What are the characteristics of this automatic production line operation mode

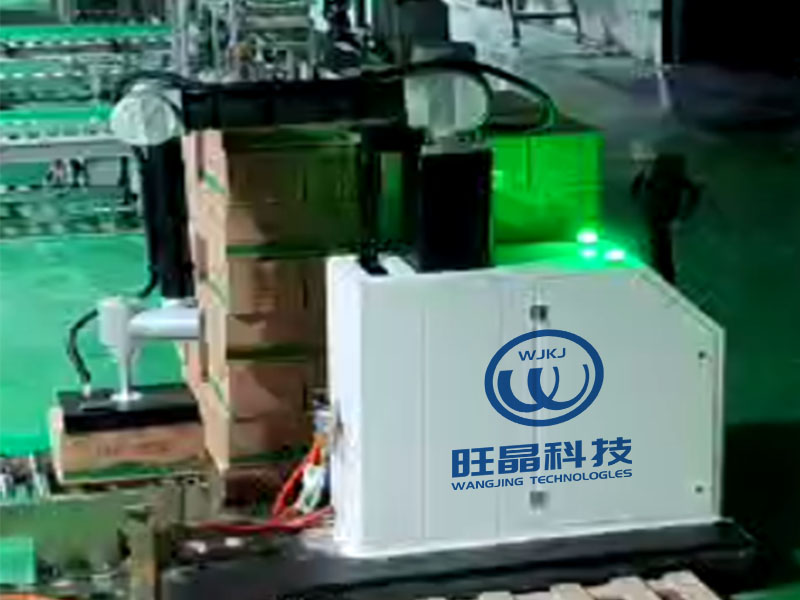

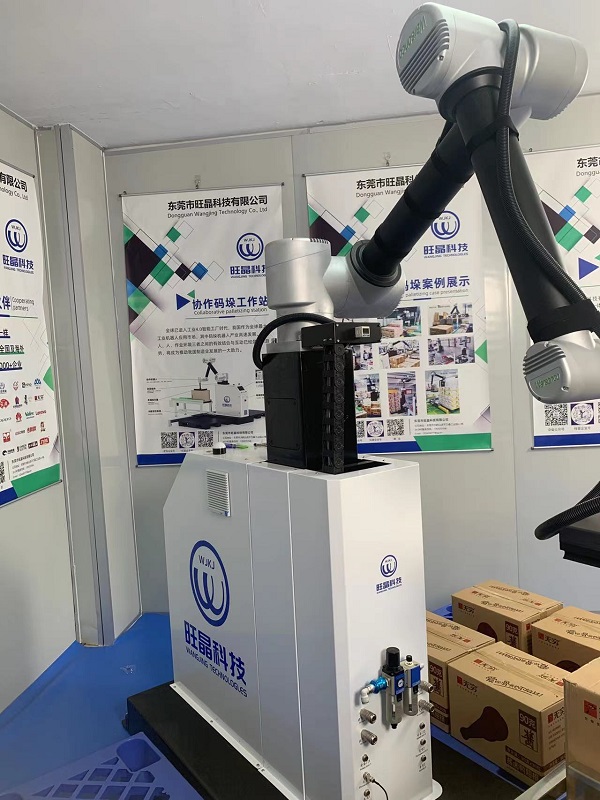

The automatic packing machine can automatically arrange the products according to the packaging requirements. It is an intelligent automatic packing machine. What are the characteristics of automatic production lines? The combination of four-bar linkage, motion, landing and electrical control realizes automatic coordination and action.

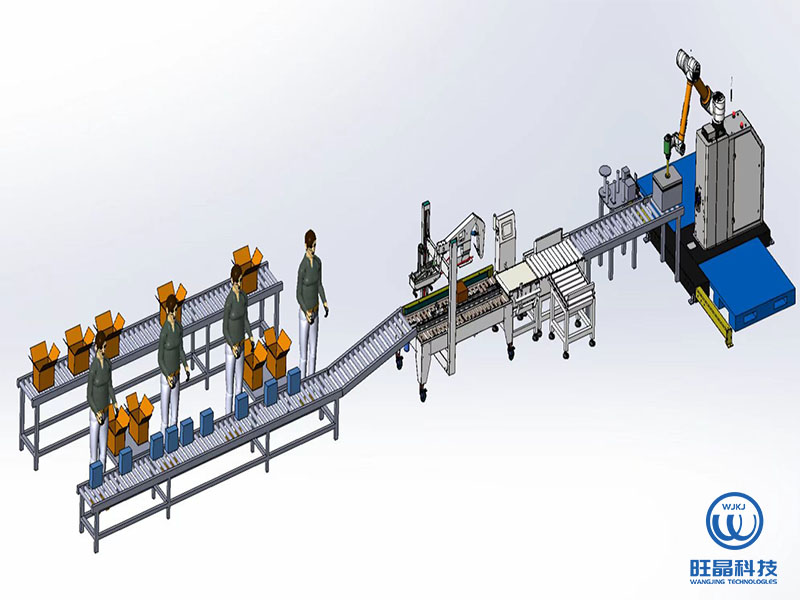

The automatic packing machine is composed of basic process equipment, various auxiliary equipment, control system and workpiece transmission system. According to the specific conditions of products or parts, process requirements, process requirements, productivity requirements and degree of automation, the structure and complexity of automatic lines often vary greatly. However, general automatic lines are composed of several basic parts. For specific automated production lines, their components are not identical. According to the structural characteristics, it can be divided into general equipment automatic line, special equipment automatic line, automatic line without storage device and automatic line with storage device.

Features of automatic production line:

1. The process operation and auxiliary work of products or parts at each station as well as the transportation between stations can be carried out automatically, with a high degree of automation.

2. The production rhythm is more strict, and the residence time of products or parts at each processing position is equal or multiple.

3. Product objects are usually fixed or vary in a small range, and a large amount of time is required for manual adjustment when varieties change.

4. The whole line has a unified control system, and electromechanical integration technology is widely used.

5. More initial investment in automated production lines.

Advantages of automated production line:

1. The use of automobile production lines to organize production is conducive to the application of advanced science and technology and modern enterprise management technology, can simplify the production layout, and reduce the workload of production workers.

2. The products produced by the automatic production line should have sufficient output. The product design and process shall be advanced, stable and reliable, and remain basically unchanged for a long time. The application of automatic line in batch production can improve labor productivity, stabilize and improve product quality, improve working conditions, reduce production area, reduce production cost, shorten production cycle, ensure production balance, and have significant economic benefits.

Automatic production line is a process of automatic operation or control according to specified procedures or instructions without any intervention. Its goal is "stable, accurate and fast". Automation technology is widely used in industry, agriculture, military, scientific research, transportation, commerce, medical treatment, service and family. The use of automatic production lines can not only liberate people from heavy physical labor, some mental labor and harsh and dangerous working environments, but also expand the functions of human organs, greatly improve labor productivity, and enhance human ability to understand and transform the world. The automatic production line can design different packaging specifications according to needs.