The equipment manufacturing enterprises in the countries and regions along the "the Belt and Ro

The robotic production line for packing and palletizing helps manufacturing enterprises reduce staff and increase efficiency. In the production of many products, it is often necessary to count and package the products. If the traditional form of manpower is not only inconvenient, but also inefficient, high labor efficiency, it is not suitable for large-scale production.

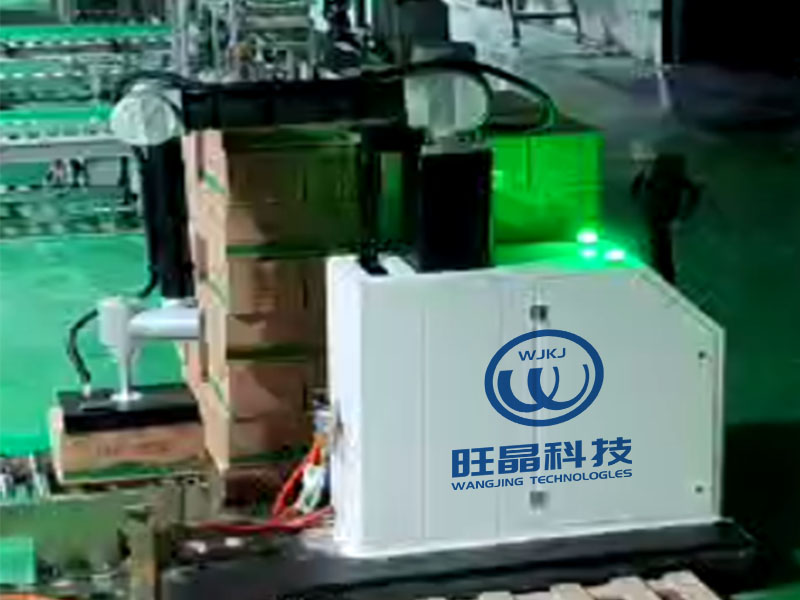

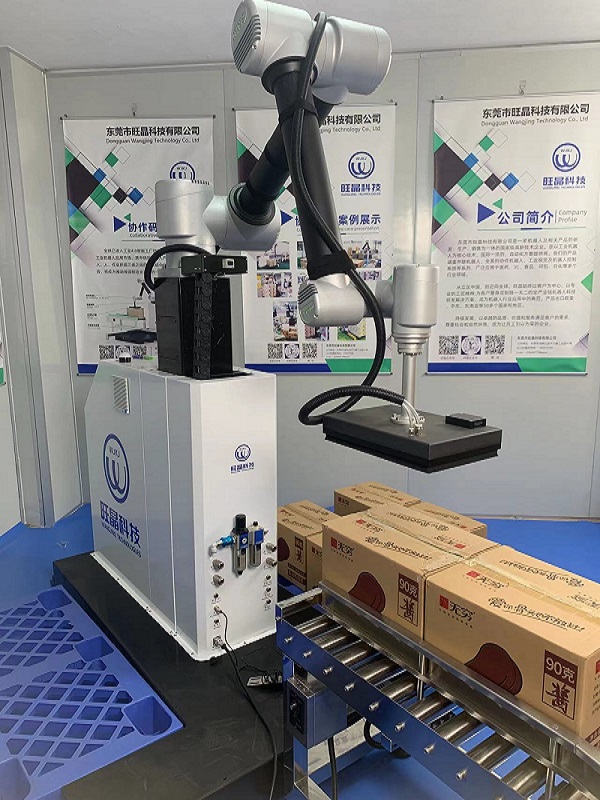

The robotic production line for packing and palletizing only needs one automatic machine to handle the packaging and packaging difficulties of most bottled products, which brings great convenience to manufacturers. The glass bottle packaging and stacking robot production line is generally composed of: packing case feeding conveyor belt, bottle product feeding conveyor belt, automatic packing point for bottle products, packing conveyor belt, packing case packaging equipment and packing case climbing and stacking machine. All production processes can be automated without manual participation.

Equipment installation, commissioning and supervision must be provided with relevant professional technicians. The whole process of machine operation can also be divided into two feeding belts, one is the feeding belt of the packing box, and the other is the feeding belt of bottled products. The two routes operate in the same way and converge at fully automated packaging points. When the product stays at the connection of the packing box, it is transported by the conveyor belt and placed in the packing box, then transferred to the mid-range full-automatic product placement baffle, and then transferred to the automatic packaging equipment. The automatic packaging device can open and close the packaging box, and then seal the outer packaging. The finished products are transported to the automatic stacker equipment, and the mechanical arm automatically crawls for stacking.

The boxing and palletizing robot production line is mainly used for bottled products, such as beverages and alcohol, and assists manufacturers in packaging and palletizing in the fully automatic packaging step. At the same time, the workflow can be improved or changed according to the product characteristics of different customer satisfaction and production capacity, such as labels, coding software, weighing, stretching and packaging film packaging stacked products.