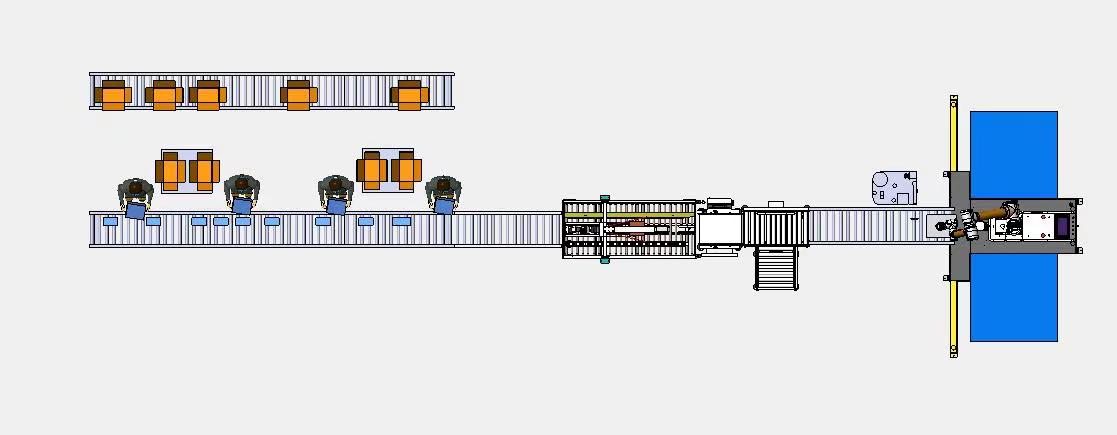

The biggest challenge we are facing now is what are the core technologies of cooperative robots? Wha

The key technologies of cooperation include robot vision, sensors and control systems. The difficulty lies in how to realize the cooperation between robots and how to deal with the behavior of robots in complex environments.

For your understanding, the following details are given:

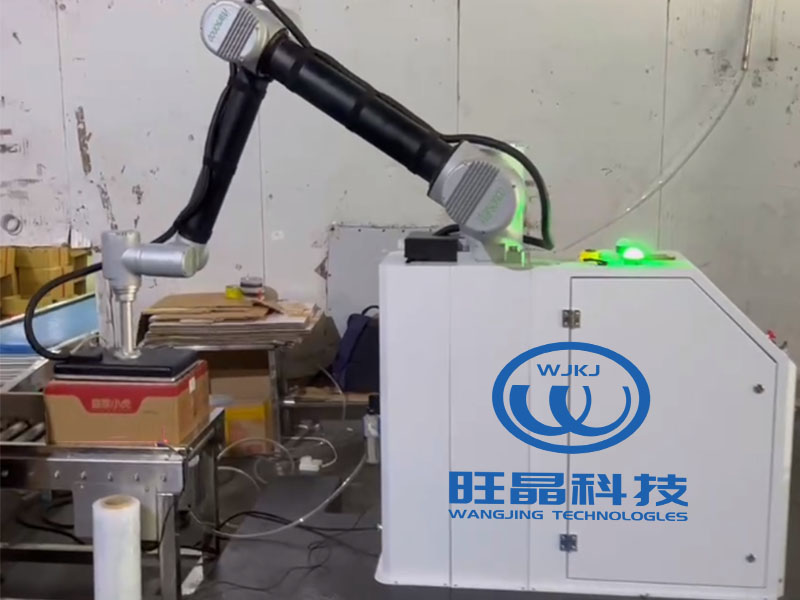

1、 The robot vision sensing technology enables the robot talents who can detect the surrounding environment to achieve cooperation. The difficulty is that the robot vision technology must be precise and accurate to correctly identify the surrounding objects and environment.

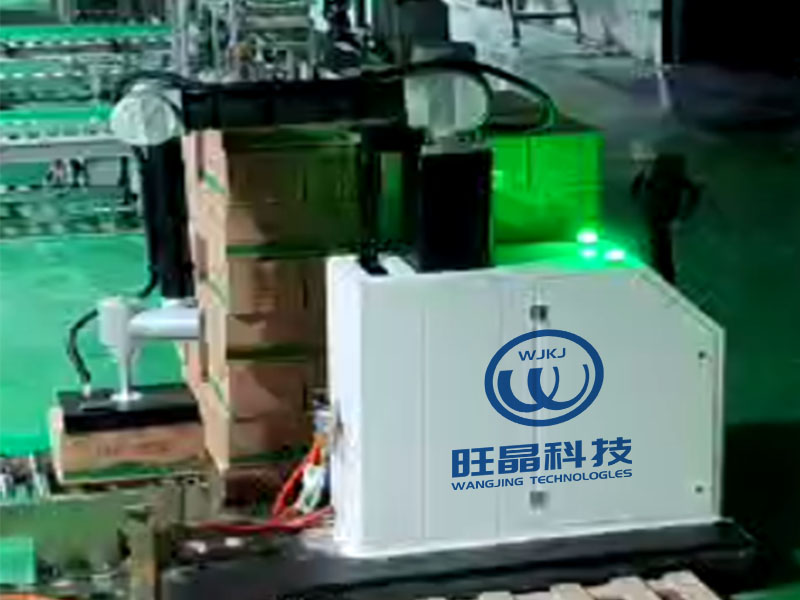

2、 It is the robot operation technology, including the ability of program development, algorithm design and optimization.

3、 Robotic information processing technology includes computer network technology, database technology, intelligent computing and data mining technology.

4、 Robot safety control and detection technology, including the stability, reliability, disaster relief and other capabilities of intelligent robots in various extreme environments.

5、 Robot system integration and services, including R&D capabilities, manufacturing and sales of robot integration service providers, and construction and operation of robot service platforms