With the development of automatic stackers, automatic stackers are used more and more widely, and mo

The labor intensity of manual stacking is high, and the turnover rate of post labor is high, which has a serious impact on production management. With the development of science and technology, the appearance of automatic stacker saves time and energy for product stacking, and can better help enterprises to complete transportation tasks.

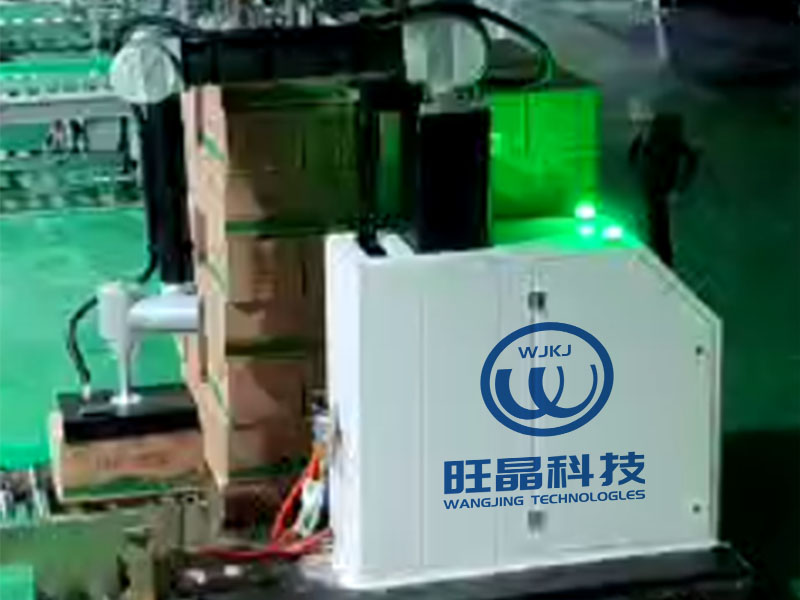

With the development of automation technology, the equipment of automatic stacker has also been improved and upgraded. Automatic stacker is a high-tech product of electromechanical integration. Medium low stacker can meet the needs of medium low production, while automatic stacker is more suitable for batch production. The automatic stacker can complete the stacking of various products according to the required grouping mode and layers. The design is optimized to make the stack compact and tidy. The automatic palletizing system can greatly reduce the number of workers and labor intensity. It is a high-tech product developed in modern industrial society, which is of great significance to improve productivity and reduce costs.

At present, the application of palletizing robot is more and more extensive. The palletizing robot not only has a single palletizing function, but also can be used as a loading and unloading robot. Stacking robots are mainly used in chemical raw material plants, packaging plants and some large objects. Some products are harmful to human health, such as medicine, feed, fertilizer, flour, cement, microbial agents, etc. These harmful product stacking robots are widely used. Industry insiders said that with the popularity of palletizing robots, it may expand to more fields in the future, such as microbial agents, pharmaceutical and other industries. Stacking robot can replace human beings to complete high-risk and demanding handling and loading tasks, and help the industry develop more scientifically and stably.

With the development of the times, the stacking process of products has changed from the original manual mode to mechanical automation and roboticization. The more and more advanced stacking methods show that China's machinery manufacturing industry is increasingly developed. Highly automated and intelligent mechanical equipment will help all industries in China to achieve more efficient, safer and more convenient production, management and operation, and help China's economy develop more stably.