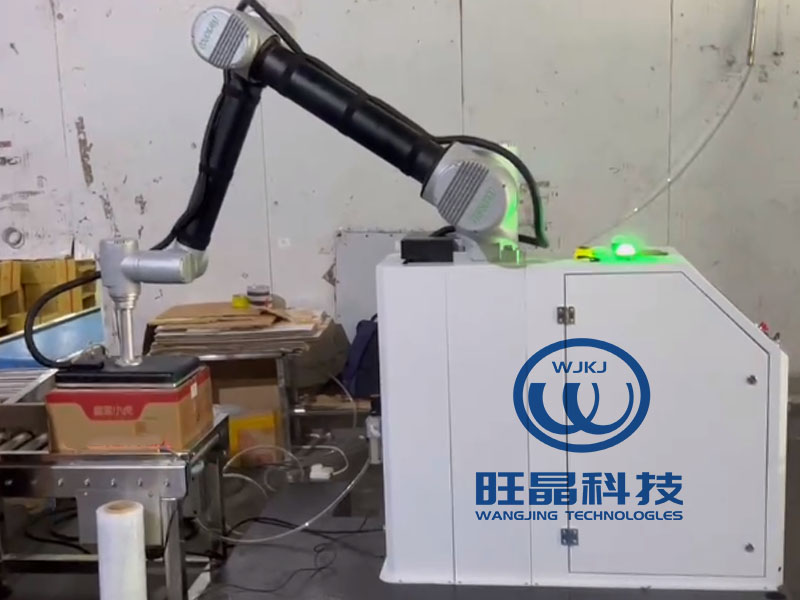

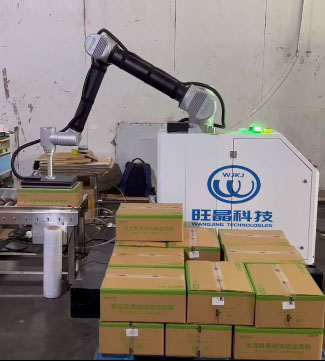

The advantage of this robot is that it can automatically identify what is a cooperative palletizing

The stacking work is completed in the form of a mechanical arm. Stacking is one of the most promising cooperative robot applications, but before introducing in detail, let's start with a simple definition. Palletizing or palletizing refers to the act of placing products on pallets for shipment or storage in the logistics supply chain. Ideally, products should be stacked in a way that maximizes the weight and volume of products under load, and they should be stable enough to prevent products from moving, dumping or squeezing each other.

At present, most digital stack applications are done manually. However, as workers become more and more difficult to find, once we find them, don't talk about piling boxes all day long, because they will leave. Today's manufacturers are introducing robots into their workshops to make up for the shortage of employees who can and are willing to do this work. Assuming that the flow of boxes and pallets is constant, the automatic stacking process can be repeated endlessly. Some industries use robots for one-step production, such as feeding injection molding machines or CNC machine tools. When production runs around the clock, the collaborative palletizing robot allows you to minimize cycle time and run the process continuously by removing parts from the machine's work area. Other companies will use online systems designed and created to accommodate a large number of products per hour. Strictly speaking, robots "cooperate" because they can detect abnormal activities in the environment through force limitation or visual monitoring. These sensors allow humans and robots to cooperate without any physical isolation. Most importantly, cooperative robots meet the fourth standard of safe cooperation, namely power and power limit. In fact, all cooperative robots have powerful sensors in their joints, which can stop moving when they are hit. This allows you to run the robot at full speed without worrying about the potential danger of the kinetic energy carried by the manipulator. There are various cooperative robot models on the market. However, no matter which brand you choose, you should always carry out risk assessment during the implementation of the unit to ensure that the surrounding environment of the cooperative robot and the cooperative robot itself are safe. Back to the numerous fascinating options in stacking and the market, it seems very simple to choose a robot to stack boxes, which may be a complex matter. You need to consider payload capacity, speed, range, programming, etc.

1. Pallets: There are many different kinds of pallets on the market, such as wood, plastic, paper/cardboard, metal and aluminum. Size is also a big topic, and the standards may vary depending on where you are in the world.

2. Conveyor belt: It is used to transfer boxes to robots. We can say that there are countless conveyor configurations on the market. They have now been adjusted and optimized for specific industries. Make sure you select the model that is appropriate for your business.

3. Controller: coordinate the movement of the machine. You can also insert other components here, such as security scanners or light screens.

4. Operator: operate the robot (in the robot unit).

5. Grab: Grab the box from the conveyor belt and put it on the tray. In general, vacuum fixture is the best choice for box selection. Make sure the suction cup configuration is appropriate for your case and payload, otherwise you may encounter problems with pickup reliability and repeatability.

6. Teacher: A handheld device used to program robots. We recommend that you always have a protective case for your teaching pendant. It's like your mobile phone. You don't want to drop it.

7. Status light: indicates different states of the machine, namely: tray ready, tray full, error, emergency stop, etc.

8. Cable management system: used to protect cables connecting robots and other parts. It also prevents the cable from being pinched.

9. Robot: perform the action of stacking boxes for the operator.

10. Sefeguarding: It is not always required, but it must always be considered through risk assessment analysis. They usually come in three forms: fences, light curtains, and area scanners. In the process of cooperation with the stacking robot, only two points need to be located