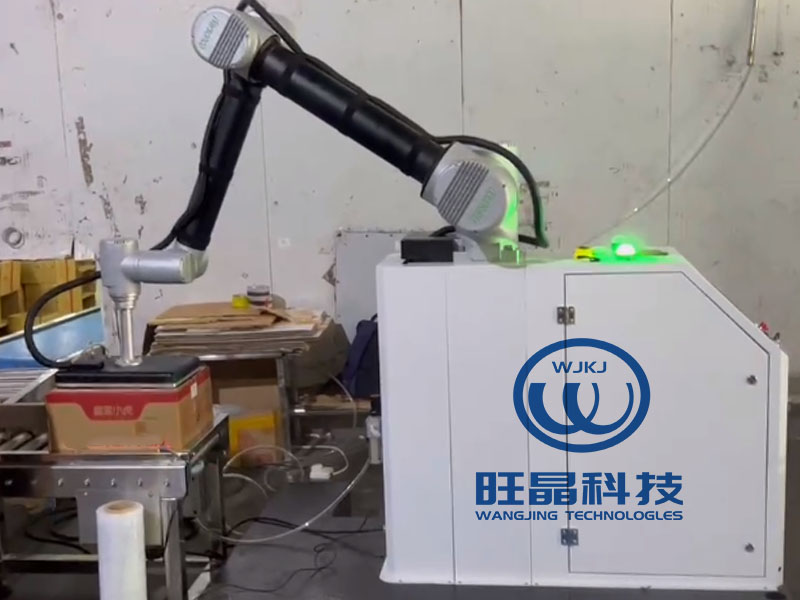

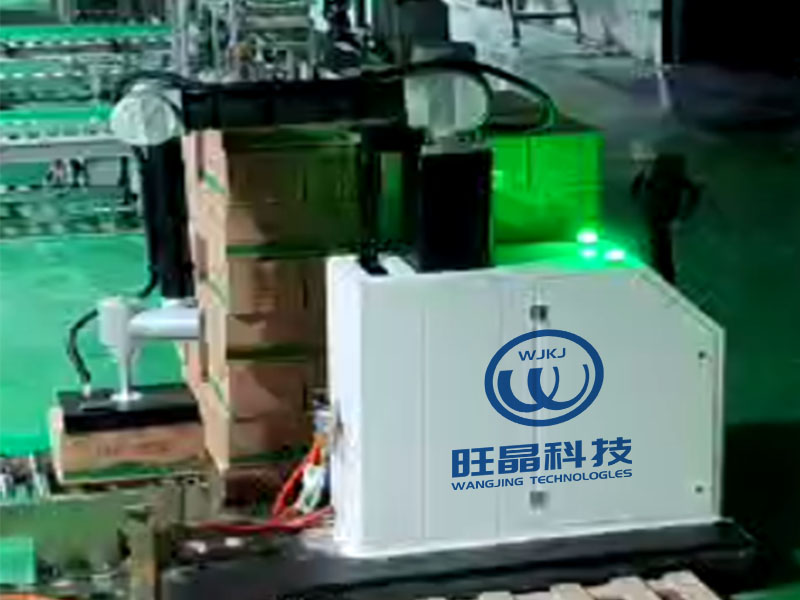

The company's main business is the R&D, production and sales of palletizing robots, and the R&am

Data shows that the stacker production line is widely used in the world, with food enterprises accounting for a very high proportion, followed by medicine, chemicals, beverages, dairy products, agriculture and animal husbandry. With the rapid development of the logistics industry, the application of the upper layer palletizing machine palletizing production line in the refrigerated storage logistics center is more and more.

Which process will use high-low stacker/stacker line?

At the factory level, raw materials are unpacked, processed and bagged after warehousing. Then, the belt conveyor palletizes the process flow area of the palletizing robot for warehousing of finished products. Logistics, warehousing logistics and other logistics distribution centers are similar. The products are warehoused, moved into the automated warehouse, unpacked, stored by category, and finally sorted by the stacker through express delivery, and then mixed in and out by the electric forklift.

In 2017, the total number of applications from SMEs has significantly exceeded that of large enterprises. So, what are the characteristics of such a stacker/stacker production line for large enterprises and small and medium-sized enterprises?

Small and medium-sized enterprises will give full consideration to the application of stackers when building industrial plants to replace manpower. In the dimension field, small and medium-sized enterprises generally like this kind of low specification intelligent robot with very low price, very low capacity and small capital investment in the middle and late stages. The key function is to save my studio space.

There are some differences between large enterprises, whose key purpose is to improve productivity by making production lines reasonable. Not only will robots be fully considered when building new industrial plants, but also robots will be upgraded and hospital bed stackers will be purchased. At the model level, large enterprises generally choose intelligent robots with high capabilities and functions to integrate their entire conveyors.

First, the food, freight logistics and medical industries are in great demand.

Second, the application of electric forklift around warehousing operations is generally accompanied by the application of stackers.

Third, at the level of regional SMEs, no one can ignore it. Due to the difficulty in recruitment and rising labor costs, we also attach great importance to mechanical automation and automation technology.

Fourth, matching window problem, freight logistics processing and manufacturing industry, corresponding customers, logistics departments, etc.

Fifth, in each factory, palletizing and unstacking are the most critical automated process flow in the process of developing automation technology.