, and has become the leading technology genre in the robot field with its higher safety factor, reliability and human coordination ability.

Market outlook 2022-11-01

Through robot palletizing, workers can achieve accurate control of robot palletizer gripper

The gripper of cooperative palletizing robot, also known as end effector, clamp and mechanical gripper, is an important part of the palletizing robot. The design of robot intelligent gripper generally uses image system to identify the size of the workpiece, and servo motor to adjust the spacing of the clamping plates.

Market outlook 2022-10-11

What is the basis for the normal and stable operation of our automatic stacker

Collaborative mobile has fully played the role of many industries to improve the whole process. Packaging robots are generally used for light practical operations to put objects or services into small boxes or pallets. The software of the cooperative stacking robot system has a compact and streamlined design, which can provide the stacking of small precision and speed boxes, water bottles, packaging bags, trays and cartons from medium to large payloads to super heavy payloads.

Market outlook 2022-10-27

What should we pay attention to when small and medium-sized enterprises choose cooperative robots?

Collaborative robots are used in the process of sorting out enterprise related emergencies, and can complete collaborative work that can only be completed by multiple people at a faster speed. This kind of robot is suitable for enterprises with gradual development of industrialization and scale, and can solve many difficult and complex problems. So what should enterprises pay attention to in the early stage of selecting cooperative robots?

Market outlook 2022-09-22

In this case, we can solve this problem by using the full automatic stacker.

Now, more and more enterprises use automatic stackers. It is worth noting that there are many skills to understand and master in the process of using automatic stackers.

Market outlook 2022-09-23

As the most advanced full-automatic palletizer in the world, Huawei is a good helper for enterprise

Many people have only a general understanding of stackers. They believe that the stacker is a simple mechanical equipment used for handling and stacking goods. In fact, the stacker is not just a simple mechanical equipment. Many production workshops have palletizing robots to load, unload and stack goods. The use of palletizing robots is several times more efficient than traditional labor, but it can also reduce the human cost of enterprises.

Market outlook 2022-09-28