So, what is the significance of this technology's automatic palletizer?

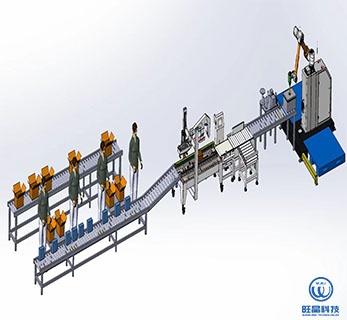

Automatic stacker is an industrial machine which has been widely used in recent years. It consists of three parts: chassis, stacker main body and conveyor. The position of the equipment can be adjusted freely according to the user's site conditions, from the initial step of the product to the offline. The appearance of automatic stacker represents a great progress in industrial automation, and also provides a great opportunity for social development and labor liberation. As an important auxiliary equipment for industrial assembly line production, its existence can reduce the total number of workers needed on the assembly line and improve industrial efficiency.

In the era of mechanized production, from ancient times to the present, we can find that through our continuous use of system automation machinery, we can maximize the use of labor and production management efficiency of related products. Now the appearance of automatic stacker has also realized a great liberation of human resources in social life. In a factory, the production line of an enterprise needs many workers, and different jobs are divided into different groups. Now there is a code stack robot, which can save the manual use of a process, reduce the use cost of the factory, and speed up the production efficiency of products. This is a great progress for the whole world development history. This success has liberated a batch of labor force, and the production efficiency of products has been continuously improved, which is also a great benefit for manufacturers.

The automatic stacker can replace the manual work to sort, transport, stack, load and unload goods, and can work all day. It is generally used at the end of the production line to stack bags, boxes, barrels and other materials on the production line to the pallet according to the set rules, and then store them in the warehouse with a forklift. According to different product types and actual requirements, the automatic stacker is programmed to meet the stacking requirements of various products.

With the development of logistics and other industries, automatic stacker plays an increasingly important role. It can not only complete product stacking accurately and effectively, but also reduce labor intensity of workers and improve product quality.

With the progress of science and technology and the acceleration of the modernization process, people have higher requirements for loading and unloading speed. Stacking robots have begun to appear. The palletizing robot is an intelligent service robot that loads goods onto pallets. It is neat, clean and automatic. In practical application, its problems greatly improve productivity, reduce labor intensity of workers, and can give full play to its effective role.

In a word, the application of automatic stacker in various industries has played a great role in solving the employment problem of manufacturing enterprises and reducing labor costs. It is precisely because of the importance of automatic stackers in the manufacturing industry that China should constantly improve the development vitality and core competitiveness of the intelligent automation equipment industry to better serve domestic manufacturing enterprises.