With the continuous development of artificial intelligence technology, enterprises will benefit more

The use of automated production lines for mass production in enterprises can improve labor productivity, stabilize and improve product quality, improve working conditions, reduce production floor space, reduce production costs, shorten production cycle, and ensure production balance, which has significant economic benefits.

Market outlook 2022-10-11

With the rapid development of intelligent manufacturing, palletizing robot has become the mainstream

With the increasing popularity of automatic robot production, the cost of robots is also decreasing. In the past 30 years, the average price of robots has actually dropped by half, even exceeding the labor cost.

Market outlook 2022-10-06

How to maintain the case opener in winter?

Winter is coming. With the sharp drop of temperature, most objects become particularly sensitive in the cold weather in winter. In particular, the daily maintenance of various machines and equipment on the packaging production line in winter is crucial. As far as the unpacking machine equipment is concerned, once the temperature and other factors are abnormal, it will not only delay the reduction of enterprise productivity, but also bring many hazards to the enterprise. Today we will talk about how to maintain the unpacking machine in winter.

Market outlook 2022-09-18

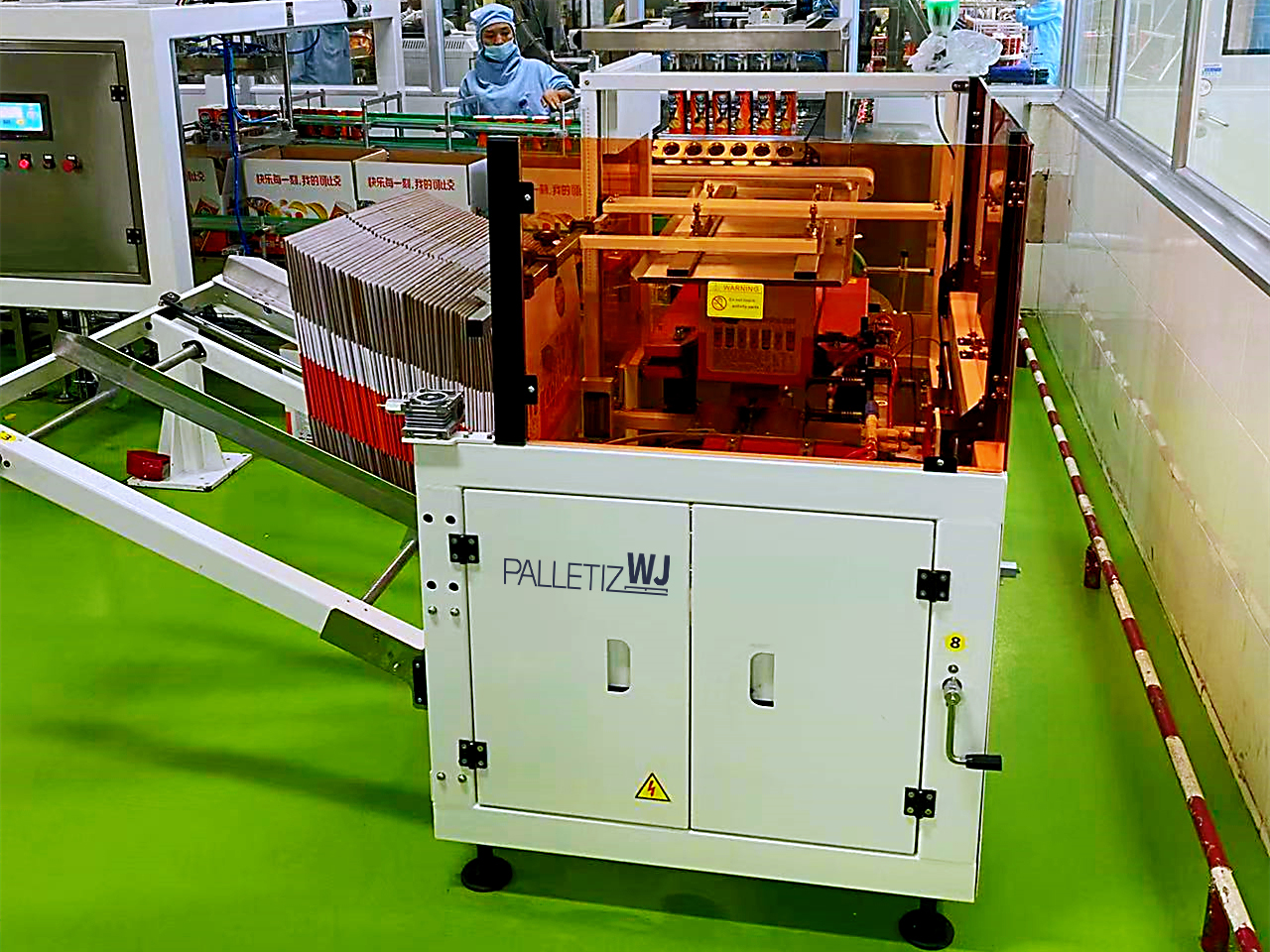

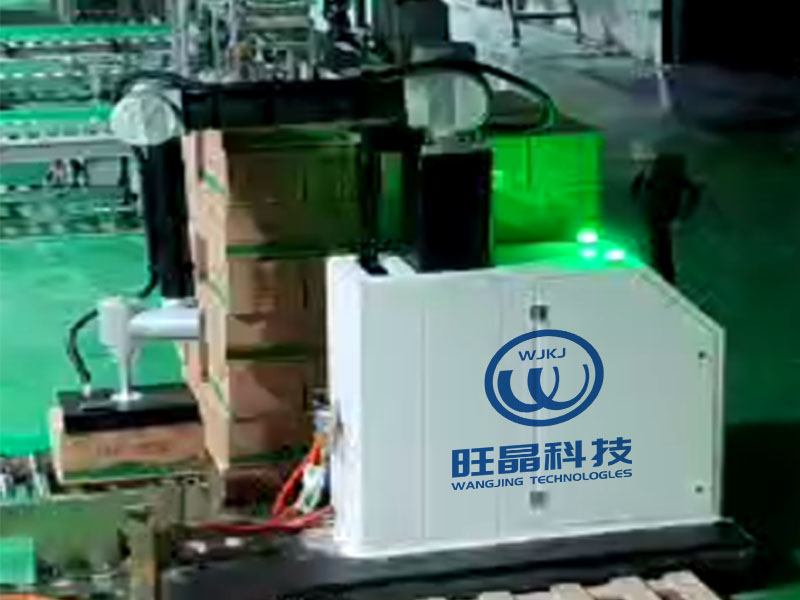

Stacker realizes unmanned factory landing in food industry

Industrial robots are the main force for "unmanned factory" to achieve production development, and also the key point for intelligent upgrading of manufacturing enterprises.

Market outlook 2022-09-15

The market scale of industrial robots in China has reached 17.3 trillion yuan, and stacking robots h

