Main application industries of cooperative stacker

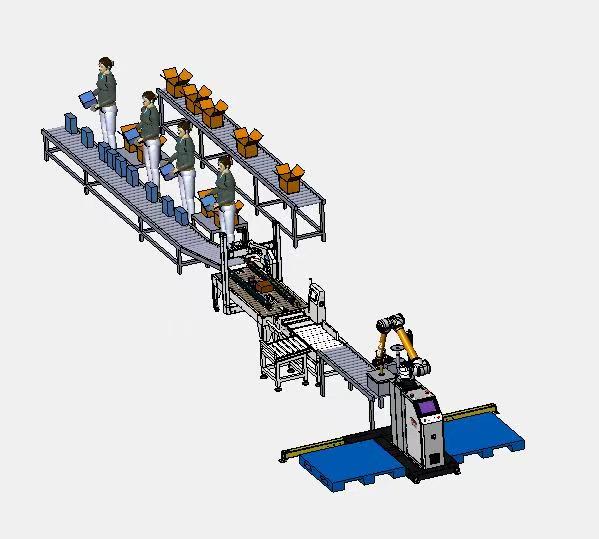

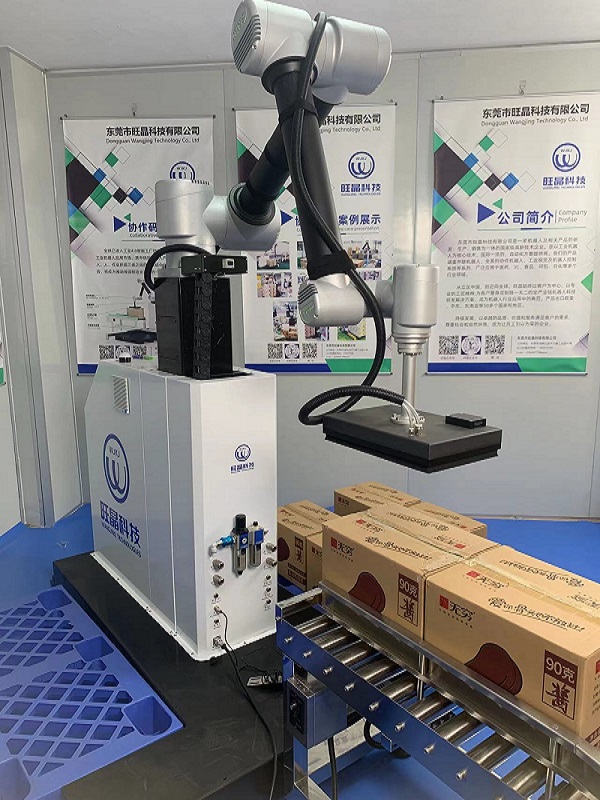

In recent years, with the rapid development of food, beverage and health care industries, the intensity of manual stacking is high, and the rate of staff turnover is high, which has seriously affected the production management of food, medicine and other industries. With the development of science and technology, the emergence of automatic palletizing machine saves the time of product palletizing and helps enterprises to complete the transportation task better. Now let's take a look at the main application fields of automatic stacker.

The automatic stacker is mainly used in chemical raw material plants, packaging plants and some large items. Some products harmful to human health, such as medicine, feed, fertilizer, microbial agents, etc. Automatic stacker has been widely used.

With the popularization of automatic stacking robot, it will be extended to more fields in the future, such as microbial agents, pharmaceutical and other industries. Stacking robot can replace human beings to complete high-risk and demanding tasks such as handling, loading and unloading, and help the industry develop more scientifically and stably.

The automatic stacker is mainly used in the following industries:

1. Automobile manufacturing industry

In China, 50% of industrial robots are used in automobile manufacturing, of which more than 50% are welding robots; In developed countries, robots in the automobile industry account for more than 53% of the total number of robots. According to statistics, there are more than 10 robots in every 10000 cars of the world's major automobile manufacturers. With the continuous development and improvement of robot technology, industrial robots will certainly play a huge role in promoting the development of automobile manufacturing. While China is moving from a manufacturing power to a manufacturing power, it needs to upgrade processing means, improve product quality, and increase the competitiveness of enterprises, which shows that robots have a huge development prospect.

2. Rubber and plastics industry

The cooperation in the plastic industry is close and highly specialized: the production, processing and machinery manufacturing of plastics are closely linked. Even in the future, this industry will also be an important economic sector. Because plastic is almost everywhere: from the automotive and electronics industries to consumer goods and food industries. As a technology connecting production and processing, manufacturing plays a vital role here. Raw materials are processed into innovative, fine and durable finished or semi-finished products through injection molding machines and tools for finishing - the production process is more efficient, economical and reliable through the use of automated solutions.

3. Food industry

Robots are used more and more widely. Even in many traditional industries, people are trying to let robots work instead of humans, and so is the food industry. At present, people have developed robots for the food industry, such as packaging and canning robots, automatic lunch robots and beef cutting robots.