Development Trend of Stacking Robot

As an intelligent robot, palletizing robot is widely used in various manufacturing industries. The use of automatic palletizing robot equipment can greatly improve the efficiency, which is the most widely used in enterprise production, with the most obvious effect. It can not only realize accurate stacking operation, but also be very efficient.

At present, the production mode of enterprises is changing from traditional habits to modern automation habits. The rapid development, low error rate and rapid production of enterprises have become important indicators of enterprises, and also a breakthrough to reduce enterprise costs. As a fully automatic collaborative palletizing robot, it is widely used in all walks of life, and should not be underestimated. The low production efficiency of enterprises has increasingly become an obstacle to China's economic development, and the demand for efficient production is growing. Automatic palletizing robot is a good way to solve this problem.

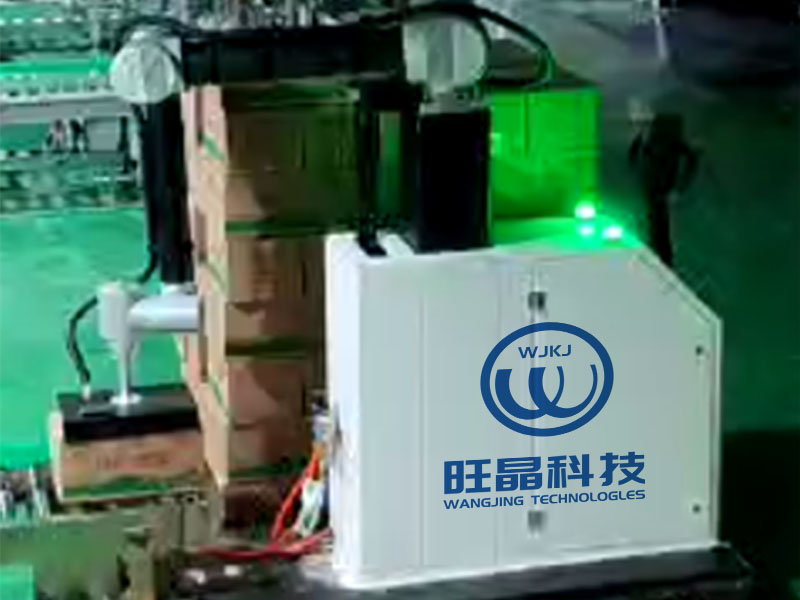

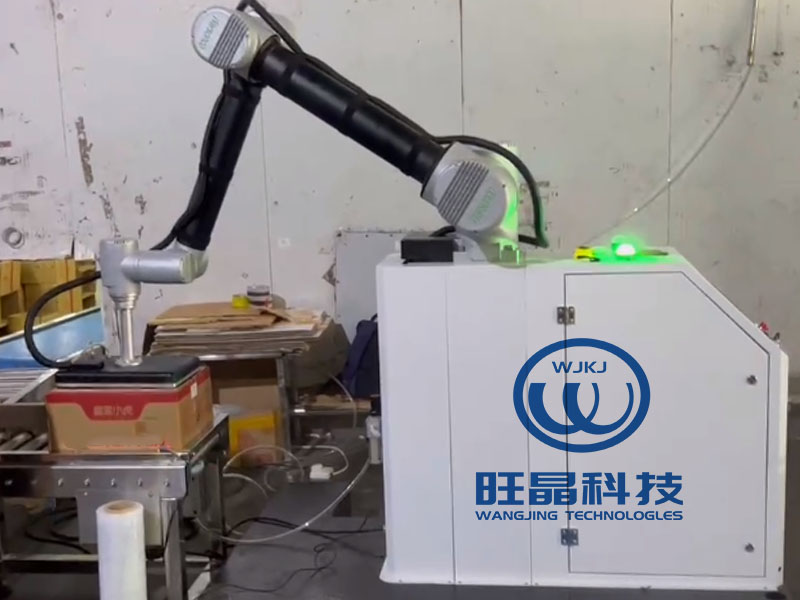

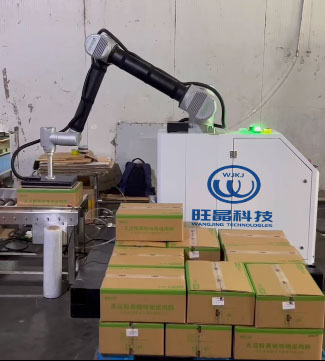

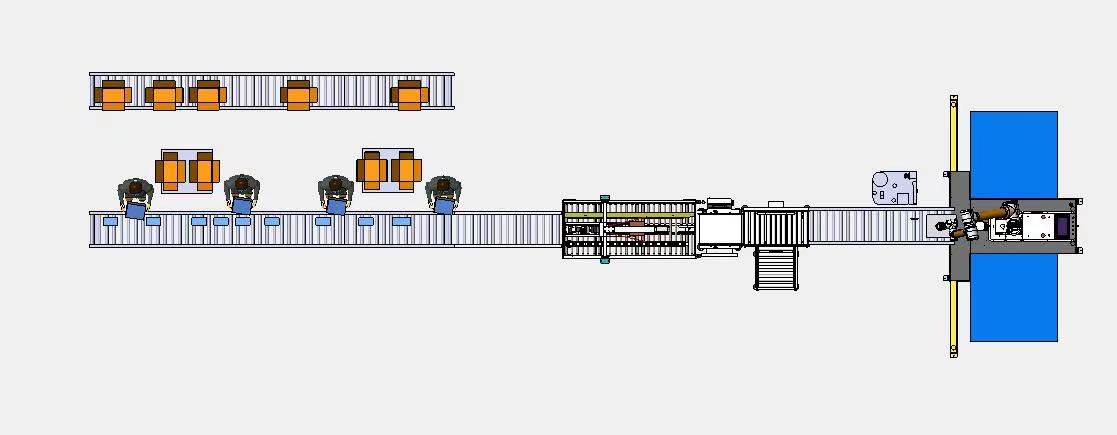

Scope of application Cooperative palletizing robot 3360 corrugated box, plastic box, barrel packaging, bag packaging. Equipment, carton input and sorting device, lifting and stacking device, pallet stacking and automatic feeding device, actual stacking and discharging device. The touch screen operation is adopted to realize man-machine dialogue, and the production speed, fault cause and location can be displayed, with a high degree of automation. An electric induction device is arranged on the safety door and the cover. When the cover door is opened, the machine stops working and can protect people. The stacking mode can be adjusted easily on the touch screen. Stacking is stable and efficient, which can greatly save manpower. The carton supply system is controlled by the brake motor to ensure that the carton is transported in the preset position. Multiple stacking modes can be achieved without replacing stacking parts.

The fully automatic cooperative palletizing robot has many excellent characteristics. It integrates handling and palletizing, and will certainly become the darling of the enterprise market. Palletizing is a relatively important part of an enterprise, which carries the quality of service and the palletizing function. As an important equipment, the palletizing robot will have a profound impact on the quality of service.