Characteristics of cooperative palletizing robot

Cooperative palletizing robot has brought fundamental changes to the future industrial production and factory manufacturing, and cooperative palletizing robot has decisive and important advantages

1. Lightweight: make the robot easier to control and improve safety.

2. Friendly: The surface and joints of the cooperative stacking robot are smooth and flat, without sharp corners or gaps that are easy to hurt the operator.

3. Perception: Perception of the surrounding environment, and change their actions and behaviors according to the changes of the environment.

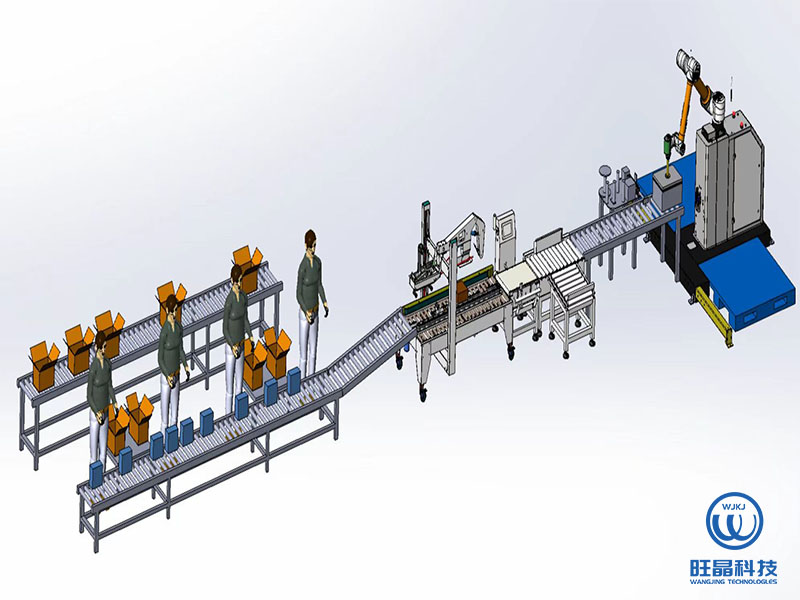

4. Man machine cooperation: it has a sensitive force feedback feature, and will stop immediately when the set force is reached. After risk assessment, it is unnecessary to install protective fence, and people and robots can work together.

5. Convenient programming: programming and debugging are very easy for some ordinary operators and people with non-technical backgrounds.

Advantages of cooperative robots

Cooperative palletizing robot has brought fundamental changes to future industrial production and factory manufacturing. Cooperative palletizing robot has decisive and important advantages:

1. Maximum flexibility in the production process.

2. Undertake manual processes that could not be automated before and did not conform to ergonomics, so as to reduce the burden on employees.

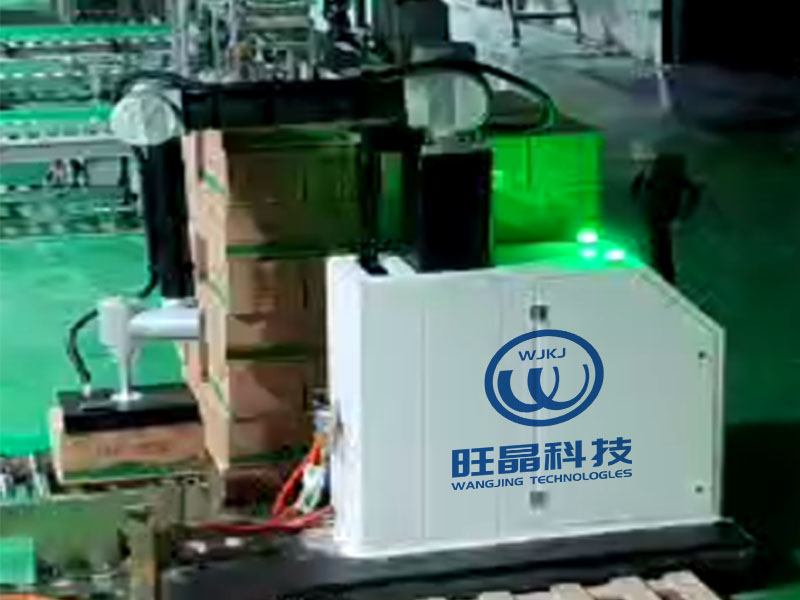

3. Reduce the risk of injury and infection, such as using dedicated human-computer cooperative grippers.

4. Complete the repeatable process with high quality, without investment according to type or workpiece.

5. Built in sensing system is adopted to improve productivity and equipment complexity.

Based on the advantages of human-computer cooperation, a more flexible cooperative robot becomes a feasible solution for assembly and extraction. It can give full play to the advantages of humans and robots, so that robots can better cooperate with workers and adapt to broader work challenges.