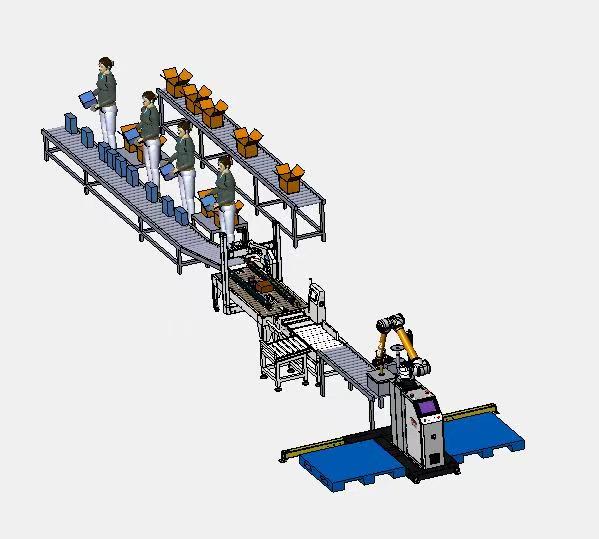

What we need to know is that this is the principle of a cooperative palletizing robot

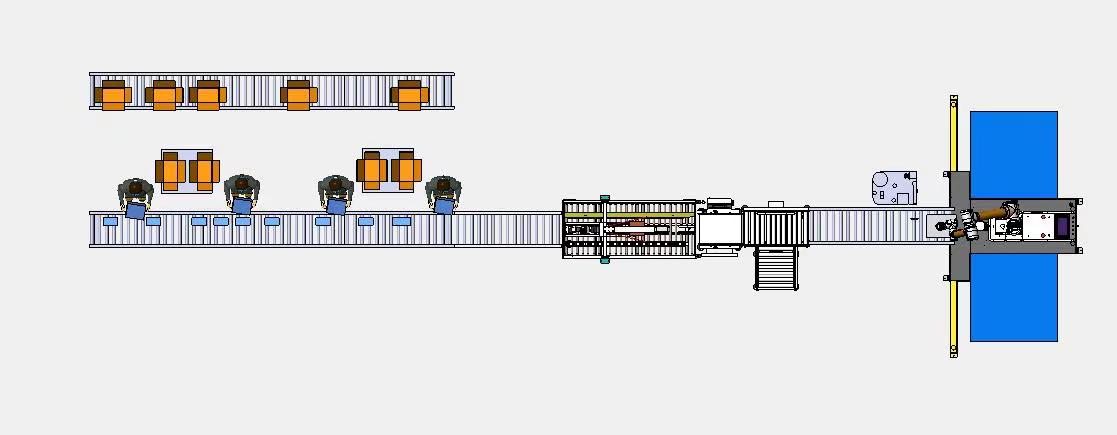

Most of the operations performed by the cooperative palletizing robot are grasping and placing operations, that is, the robot grabs materials from the conveyor belt and places them on the designated position on the pallet along the motion path. Therefore, according to the position relationship between the robot and the conveyor belt and tray when it completes stacking, and considering the obstacles in the movement process, the "door" shaped movement track is selected. It should be noted that when the robot end effector completes the stacking of cartons at different positions on the pallet, the trajectory is in the shape of a "door", and the coordinates of the trajectory end point are different only because the positions of cartons on the pallet are different.

The so-called stacking is to stack materials in a certain way according to the idea of integrated unit, so that the unit stacking can realize logistics activities such as storage, handling, loading and unloading, transportation, etc. Compared with traditional manual palletizing and gantry palletizing machines, collaborative palletizing robots have been gradually applied in various fields due to their high production efficiency, small space occupation, large flexibility and low labor intensity.

Commonly used palletizing robot grab

Claw type mechanical gripper: mainly used for high-speed bag stacking;

Clamping type mechanical gripper: mainly used for case stacking;

Vacuum suction mechanical gripper: mainly applicable to absorbable stacked objects;

Grasping mechanical gripper: mainly applicable to absorbable stacked objects;

Mixed mechanical gripper: suitable for collaborative grasping and placement of multiple stations.

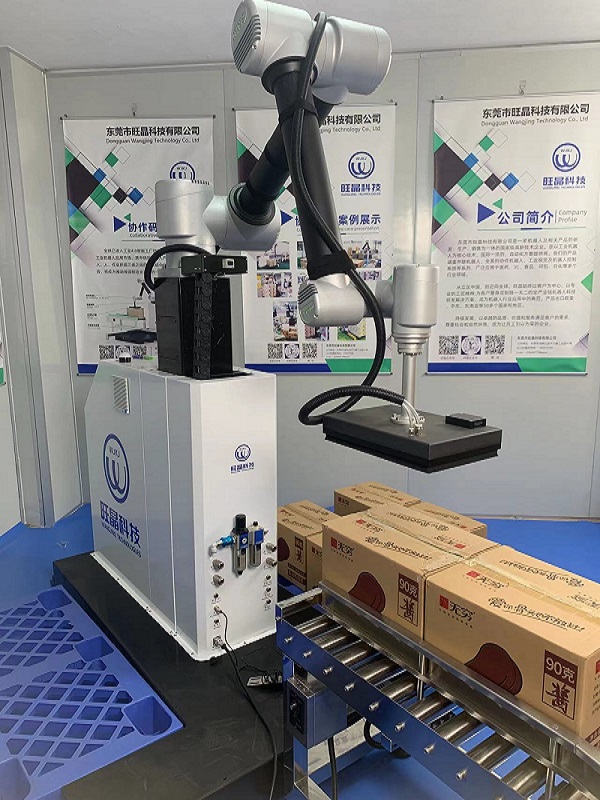

When using the stacking robot, it is important to consider how the robot grasps the product. The vacuum gripper is the most common end of arm tool (EOAT). Relatively speaking, they are cheap, easy to operate, and can effectively load most loads. However, in some specific applications, the vacuum gripper will also encounter some problems, such as porous substrate surface, flexible packaging liquid content, or uneven packaging surface.

Classification of palletizing robots

According to the different mechanical structures, the palletizing robot includes the following three types: double ear type, rotary joint type and gantry crane type.

Tical palletizing robot: It is mainly composed of four parts: column, X arm, Y arm and claw, and can realize material palletizing with four degrees of freedom (including three moving joints and one rotating joint). The stacker has simple structure, strong rigidity and large carrying weight, and is suitable for stacking heavier materials.

Rotary joint robot: the stacker rotates around the body, including four rotary joints: waist joint, shoulder joint, elbow joint and wrist joint. This kind of stacker is programmed through teaching, that is, the operator holds the teaching box and controls the robot to move according to the specified action. Therefore, the moving process is stored in the memory and can be reproduced in the future automatic operation. This kind of robot has small volume and large range of motion, can stack one or several pallets at the same time, and can work flexibly on various product production lines.

Gantry crane: the mechanical arm is installed on the gantry crane and is called gantry stacking robot. The palletizing robot has a wide working range and can grasp heavier materials.

Cooperative palletizing robots are widely used to stack and unload various packaging products, such as nylon bags, paper bags, plastic bags, cartons, plastic containers, glass bottles and PET bottles.