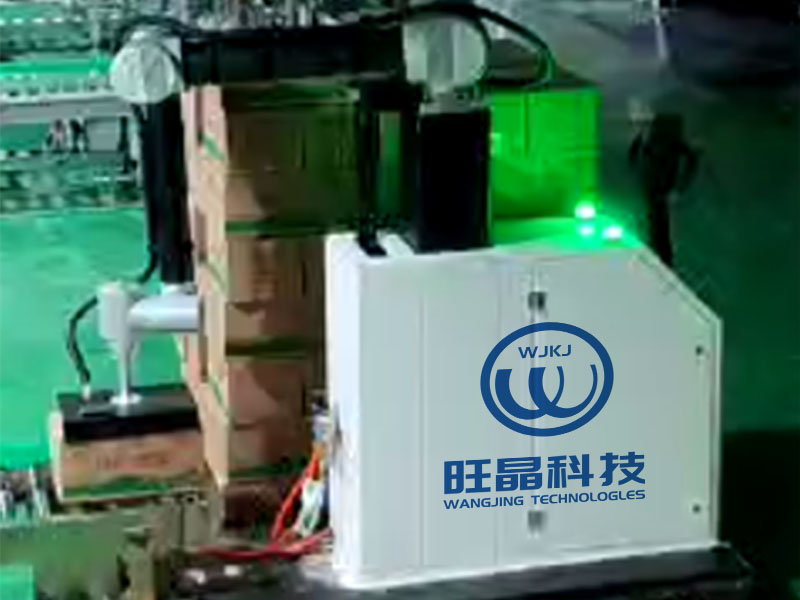

This technology is fully automatic palletizer, which is a good helper for enterprise production

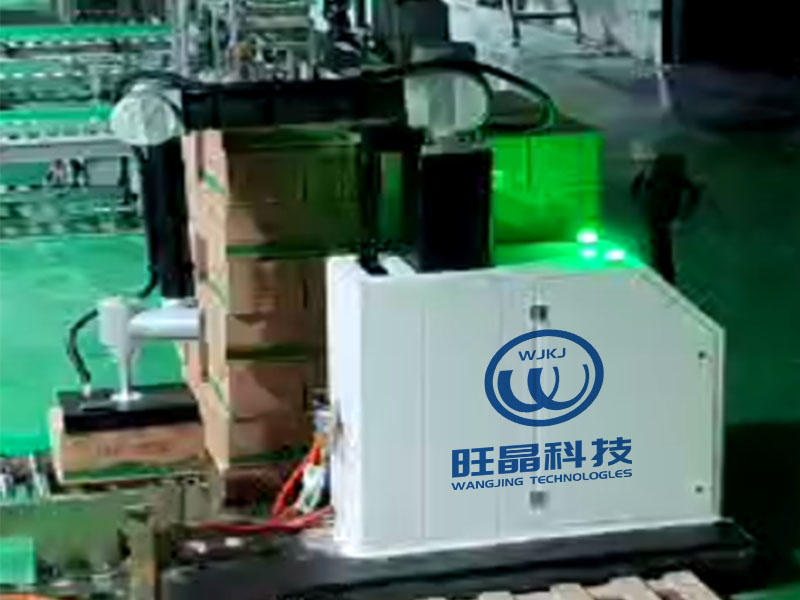

Many people have only a general understanding of stackers. They believe that the stacker is a simple mechanical equipment used for handling and stacking goods. In fact, the stacker is not just a simple mechanical equipment. Many production workshops have palletizing robots to load, unload and stack goods. The use of palletizing robots is several times more efficient than traditional labor, but it can also reduce the human cost of enterprises.

Since the birth of the industrial automatic palletizer, it has solved the problems of mass handling, packaging and stacking of workpieces. Therefore, the stacker is not just a simple stacker. It is a multifunctional production assistant.

The automatic stacking manipulator can imitate some technical actions of the hand and arm to develop functions, as an automatic operation experimental device that can grasp and carry objects or operate management tools according to fixed system programs. The automatic stacking manipulator is an industrial robot that appeared earlier. It can replace the heavy labor of people and realize the mechanization and automation of enterprise production. It is widely used in transportation and palletizing of automobile, building materials, food, packaging, chemical industry, grain and oil, hardware, machinery and other industries.

The automatic stacking manipulator is mainly composed of an actuator, a driving mechanism and a control system. The hand is a component used to grasp the workpiece (or tool). It has a variety of structural forms according to the shape, size, weight, material and operation requirements of the grasped object. Such as clamping type, supporting type and adsorption type. A motion mechanism, which enables the hand to complete various rotations (swings), motions or composite motions to achieve the specified actions, and change the position and posture of the grasped object.

Automatic industrial stacker is also a high-tech electromechanical product integrating machinery, intelligence and electronic information technology. And with the continuous progress of modern science and technology, the future stacker will be more intelligent, convenient, easy to operate, and more adaptable.