What should be paid attention to when selecting the sealing machine?

With the continuous improvement of the degree of automation, more and more enterprises are gradually transforming and upgrading from the original manual to production automation. The introduction of automation equipment has improved the production capacity and personal image of the enterprise, thus improving the production efficiency of the enterprise.

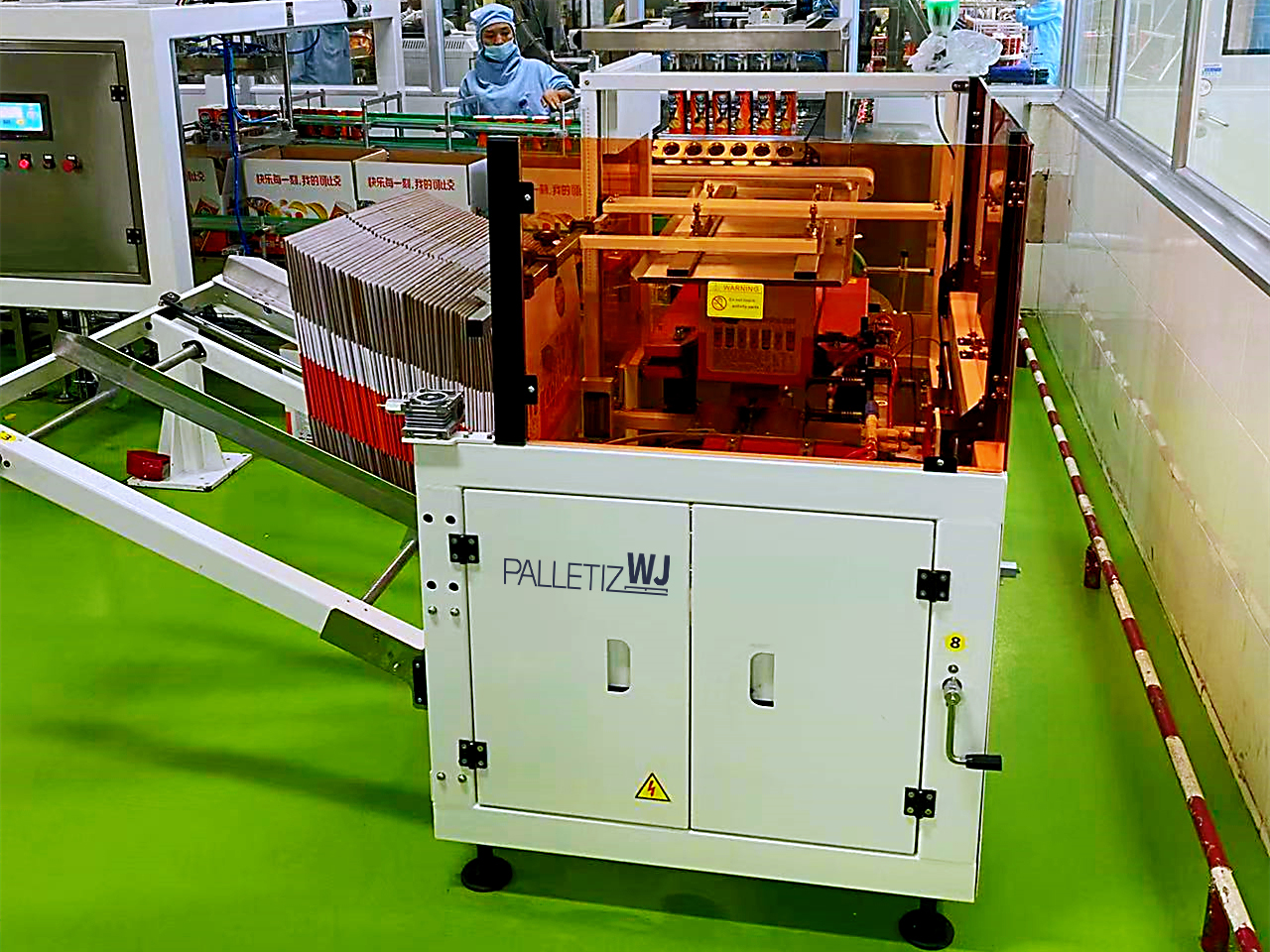

Take the entire outer packing box as an example. Traditionally, packaging is done by hand. However, after the advent of the case sealing machine, there was no need for manual work before. Some sealing work is automatically completed by machines and equipment. The sealing machine is unique, smooth and efficient. More and more enterprises will choose to use the sealing machine. What should we grasp when choosing the sealing machine? What should we pay special attention to when selecting the sealing machine?

1. You need to see if your business premises have interior space design. If there is no indoor space design, there is no way to place machinery and equipment.

2. You need to know the maximum and minimum models and specifications of your carton. Only in this way can you really master the use of standard equipment and whether it is non-standard equipment, so that you can better seal all your cartons. If you are not clear, you will be in a hurry if some paper boxes cannot be sealed when buying mechanical equipment.

3. The production capacity of your enterprise is to improve the efficiency of the case sealing machine. If the machine efficiency cannot reach the capacity of your enterprise, it is unnecessary, so you need to know the approximate capacity. Please help us choose the right device for you.

4. In addition, are there any special provisions for some spare parts when selecting the equipment of the case sealing machine, such as motors, PLC, cylinders, roller bearings, etc? You should tell it to everyone, so that everyone can help you make a suitable equipment for you, so that you can buy with confidence and use with warmth.