How about the stacking efficiency of the stacking robot?

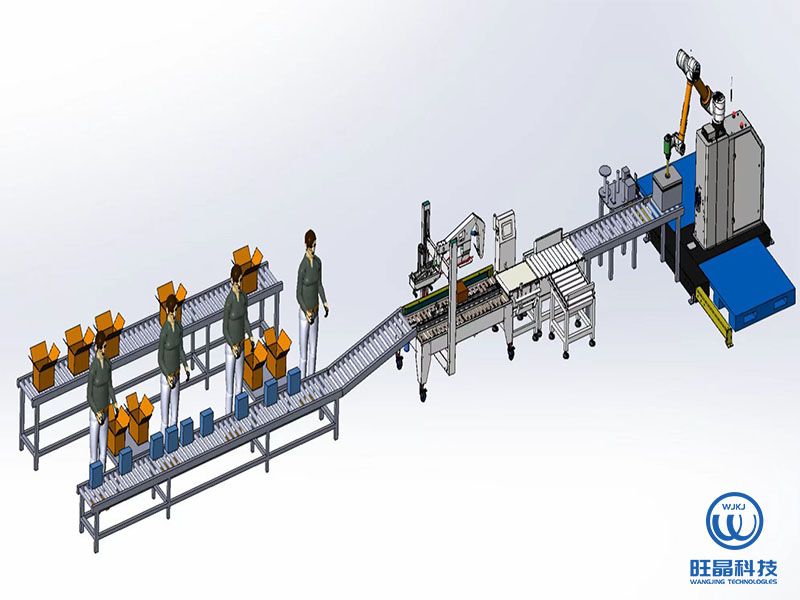

With the rapid development and optimization of automatic machines, palletizing robots are gradually applied.

It is applicable to all kinds of industries, and it can be used as a small and medium-sized stacking machine to replace manual stacking. The cooperative palletizing robot is widely used in the automatic palletizing of powdery and granular raw materials and standard articles of a certain volume in the petrochemical, food, pharmaceutical, concentrated feed, nonferrous plate ore, decorative materials industry, and the automatic and fast palletizing of all kinds of cartons. What advantages does palletizing robot have in grain, oil and food packaging?

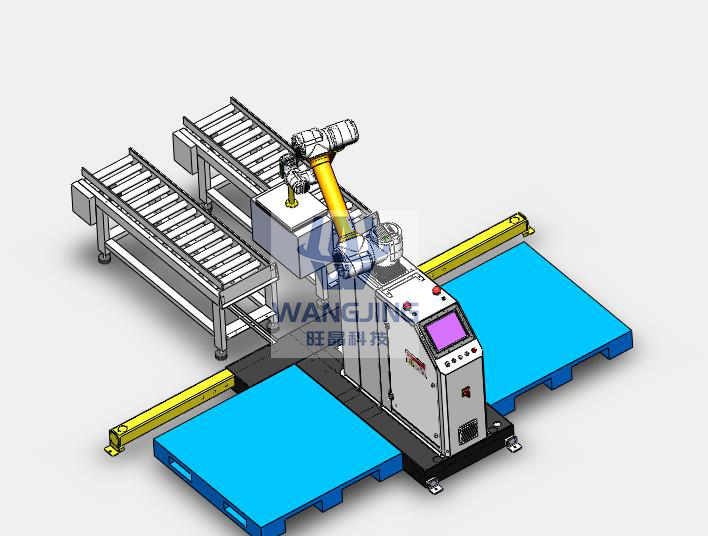

1. The cooperative palletizing robot covers a small area, which saves indoor space for the grain and oil factory and can also be used to store other items.

2. The cooperative stacking robot can also stack at the same time with high efficiency and is not easy to collapse.

3. The cooperative stacking robot replaces manual operation, reducing the long working time of workers under soot conditions. The palletizing robot can also transport and stack with high toughness in various harsh environments.

4. It can improve efficiency and meet the production requirements of most small and medium-sized enterprises.

5. Simple structure, low cost, durable and maintenance free.

6. The mode can be set according to the natural environment requirements of on-site work, and irregular shaped finished products can be loaded and stacked.

The application of collaboration equipment in the stacker has affected the traditional manual production process, improved the automation level of the factory production line, and promoted the development of the times. Stacking robots are also suitable for automatic packaging in many industries, such as food, health drinks, daily chemicals, electronic devices, communications, pharmaceuticals, lighting, auto parts, etc.