The disadvantages of manual palletizing of cooperative palletizing robot are pointed out: the palletizing form is irregular, the palletizing is often reversed, and there are potential safety hazards. In the loading process, due to the irregular stacking form, the loading capacity is low and the transportation cost is high. Low stacking efficiency and high labor cost.

Market outlook 2022-09-21

Stacking robot slowly replaces manpower

The palletizing robot presents a diversified development trend. It can replace the staff working in dangerous, continuous high temperature, toxic and harmful substances and other harsh environments, while ensuring product quality and improving work efficiency

Market outlook 2022-09-18

This is the important significance of our country to the automatic stacker

Automatic stacker is an industrial machine which has been widely used in recent years. It consists of three parts: chassis, stacker main body and conveyor. The position of the equipment can be adjusted freely according to the user's site conditions, from the initial step of the product to the offline. The appearance of automatic stacker represents a great progress in industrial automation, and also provides a great opportunity for social development and labor liberation. As an important auxiliary equipment for industrial assembly line production, its existence can reduce the total number of workers needed on the assembly line and improve industrial efficiency.

Market outlook 2022-09-28

Work flow of automatic palletizer production line

The fully automatic cooperative stacker is mainly composed of leveling belt conveyor, slow stop belt conveyor, transfer belt conveyor, tray bin, tray belt conveyor, arranging machine, bag pushing machine, stacker machine and stacker belt conveyor. Its automatic design ensures stable, safe and reliable posture. The working process of the stacker is fully automatic, and there is no need for manual control during normal operation, so it has a universal application field.

Market outlook 2022-09-20