In the field of industrial robots, what are the application scenarios of intelligent manufacturing a

The important role of cooperative palletizing robot is to reduce the cost of manual logistics and facilitate the grabbing, handling and placing of goods.

People often find them in various express collection points, factories and other industrial scenes.

In recent years, with the cooperative mobile palletizing robot system becoming more efficient, fast and accurate software, cooperative mobile palletizing robot has been gradually applied in many companies.

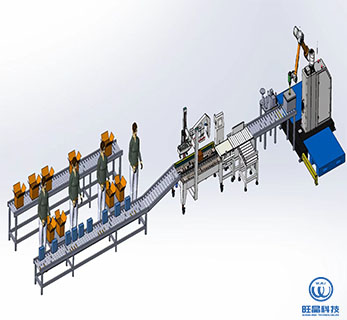

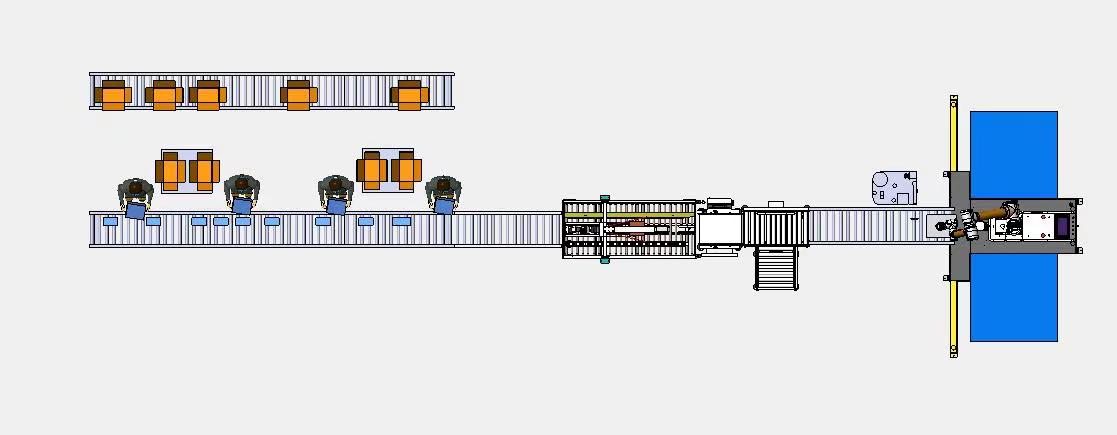

The cooperative mobile stacking robot needs to be equipped with a cooperative mobile stacking robot workstation, which is composed of a cooperative intelligent robot, a power box control board, a vertical rod adjusting shaft, a base+board precise positioning structure, an end effector and an operating system. We can operate the workstation, set up the stacking program flow, open the program and use the required factory's stacking collaborative intelligent robot.

After the workstation is installed, the cooperative mobile palletizing robot can also be applied to the following scenarios

Stacking is an indispensable process in transportation, which is suitable for ordering large quantities of goods in a certain way. Automated procedures make it easier to transport, unload and store items.

Compared with the traditional manual handling, the palletizing robot has the advantages of high efficiency, convenience and speed.

Therefore, the palletizing robot can be used in most operations that need to transport new products, whether in large and medium-sized factories or in daily needs.

As the processed products become more and more colorful, the transportation of some equipment must be more meticulous, with higher reliability requirements and higher labor costs. The appearance of cooperative mobile palletizing robot can just solve the most important handling and unloading functions in transportation.

At present, palletizing collaborative intelligent robots are widely used in catering, pharmaceutical, 3C, daily chemical, e-commerce and other industries.

According to secret recipe management and data visualization design, it can flexibly solve a variety of different packaging schemes, greatly reduce the time for changing production lines, and improve efficiency. The setting of palletizing robot workstation is the decisive factor for the smooth operation of the equipment.